The standard power supply of our company's cranes is three-phase 380V (±10%, the lower limit of peak current is -15%), 50Hz, and we can also customize to three-phase power supply below 690V and a frequency of 50-60HZ, even single-phase power supply according to customer requirements in different countries and area.

With the continuous development of overseas markets of Sinokocranes, in order to meet the actual needs of users in various regions of the world, the R&D department of Sinokocranes has carefully researched, updated and improved the power supply voltage/frequency adaptability of the whole product line has been tested and accepted, and the whole product line has been officially put into production.

After improvement, the applicable power supply voltage/frequency table is as follows:

| Nominal Voltage | 220 V | 380 V | 460 V | 575 V |

| 208~230 V/50Hz | 360~400 V/50Hz | 440~480 V/50Hz | 575~600 V/50Hz | |

| 208~230 V/60Hz | 360~400 V/60Hz | 440~480 V/60Hz | 575~600 V/60Hz |

Among them: 360~400 V/50Hz and 440~480 V/60Hz are commonly used domestic standard power supply voltage/frequency; component prices are applicable to the standard design and price.

In addition to the above two standard ranges, other products with supply voltage/frequency requirements are applicable to customize design and price.

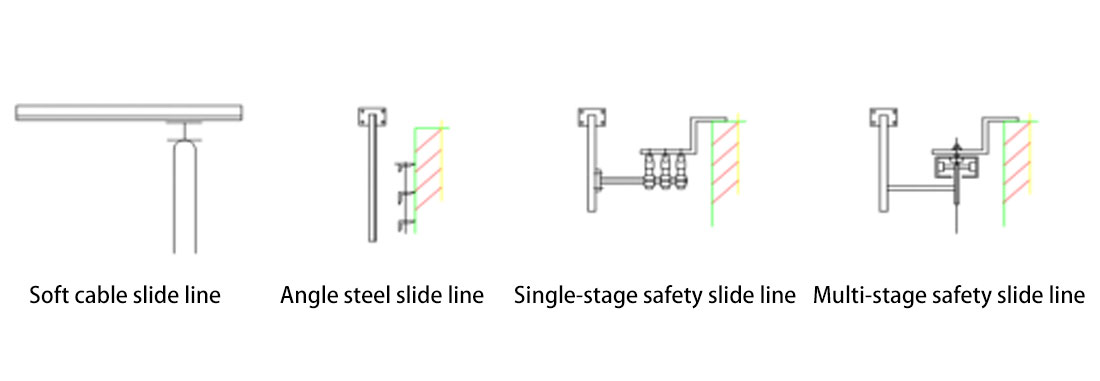

The commonly used power supply methods for single-girder overhead cranes are divided into two categories, sliding contact line power supply and cable line power supply. The two power supply methods have their own applicable places. For example, the sliding contact line is very convenient for maintenance and inspection, and occupies a relatively small space, but the weather resistance of the operating environment temperature is slightly insufficient, and the flexibility is poor; the cable line It can be continuously bent and used with the equipment, and has better flexibility. Due to the protection of the outer layer of insulating glue, the wear resistance, oil resistance and corrosion resistance are relatively stronger.

There are also round wires and flat wires. The number of bending times of the flat wire is greater than that of the round cable, and the service life is long. According to the characteristics, the flat cable is mainly used for mobile laying, the round cable is used for fixed laying, and the round cable with small cross-sectional area can also be used.

When arranging crane cables, it is necessary to ensure that the length of each cable is flat, the pressure plate is crimped firmly, and the outer diameter of the same layer of cables is as close as possible to avoid excessive stress on one or a few cables. The cables that need to be suspended should be arranged with a wire harness, so that the wires are neat and orderly. During operation, when the distance between two adjacent suspension cable trolleys makes the angle between the suspension cables close to 120°, the traction wire rope should be completely straightened and stressed.

|  |

During the application process, some customers also value the advantages of the power transmission rails of the trolley line, such as good electrical conductivity, fast heat dissipation, and low impedance value, configure the corresponding software and hardware. Sinokocranes introduces product features to customers, and recommends feasible solutions for customers' production value. The right to choose is in the hands of customers. We provide not only products, but also strive to provide better services.