Overview:

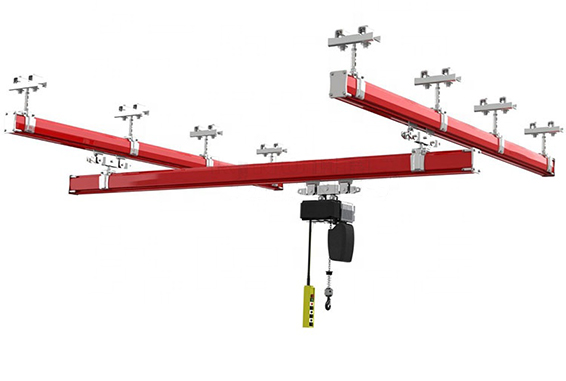

Flexible beam free standing bridge crane is economical modular light crane system, which design is constituted by KBK track, electric chain hoist and installation components. The free standing bridge crane can be a very simple equipment with 2 straight rails, also can be very complex suspended monorail system. free standing bridge crane has simple operation of manual operation also has complex operation such as automatic system operated by compute integrated control.

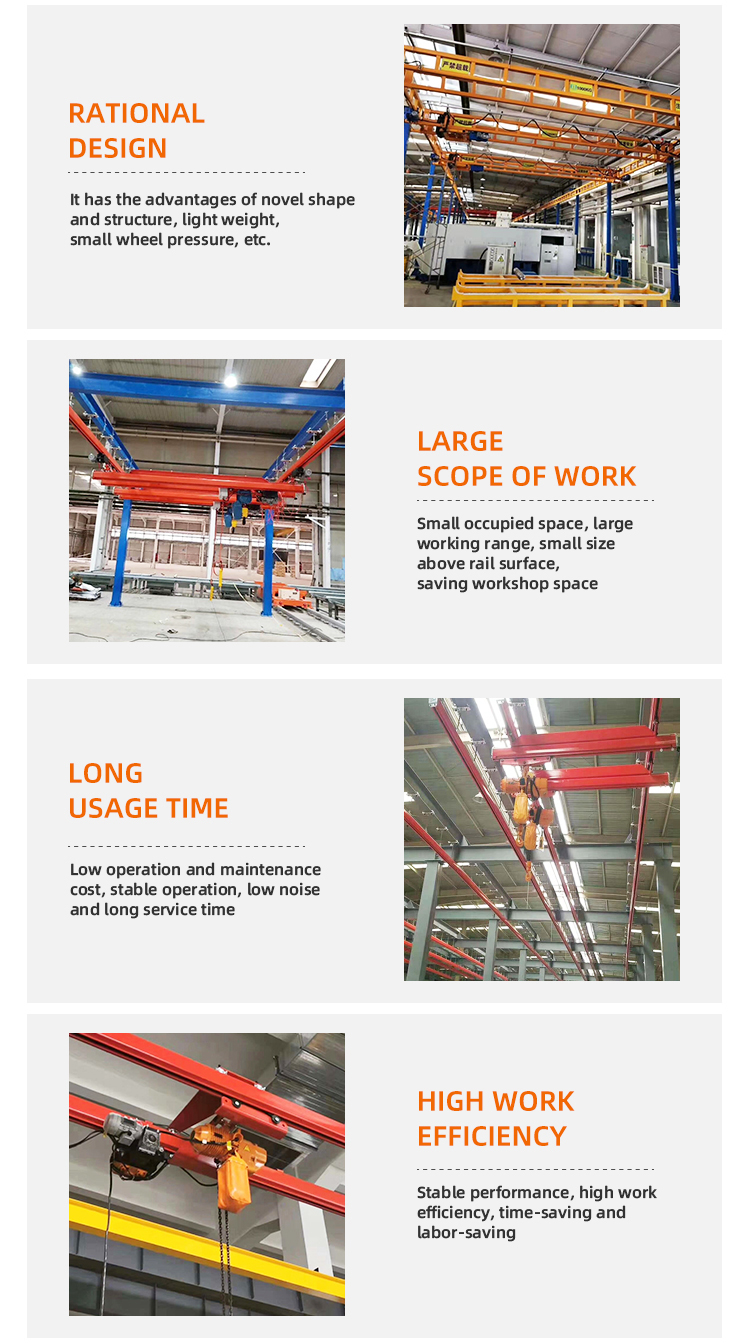

Features

Specification

| Lifting mechanism | Electric Hoist |

| Control method | Pendant Control |

| Crane type | KBK Cranes |

| Application | Indoor |

| Crane Material | Q235 Carbon Steel |

| Capacity | 0.5-5 Ton |

| Work Duty | A3-A5 |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Requires 0 floor footprint - installs directly on existing structures. Minimal clearance: • Vertical: 6" below ceiling beams • Horizontal: 15cm from walls/equipment • No foundation work needed

A: Perfect for precision assembly: • ±2mm positioning accuracy with VVVF control • 500kg-5t capacity covers most engines • Rotating KBK trolleys for 360° component access

A: 70% lower energy use due to: • Regenerative braking system • LED task lighting (500lux) • Standby mode (<50W power draw)

A: Modular KBK tracks allow: • Add/remove spans in <4 hours • Relocate entire system in 1 day • Tool-free connection system

A: Yes. FDA-compliant package includes: • IP65-rated motors (washdown-proof) • Stainless steel track surfaces • Zero-lubrication polymer bearings

A: Full CE/ISO 9001 compliance with: • Dual-limit switches (upper/lower) • Emergency stop at all workstations • Overload protection (±3% accuracy)