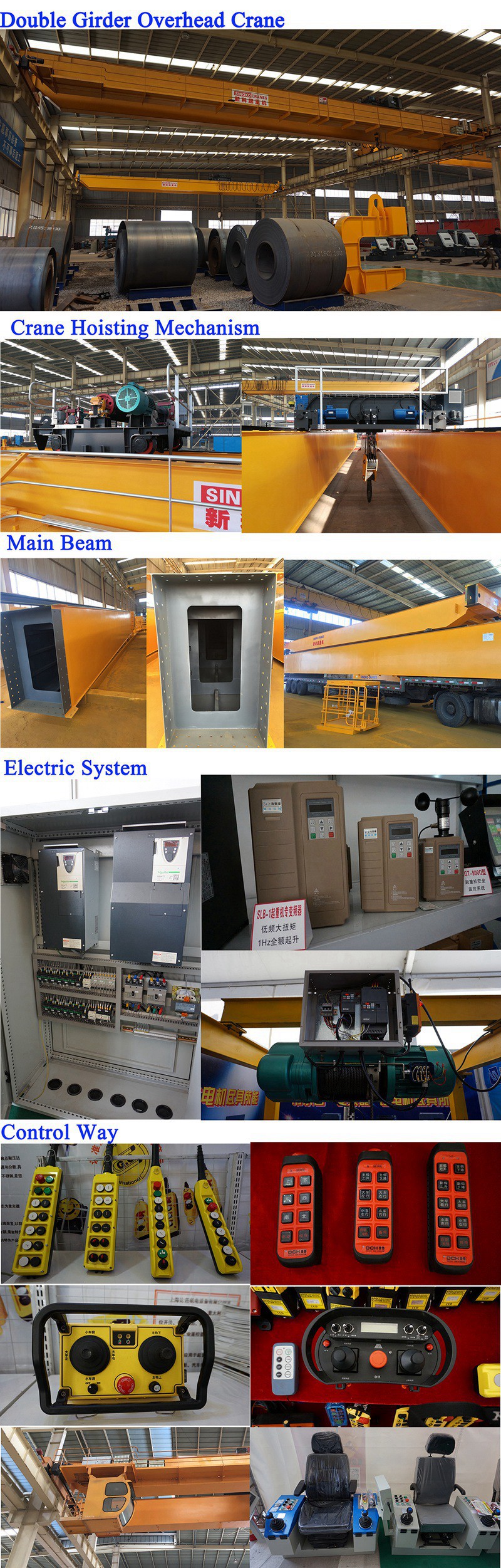

QD-double Girder Overhead Crane can be customized to meet specific customer needs, including the span length, lifting height, and lifting capacity. It can also be equipped with various accessories, such as grab buckets, magnets, and spreader bars, to handle different types of loads.

1. Design: Compact dimensions, low weight, easy to operate and easy to maintain, modular design with direct fits between components

2. Motors: Crane uses sturdy cylindrical/ conical rotor pole-changing motors with elegant continuous cast aluminum sections, integrated safety brakes insulation class F, IP54 protection

3. Gear Boxes: Precision flat helical spur gear units in light alloy housings with case-hardened gears, high-grade surface treatment and permanent oil/grease lubrication

4. Brakes: Single/ Dual-disc electromagnetic DC brakes featuring automatic braking on power failure. Environmentally sound brake linings designed for approx. 1 million braking operations allow long maintenance intervals

5. Electrical Panel: Modular design, covering a very wide operating range. The systems are designed for ease of installation & maintenance and reliable operation, with fuse-less circuitry, ducted wiring and non-screwed terminals. Each drive group is equipped with a motor overload protection device to provide effective protection against inadmissible overloading

6. Painting: Every component & part is thoroughly scrubbed & painted with two coats of primer before assembly & two coats of synthetic enamel after testing

7. Limit Switches: To prevent over hoisting & over lowering of hook

8. Push Button Stations: Extra light, handy, easy to operate, aluminum, fabricated from extruded section.

9. Soft Starts : Electric / Electronic soft start modules electrically coupled to the long travel drives to achieve jerk free, cushioned & smooth starts

10. Maintenance Platform With Hand Railing : Easy, simple and safe maintenance of the crane extended partially or totally along the girder