Coil handling overhead cranes are specialized cranes designed for the handling of steel coils in industrial environments. These cranes are used primarily in steel mills, coil storage facilities, and other industrial settings where steel coils need to be moved, stored, or transported.

The primary purpose of coil handling overhead cranes is to lift and transport steel coils of varying sizes and weights. These cranes are typically equipped with specialized lifting devices such as C-hooks or lifting magnets that are designed to securely grasp and lift steel coils.

Coil handling overhead cranes are also designed to operate in tight spaces and with high precision, making them ideal for use in environments where space is limited or where precision is required.

Smart coil lifting overhead crane is made for coil plant or storage use. Overhead crane scheduling should have functions of automatic control, location reservation, coordination linkageof multiple crane, safety path planning, collision avoidance control and scheduling optimization.

Crane automatic control Position control:

Technical requirement of Smart control system:

Distinguish | Product Name | Unit | Qty. |

EOT Crane | Crane LAN PC | set | 1 |

Crane Control PLC I/O Module | set | 1 | |

Measuring coil height encoder(Encoder) | set | 1 | |

Laser range finder to measure cross-line distance | set | 1 | |

Laser distance measuring instrument to measure distance | set | 1 | |

Angle measurement sensor | set | 1 | |

Vehicle shape recognition | Laser scanner | set | 1 |

Laser pen | set | 1 | |

Net | Wireless communication device(AP) | set | 1 |

Photoelectric converter (Fiberoptic Converter) | set | 1 |

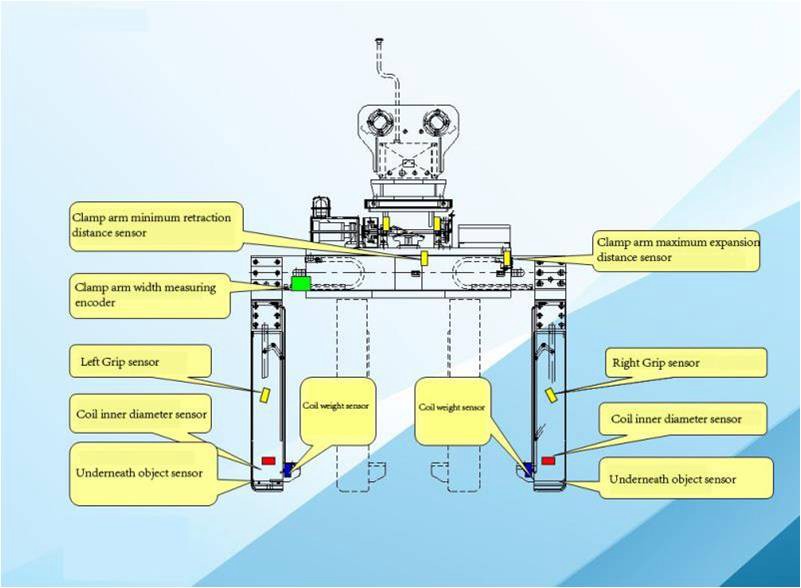

Clamp technical requirements :

The clamp should have the functions of automatic ranging and automatic control, sensing, communication etc., It can automatically run in stable working environment under the existing warehouse. Through identifying instructions issued by the system and combining with automatic decision logic, the clamp can achieve accurate opening, closing, Turning claw movements under the condition that coils will not be damaged and overall work efficiency not be affected.