Warehouse cranes system plays a central role in improving your work efficiency and productivity.

Warehouse cranes type: warehouse overhead crane, warehouse mobile gantry crane, warehouse jib crane, workstation cranes;

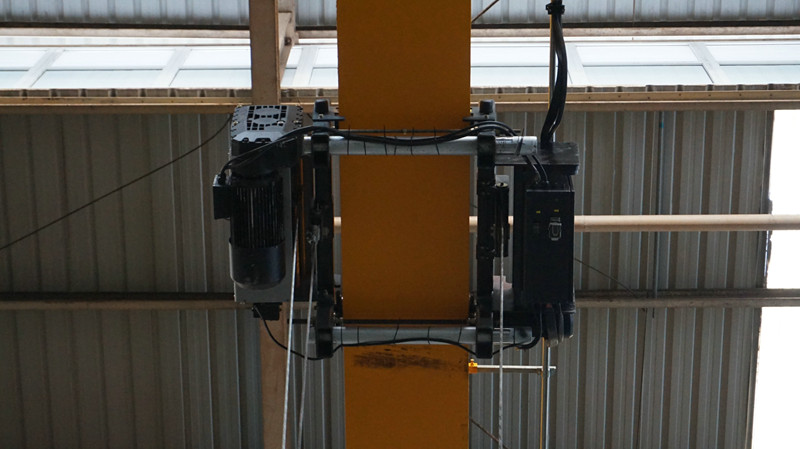

Warehouse overhead crane is installed on the track of the fixed span of the building, consists of bridge frame, cart running mechanism, lifting trolley (with lifting mechanism and trolley traveling mechanism), electrical equipment, etc. There are different types of overhead cranes for you to choose from, including single girder crane, double girder crane, top running crane and underhung crane.

Warehouse mobile gantry crane is manufactured for lifting equipment, loading and unloading of the warehouse, maintaining heavy-duty equipment and transporting materials, applicable for small and medium factory. The best advantage of the crane is Omni-directional movability, fast to assembly, small volume, can be moved to another are only with a minibar.

Warehouse jib cranes is a new generation of light hoisting equipment made for modern production, which is suitable for high-reliability electric chain hoistsSinoko jib cranes are suitable for almost any kind of workstation.

Workstation cranes can be flexible manual, semi-automatic or automatic operation according to the working conditions. Sinokocrane make it free standing crane modular design, the standard profiles are bolted together, easy to installation & transportation.

Compact overall size, Low clearance height, Small wheel load makes warehouse crane can save factory space and investment cost

Advanced technology and excellent professional knowledge makes Sinoko warehouse crane outstanding in the same kinds of hoisting products.

Perfect after-sale service and Rich expertise guidance free you from material handling troubles.

Competitive price and excellent quality makes Sinoko warehouse crane your optimal choice.

There are two distinct control forms supplied for the Warehouse crane , one is ground control with a rope handle, another is the remote control. A customized warehouse crane also would be produced by our company on the basis of clear requirements.