Single beam workshop cranes are often the most cost-effective lifting solution for various applications and industries. Single girder cranes use less material and are more compact and lightweight than a double girder crane, which results in a significant cost-savings in material, freight, and installation. Also, because single beam workshop cranes only require one bridge beam, these systems typically have less deadweight, meaning they can utilize lighter runway systems and tie into the existing building support structure.

Sinoko Rich Industrial Experiences

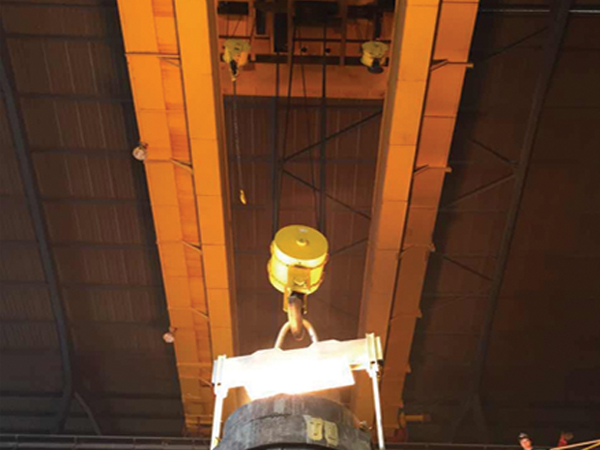

Sinoko Cranes have rich experience and good at fully automatic intelligent cranes, metallurigical cranes, explosion-proof cranes, and other special cranes, we can provide you with various optional functions according to the special lifting needs in your industry, such as electronic anti-sway, remote monitoring, lifting synchronization and other functions. These are just a part of them.

|  |

| Steel Industry | Paper Making |

|  |

| Energy Recycling Crane | Petrochemical Crane |

|  |

| Vehicle Manufacturing Crane | Airocrafe Crane |

Types of Cranes for Different Working Conditions

Single girder bridge crane is mainly divided into Traditional (LDA type)electric single girder overhead crane, European Single Girder Overhead Crane, Low Headroom Single Girder Overhead Crane, Explosion-proof Single Girder Overhead Cranen, Freestanding Workstation Bridge Cranes,Underhung Monorail Cranes, LDP electric single beam overhead crane and so on. If the workshop clearance height is limited, the top running type overhead crane (LDP electric single beam overhead crane) is recommended to save the above clearance space and below lifting.

|  |

| European Single Girder Overhead Crane | |

|  |

| Low Headroom Single Girder Overhead Crane | Explosion-proof Single Girder Overhead Crane |

|  |

| Freestanding Workstation Bridge Cranes | Underhung Monorail Cranes |

Customer Projects And Cases

Sinoko single girder overhead cranes produced have been exported to many countries and regions in the world, such as 3 ton Underhung Monorail Cranes in Dhaka of Bangladesh, 5 ton electric chain crane in Karachi of Pakistan, 10 ton overhead crane in Australian, 2 ton LDA bridge crane in Pakistan. We provide installation and commissioning of equipment to help our customers get up and running quickly.

|  |

|  |

European design single beam workshop crane is mainly composed of main bridge, electric hoist, crane traveling mechanism, electrical control system and other components. Including the following advanced and reliable features:

Unique structure, higher lifting space.

European design, light dead weight.

PLC+human-computer interaction, comprehension protection.

Protectio class IP55, F class insulation.

Flat cable+traveling C channel, smoothly traveling.

High performance and easy operation.

Low cost of running and maintaining.