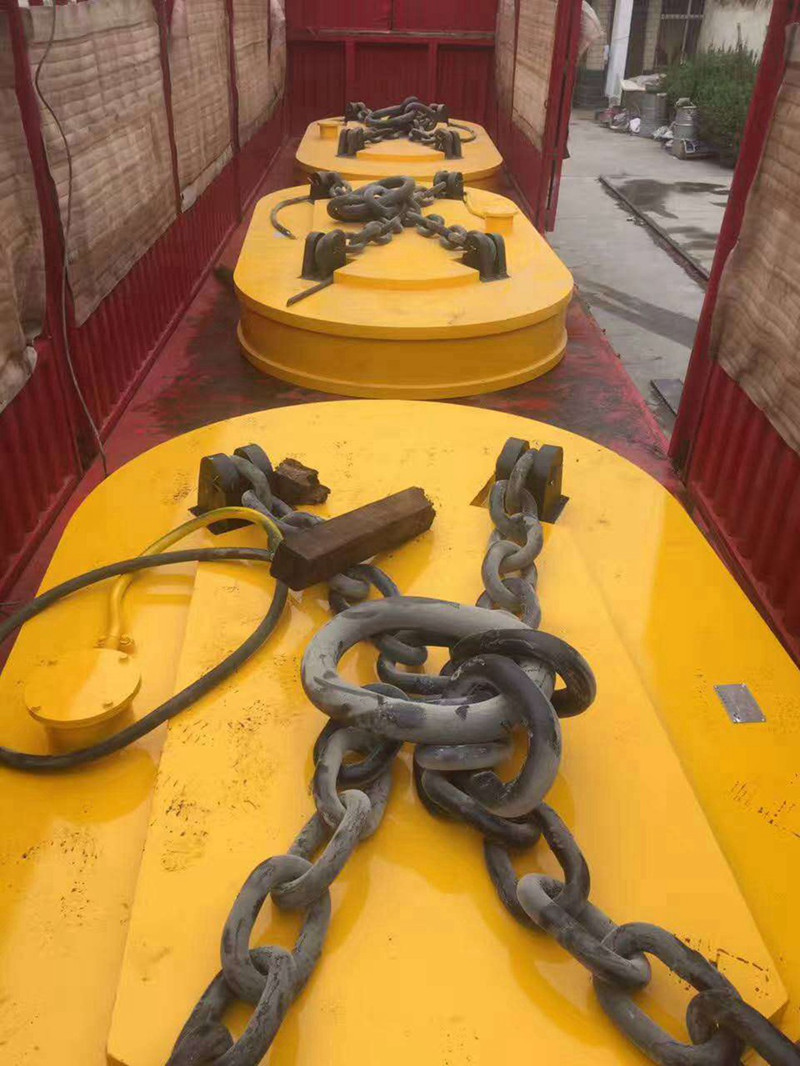

Scrap Yard Metal Magnet are matched with various cranes to provide ideal material handling solutions for steel, shipbuilding, heavy machinery, steel warehouses, ports, railways, etc. At the same time, we can provide different shapes of crane electromagnet to meet the handling of different materials, such as round shaped, oval and square crane electromagnet.

1. Lifting electromagnet adopts a special magnetic circuit structure, the magnetic field is strong, the magnetic pole is distributed reasonably, and the magnetic material can be hoisted safely and reliably.

2. Adopt the excellent electromagnetic wire production, reduce the current density of the product, effectively control the heating and temperature rise of the product, thus improving the performance of the product.

3. High temperature products adopt multi-layer insulation structure and use high quality insulation materials to effectively prevent the heat from being absorbed into the coil.

4. Adopt vacuum glue craft, filling material can fully penetrate into the coil, the coil and iron core, clock cover shell to form a whole, the heat generated by the coil can send out, can improve the insulation performance of the product and heat conduction performance.

5. in order to prevent the magnetic material from working in the high temperature environment, the welding of magnetic materials and non-magnetic materials is cracked and special materials are used for special processing. Ensure product quality.

Scrap Magnet Manufacturering Process

Iron Core Selection: Q235A material with the best magnetic permeability is chosen for the iron core.

Coil Generation: Coils are wound using high-quality materials, either aluminum or copper, ensuring sufficient winding for optimal magnetic force.

Magnet Shell Construction: The magnet shell is made from Q345B steel plate material. It undergoes tight welding and surface rust removal processes to enhance durability.

Insulation Treatment: Insulation materials are added and a thorough insulation treatment is applied. Oven dehumidification is utilized to remove moisture, improving insulation performance and preventing short circuits between coils.

Bottom Cover Welding: The bottom cover, made from 20Mn23L material, is welded to ensure the magnet's strength and prevent deformation when in use.

Rust Prevention and Painting: The magnet shell undergoes derusting and painting processes to maintain its adhesion, ensuring the paint sticks securely to the suction cup.