SQ type manual overhead crane mainly use in no power warehouse, working shop and equipment repair places where there is no necessary requirements on speed and power.

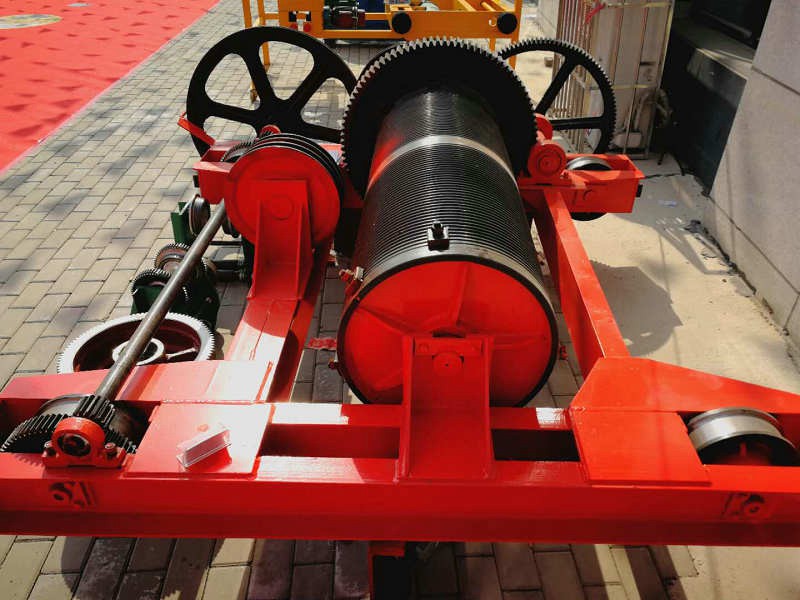

Manual Overhead Crane Main Parts

Manual Overhead Crane mainly include the following 4 parts:

a. Main Beam

b. Drive and driven wheel

c. Transmission mechanism

d. Trolley

Manual Overhead Crane Installation

The following conditions must be met when installing the manual overhead crane:

a. Allowable deviation of rail joints, height difference should not exceed 1mm, gap is less than 2mm.

b. Track gauge K is less than 12m, the allowable deviation is 6mm, the track gauge LT is greater than 12m, and the allowable deviation is 18mm.

c. Permissible deviation of track elevation is 1/1000 of the track length

d. Allowable deflection of track is 3mm.

All lubricating devices on the manual overhead crane and bearings on the drive shaft need to be filled with lubricating oil (dry oil) once every six months.

Manual Overhead Crane Using Attentions

During use, the manual overhead crane should be inspected every time to observe whether the machine has abnormal sound and whether the operating performance is sensitive. Check the crane's track every six months without loosening, deformation, etc.