Workstation cranes are lightweight overhead lifting systems designed for precise material handling in manufacturing, assembly lines, and warehouses. Unlike traditional bridge cranes, they operate in confined spaces with smooth maneuverability, reducing worker fatigue and increasing productivity.

Sinokocranes Workstation Tailored To Your Needs

Sinokocranes offers customizable workstation cranes designed for efficiency and safety. With modular designs (125kg-5ton capacity), they fit various industries like automotive and warehousing. Choose steel or aluminum tracks, freestanding or ceiling-mounted options. Easy to install and operate, these cranes reduce worker fatigue while improving productivity.

Types of Workstation Crane Systems We Offer

Aluminum Workstation Crane Systems

Lifting capacity: 125kg-2t

Feature: Lightweight, Smooth Operation, Low Rolling Resistance.

Applications: The automotive industry and other fields with strict requirements.

Learn More Get a QuoteFree Standing Bridge Crane

Lifting capacity: 125kg-5t

Feature:

Can be installed in any area.

High load capacity.

Easy to assemble.

Ceiling Mounted Crane System

Lifting capacity: 125kg-3.2 ton

Feature:

Flexible Hanging Method

Space-saving.

High utilization of workshop space.

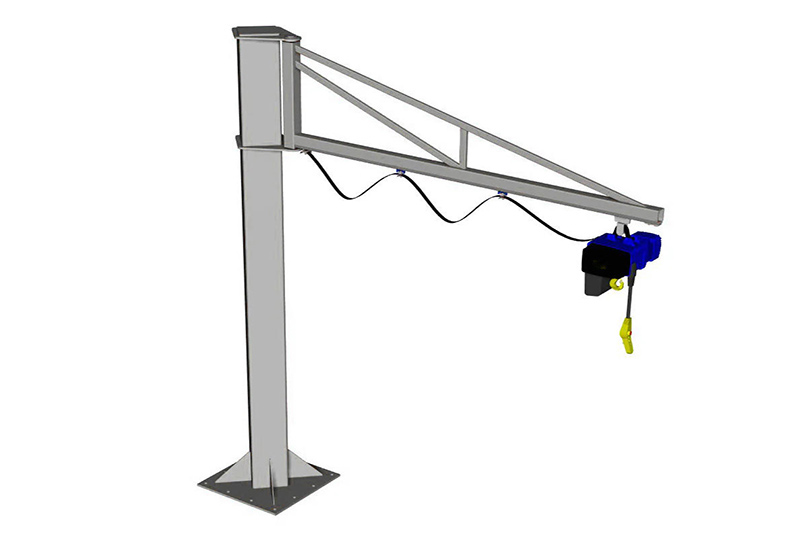

Free Standing Jib Crane

Lifting capacity: 0.25t-5t

Feature: Different structural designs for different situations.

Applications: Used in production lines and warehouses, this equipment improves efficiency and working conditions.

Learn More Get a QuoteHangar Cranes

Lifting capacity: 1t-32t, customized

Span: 5-72m

Application: Aircraft Maintenance Hangar

Learn More Get a QuoteLightweight Stacker Cranes

Lifting capacity: 125kg-500kg

Application: Suitable for conveying, sorting, storage and storage of parts, containers and stacking pallets.

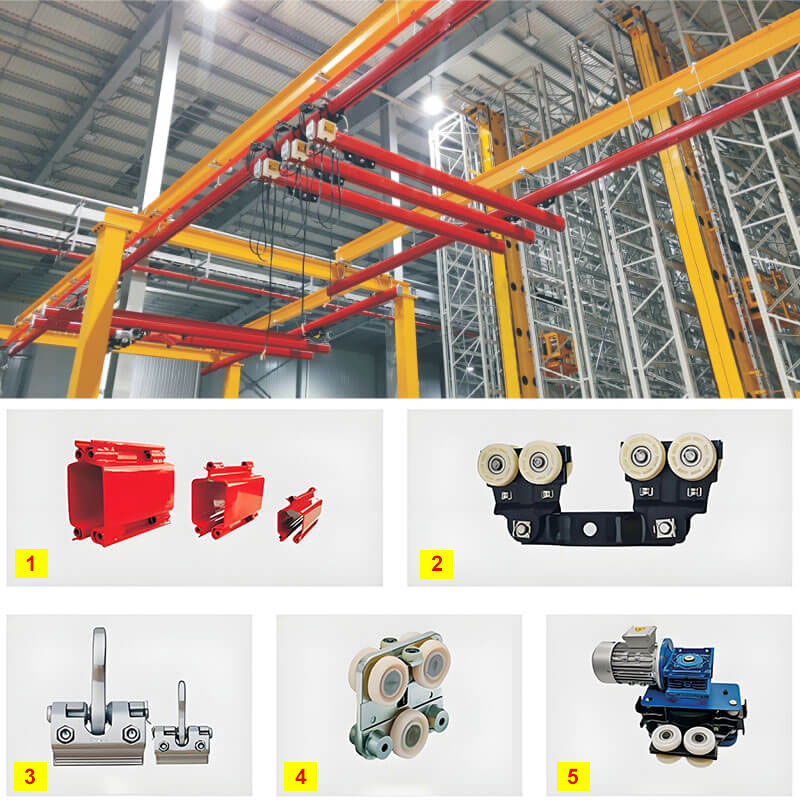

Sinokocranes Workstation Crane Components

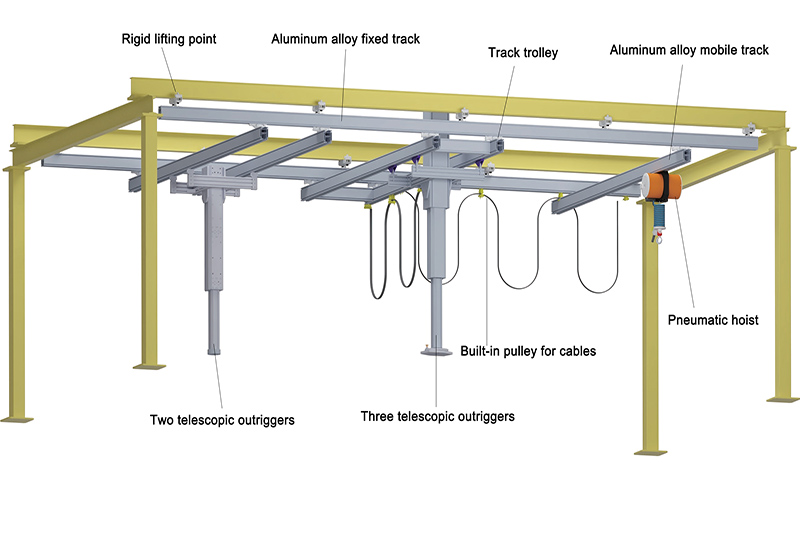

Rigid Light Crane System

1. Electric Drive Unit

2. Profiled Rail Trolley

3. Hoist Trolley

4. Trolley

5. Suspension Clamp

All standard components of the KBK-C system can be freely combined, allowing flexible track layouts to meet workshop requirements.

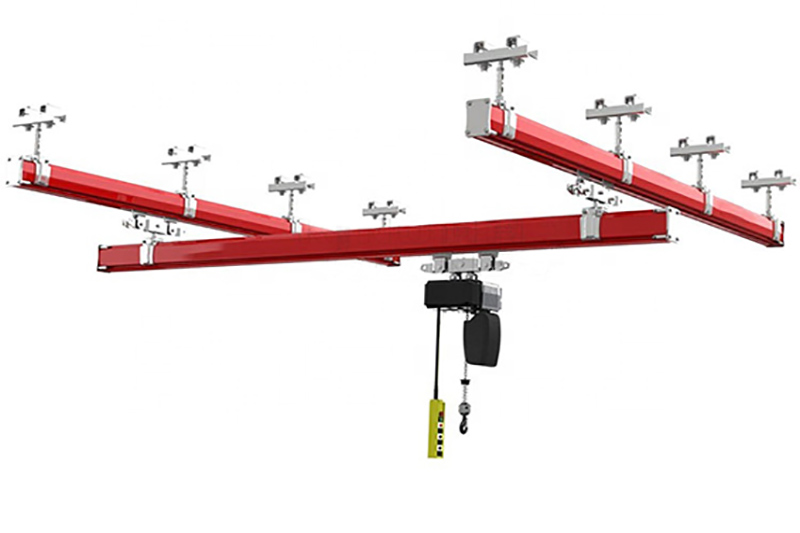

Flexible Suspension Light Crane System

1. Suspension Crane Track

2. Manual Trolley

3. Suspension Clamp

4. Aluminum Alloy Guide Wheel

5. Electric Drive Unit

Sinocranes Workstation Suspension Cranes offer flexible, cost-effective lifting solutions with modular designs, vibration damping, and easy reconfiguration to optimize workshop efficiency.

Free standing cranes can be flexible manual, semi-automatic or automatic operation according to the working conditions. Sinokocrane make it free standing crane modular design, the standard profiles are bolted together, easy to installation & transportation.

Free standing crane from SINOKOCRANES can be suspended simply from the building roof directly to the required destination. Then the free standing crane allows overhead handling and achieves maximum efficiency workspace without runway columns.

Type of Workstation Crane

Sinokocranes offers a comprehensive range of customizable workstations crane solutions, including freestanding monorail cranes, suspension monorails, overhung/extending cranes, and single/double-girder systems, all tailored to optimize your production workflow.

Flexible Beam Free Standing Bridge Crane

Light weight free standing bridge crane design is constituted by KBK track, electric chain hoist and installation components.

Learn More Get a QuoteMonorail Suspension Overhead Bridge Crane System

The KBK suspended monorail crane in the KBK light crane system can be tailored to your specific needs for linear aerial handling. By assembling different options, unique advantages can be demonstrated.

Learn More Get a QuoteFree Standing Workstation Bridge Crane

Enhance your material handling efficiency with a Free Standing Workstation Bridge Crane. This versatile and ergonomic crane provides a cost-effective and space-saving solution for efficient material handling within workstations. Contact us.

Learn More Get a QuoteWorkstation Cranes Project Case

Sinokocranes offers a comprehensive range of customizable crane solutions, including freestanding monorail cranes, suspension monorails, KBK overhung/extending cranes, and single/double-girder systems, all tailored to optimize your production workflow.

Steel Billet Handling Cranes

Billet Cranes with lifting magnets is suitable for stacking hot rolled steel billets. Get free quote.

Learn More Get a Quote450 ton Overhead Crane

Our 450 ton overhead crane is a high-capacity lifting solution designed for industries requiring efficient handling of heavy loads.

Learn More Get a Quote