Factory-Direct heavy lifting solutions designed for Steel Plants, Shipyards, and Workshops. CE/ISO Certified with Global Installation Support.

Response within 24 hours

We understand the critical issues you face when sourcing industrial crane solutions

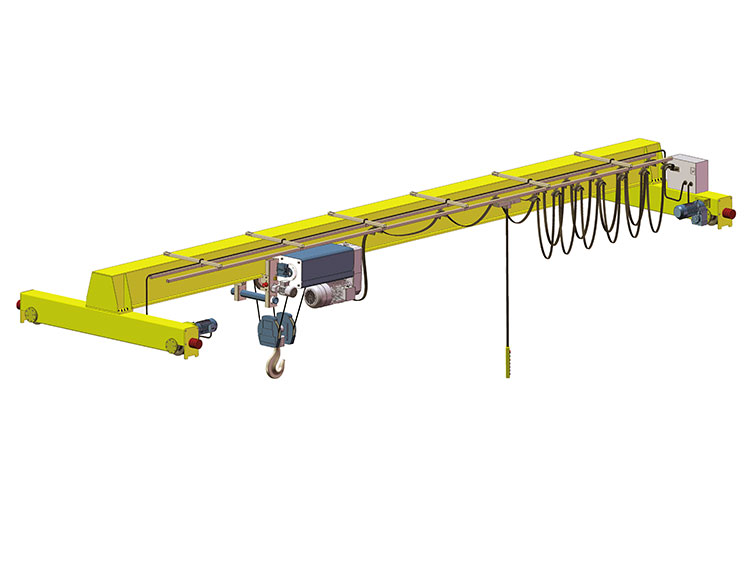

From light workshop handling to heavy-duty lifting, our EOT crane types deliver reliable solutions across industries.

From light workshop handling to heavy-duty lifting, our EOT crane types deliver reliable solutions across industries.

Siemens/Schneider brand, IP55 protection, F class insulation.

Hydraulic thruster brakes ensure smooth and safe stopping.

High tensile steel wire rope, breakage-resistant design.

Double protection against over-lifting and lowering.

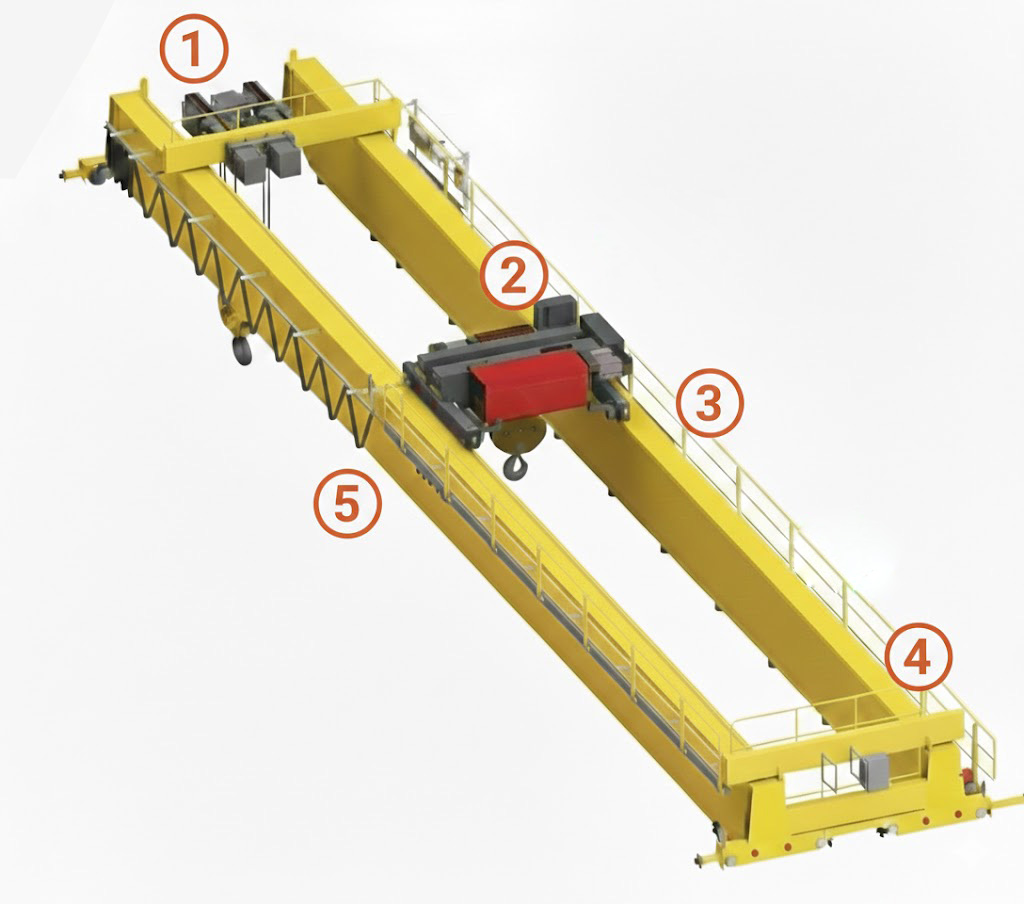

Every component is engineered to solve specific operational challenges

Stable support, precise alignment, easy installation

Compact, robust, overload-protected

High-strength, low-deflection, durable steel

Forged steel, smooth travel, low friction

High-torque, energy-efficient, low-noise

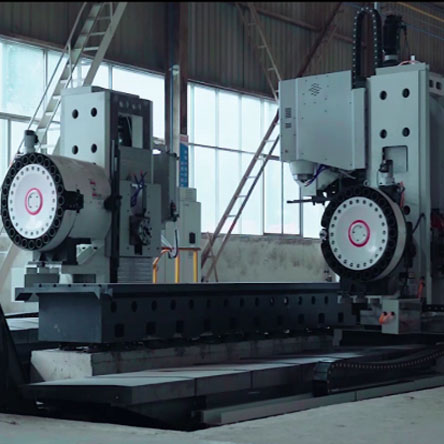

From seamless girders and robotic welding to precision CNC machining, our manufacturing process is designed to deliver cranes that are stronger, safer, smoother, and delivered on time.

Eliminating joints to prevent fatigue cracks and corrosion, extending service life by over 30%.

80% robotic coverage ensures zero hidden defects in welds, delivering aerospace-grade safety.

High-precision machining eliminates "rail gnawing" and cuts long-term maintenance costs significantly.

Optimized workflows ensure on-time delivery and offer superior cost-performance for every project.

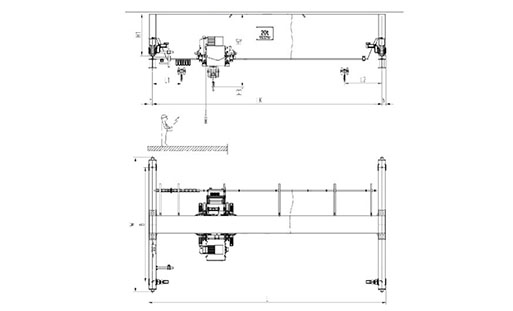

Precision-engineered specifications for demanding industrial applications

| Item | Specification |

|---|---|

| Capacity | 1t - 20t |

| Lifting Height | 3m - 18m Standard, Customized |

| Lifting Speed | 0.8 - 5m/min(Variable Frequency) |

| Work Duty | M3 - M8 |

| Span | 10.5m - 34.5m Customized |

| Rated Voltage | 220V/380V/400V/415V/660V, 50 - 60Hz, 3ph AC |

| Rail type | P22 - P38 |

Our overhead cranes are perfect for factories, workshops, steel plants, and heavy-duty lifting projects

With over 20 years of experience, we deliver excellence in engineering and service. Our cranes are operating in over 80 countries, backed by international certifications.

Tell us your requirements today. Our engineers are ready to provide a free design and quotation within 24 hours.

On-site guidance

Regular checks

Fast delivery

Online help

Tell us your requirements today. Our engineers are ready to provide a free design and quotation within 24 hours.

Detailed analysis of your lifting needs and site conditions.

Technical drawings provided for confirmation within 24 hours.

Strict production tracking and quality inspection reports.

Secure export packaging and worldwide shipping coordination.

Expert installation guidance and lifetime technical support.

From Design to Delivery

FREQUENTLY ASKED QUESTIONS