Overview:

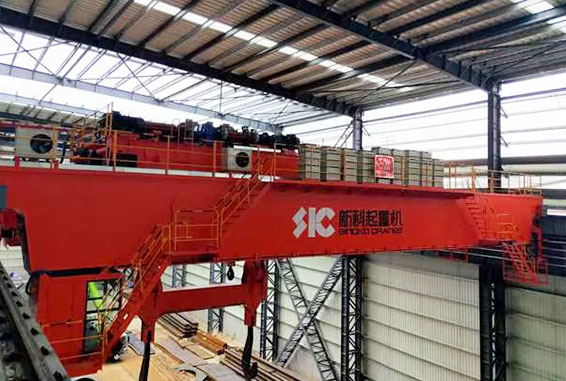

The 450 ton overhead crane is a high-capacity lifting equipment that utilizes either a double girder design, depending on the specific requirements of the project. It is engineered to handle heavy loads with precision, ensuring smooth and safe material handling operations.

All the technology and design is based on the International standard: DIN, FEM, ISO. In addition, its special travelling structure is also your best choice. The electric double girder crane is applied to handle materials in many industries' workshop and warehouse, such as machinery manufacture, warehouse, logistic, food, paper making, electronics industries workshop and other material handling situations.

Features

Main Beam:

The main beam features a box-type structure, ensuring easy transportation and stability during crane operation.

High-strength bolt connections between the main beam and end beams guarantee structural integrity.

End beams are constructed from rectangular steel pipes and undergo precise CNC machine tool positioning processing.

Each end beam is equipped with a double wheel rim wheel group, buffer, and anti-derailment protection device.

Hoist:

Maximum space utilization allows for efficient use of available workspace.

Precise operation enables accurate positioning of loads with minimal errors.

Low maintenance cost reduces overall maintenance expenses.

Minimal fault downtime ensures continuous productivity.

Minimum hook limit space and distance optimize the use of vertical space.

Standard World-Renowned Brands:

SEW and ABM three-in-one type motor for reliable and high-performance operation.

Schneider electric parts ensure quality and durability.

Drum, Steel Wire Rope, Rope Guide:

High-quality seamless pipe drum processed by CNC machine tool to prevent rope loose and tangling.

High-strength imported wire rope with excellent safety performance and extended service life.

Standard rope guide made from engineering plastics with abrasion resistance and self-lubricating properties.

Lifting Mechanism Gear Box:

Aluminum alloy material for lightweight and corrosion resistance.

Semi-grease lubricant in a fully sealed box ensures full lubrication and maintenance-free operation.

Surface hardening and high-precision grinding of gears ensure stable running and reliability.

ABM three-in-one type drive provides stable operation, low noise, and reliable quality.

Inverter Control:

Inverter control system allows for smooth and precise speed control of the lifting mechanism.

Ensures stable running and enhanced safety during crane operation.

Advantage of 450 ton Double Girder Overhead Crane

1. Compact design allows for optimal utilization of work areas, maximizing space efficiency.

2. Easy load control and precise positioning of loads for efficient material handling operations.

3. Superior safety and reliability ensure secure lifting operations and minimize the risk of accidents.

4. Minimum and easy maintenance requirements reduce downtime and increase productivity.

5. Comprehensive solutions for all your crane and hoist needs, providing a convenient "One-Stop Shop" experience.

Experience the benefits of our compact, reliable, and efficient crane solutions. Contact us today to discuss your specific requirements and find the perfect lifting solution for your needs.

Specification

| Span | 22.5m - 37.5m |

| Crane Weight | 140t - 210t |

| Max. Wheel Load | 705kN -769kN |

| Min. Wheel Load | 80kN - 120kN |

| Lifting Speed | 0 - 1.0 m/min |

| Trolley Speed | 0 - 18 m/min |

| Bridge Speed | 0 - 32 m/min |

Contact us today to discuss your heavy lifting needs and explore the possibilities of our 450 ton overhead bridge crane. Our team of experts will provide personalized solutions and ensure efficient and reliable lifting operations for your industry.

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

The 450-ton Overhead Crane is designed for heavy-duty lifting in industries like steel, shipbuilding, construction, and large manufacturing plants.

The Sinoko 450-ton Overhead Crane is capable of lifting up to 450 tons, making it ideal for handling extremely heavy loads with precision and safety.

Key features include high load capacity, advanced safety systems, durable construction, and customizable configurations to fit various industrial applications.

Yes, the Sinoko 450-ton Crane can be customized in terms of span, lifting height, control options, and additional features to suit your specific lifting requirements.

Regular inspections, lubrication, and maintenance of electrical and mechanical components are recommended to ensure optimal performance and extend the crane’s lifespan.

To order, contact Sinoko for a consultation. Our expert team will handle installation, testing, and provide necessary training to ensure smooth operation.