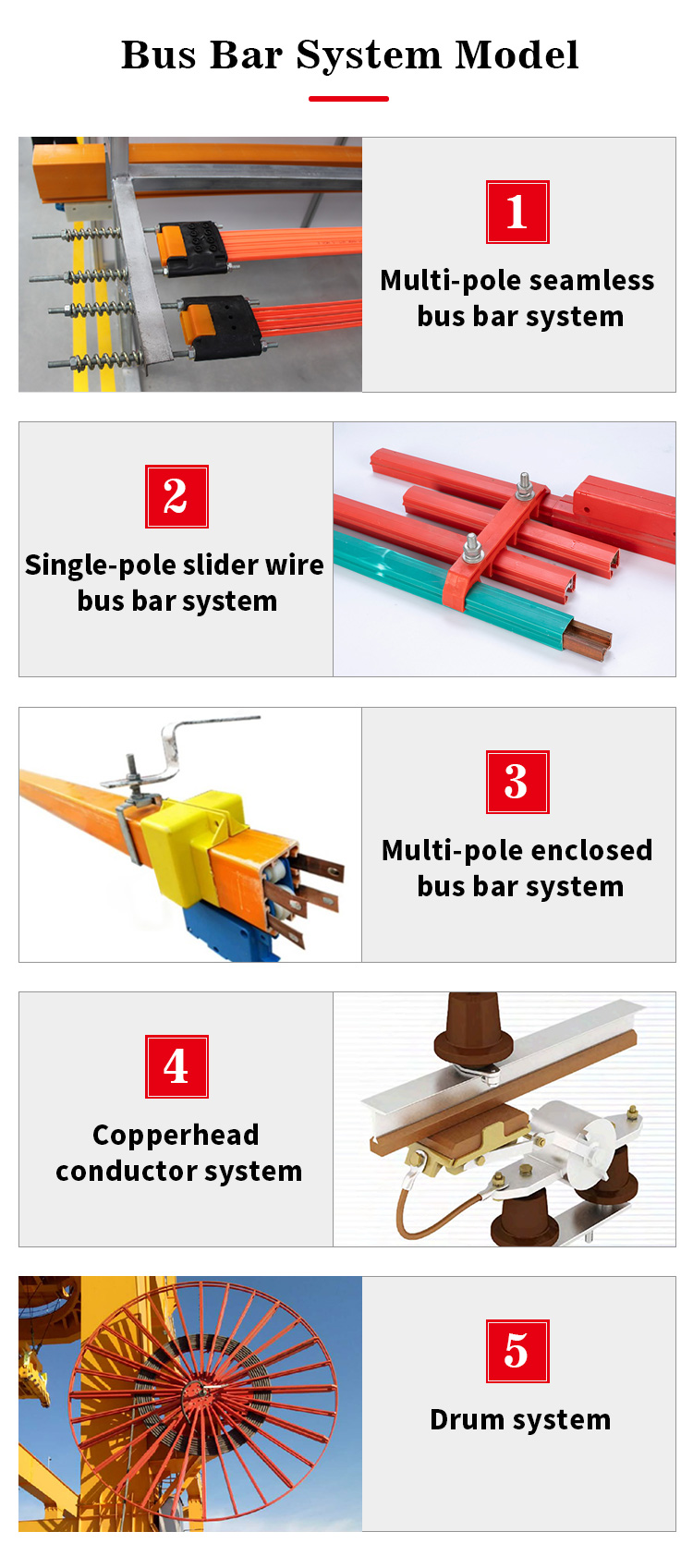

For the electric single girder crane, its operation cannot be separated from the application of any accessory. Take the bus bar as an example. Without its current transmission, the equipment is difficult to operate. Since the bus bar used in different occasions are different, today Kinocranes will introduce you to the use of various bus bar(also called power conductor line for crane)

Ⅰ.Single-pole slider wire bus bar system

The single-pole energy-saving combined bus bar is a very widely used bridge crane bus bar on the market. The conductor material is conductive aluminum or red copper, among which aluminum conductor line have a high market share. Its products have good electrical conductivity, high cost performance, and reliability. The combined design is convenient for installation and maintenance, and has a wide range of applications. It can be applied to a variety of indoor and outdoor environments. The current range is from 200A-2000A to choose, which can meet the needs of different devices for products.

Ⅱ.Tubular multi-pole bus bar

The tubular bus bar embeds the conductor in the polyvinyl chloride shell, which is convenient and simple to install. The use of copper as the bridge crane bus bar conductor has good conductivity, but is limited by the inner groove of the shell. And is mostly suitable for mobile devices with lower power.

Ⅲ.High temperature rigid bus bar

The bus bar of high temperature rigid crane is composed of copper conductor and steel structure frame or aluminum profile. It has high mechanical strength, good rigidity, and can withstand large-strength impact current. It uses copper as a conductor and can carry currents above 3000A. Rigid bridge crane bus does not The outer shell serves as protection, with large heat dissipation area, low temperature rise and long service life. Due to the special material, it can be used in high temperature, high pressure, high humidity, strong corrosion, and dusty environments, such as steelmaking, metallurgy, chemical industry, docks and other industries.