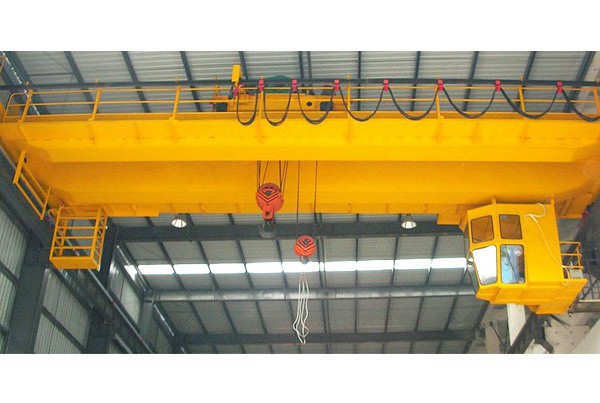

Explosion-proof Overhead Crane is a type of bridge crane, supporting the use of explosion proof electric hoist, All crane components are selected to ensure the high level of safety required for the hazardous atmospheres in chemical and petrochemical plants, oil refineries, gas power plants, wastewater treatment plants, paint shops and other industrial sites.

Most of them are used in flammable, explosive, and corrosive environments. They are in line with JB/T10219-2001 “Explosion-proof beam cranes”

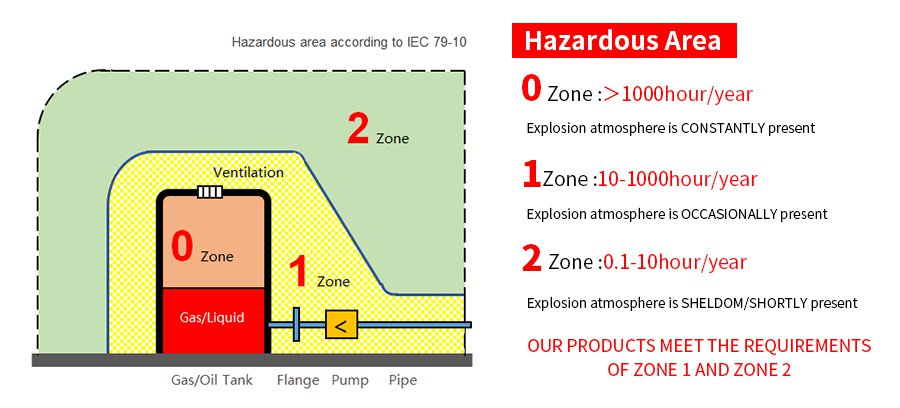

The crane is qualified inspected by inspection unit of blast-proof product which is appointed by the state. The crane has got Certification of conformity of An Instrument for Explosive Atmosphere. where has mixture of detonating gas which is composed of flammable gas or steam, whose ignition temperature team belongs to T1 ~ T4 team , and air. The applicable danger area is Area 1 or Area 2.

Gas Environment

Zone 1

A place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2

A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Dust Environment

Zone 21

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

Zone 22

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Explosion Proof Overhead Crane Features

1. Optimized design in line with FEM standards.

2. The overload protection function is usually set, 100% overload alarm, 110% overload can drop but not rise, 125% overload automatically stops.

3. Equipped with an intelligent safe operation monitoring system, which can continuously record the working status and prevent non-professional operation.

4. The controller will perform a self-check before starting, including the power supply voltage level, default phase, button zero state and the validity of each safety device.

5. The three-point support statically determinate structure reduces internal stress, and the side-mounted reducer and cantilever motor form a flexible drive system to ensure stable operation and low noise.

6. Imported motor, aluminum alloy wire drawing, good heat dissipation, overheating protection and alarm function.

7. The whole machine is maintenance-free design, with few wearing parts and convenient maintenance.

Mechanical | Electrical | ||

No. | Item | No. | Item |

1 | Overload Limiter | 1 | Main isolating switch |

2 | Limit Switch | 2 | Short-circuit protection |

3 | Interlock protection device | 3 | Under-voltage protection |

4 | Buffer | 4 | Zero protection |

5 | Rail tongs, Anchor device, | 5 | Motor overload protection |

6 | Rail clear plate | 6 | Emergency stop system |

7 | Protective cover | 7 | Current overload protection |

8 | Bus Bar preventer plate | 8 | Security chain protection |

9 | Anti-collision device | 9 | Groud protection |

Explosion Proof Overhead Crane Specification

Lifting Capacity (T) | 5 | 10 | 16/3.2 | 20/5.0 | 32/5.0 | 50/10.0 | ||||

Span (M) | 10.5-31.5 | |||||||||

Lifting height M | Main Hook | 16 | 16 | 16 | 12 | 16 | 12 | |||

Aux Hook | 18 | 11 | 18 | 16 | ||||||

Speed M/min | hoist | Main hook | A5 | 12.5 | 8.5 | 7.9 | 7.2 | 7.8 | 5.9 | |

A6 | 15.5 | 13.3 | 13 | 9.7 | 9.5 | 7.8 | ||||

Aux hook | 14.5 | 12.7 | 19.5 | 13.2 | ||||||

Trolley traveling | 38.3 | 13.8 | 42 | 44.5 | 44.6 | 42.4 | ||||

Bridge traveling | A5 | 90.7 | 90.7 | 91.9 | 91.9 | 87.6 | 74.6 | |||

A6 | 115.6 | 115.6 | 116.8 | 116.8 | 101.4 | 87.3 | ||||

Rail recommended | Trolley | 15kg/m | 43kg/m | |||||||

Bridge | 43kg/m | QU70 | QU80 | |||||||

Power Source | 380V 50HZ 3Phase or according your requirments | |||||||||

FAQs

An explosion-proof overhead crane is used for lifting and transporting materials in hazardous environments where flammable gas, vapor, or dust may be present, such as chemical plants, oil refineries, gas power stations, and paint workshops.

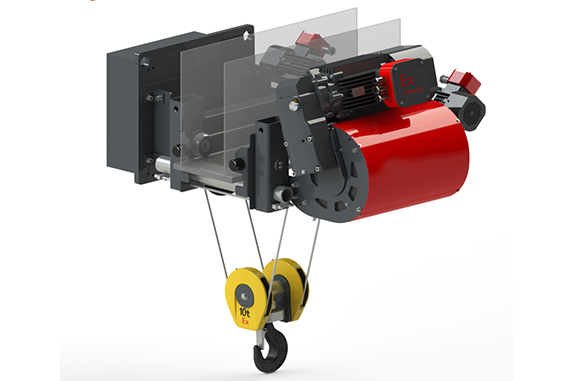

It is equipped with an explosion-proof electric wire rope hoist or open winch hoist designed for hazardous areas to ensure safe operation.

Yes, we customize the explosion-proof grade, working class, lifting speed, and control systems according to your site’s explosion-proof requirements and operational needs.

Our cranes comply with GB3836.1-2010, GB3836.2-2010, IEC, ATEX, and other relevant international explosion-proof standards.

Related Explosion Proof Overhead Crane Products

Discover more explosion proof cranes and accessories, including explosion proof electric hoists, single girder cranes, double girder cranes, and gantry cranes to meet safe lifting requirements in hazardous environments.

Explosion Proof Electric Wire Rope Hoists

Ensure safety with our Explosion-Proof Electric Wire Rope Hoists. Ideal for hazardous environments. Request a factory price quote today!

Learn More Get a QuoteHB Type Explosion Proof Crane Explosion Proof Wire Rope Electric Hoist

Explosion Proof Wire Rope Electric Hoist

Learn More Get a QuoteElectric Explosion Proof Chain Hoist

The explosion-proof electric chain hoists produced by our company are verified through safety explosion proof. Get free quote.

Learn More Get a Quote