European single-girder 7 ton overhead crane consists of hoisting mechanism (wire rope electric hoist and other structures), main beam, end beam, electric control system, etc. European crane has low height, small size, light weight, small wheel pressure and humanity.

This design and many other advantages are a new generation of innovative products, superior performance, compact structure, small net space size, and full use of the factory's effective space.

The main components of the 7 ton overhead travelling crane include the main girder, electric hoist, traveling mechanism, and control system. These components work together seamlessly to ensure smooth and efficient operation.

| Main beam | The main beam adopts box-type structure and connects with end beams by high-strength bolt ensuring easy transportation. The professional processing equipment ensure the connection accuracy of main beam and end beam, making crane run steadily. |

| End beam | End beams are the rectangular steel pipe and welding molding in a CNC machine tool positioning processing; each end beam is equipped with a double wheel rim wheel group, buffer and anti-derailment protection device. |

| Hoist | Ø Maximum space using Ø Precise operation Ø Low maintenance cost Ø Less fault downtime Ø Minimum hook limit space & distance Ø Standard world-renowned brands: SEW, ABM three in one type motor, Schneider electric parts |

| Drum, Steel wire rope, Rope guide | Ø The drum is made from high-quality seamless pipes and processed by numeral control CNC machine, after finish machining, the rope groove on drum works coordinately with rope guide to efficiently prevent rope loose and tangling. Ø Steel wire rope adopts high strength 2160N/mm2imported wire rope, which has super safety performance and longer service life Ø Standard rope guide is processed from engineering plastics, with strong abrasion resistance and good self-lubricating performance. |

| Lifting mechanism gear box | Shell of reduce uses aluminum alloy material, with light weight and corrosion resistance. Semi-grease lubricant in full sealed box gets all gears lubricated fully and should not be changed within the design circle for safety service. Each gear which gets the process of surface hardening and high-precision grinding ensures stable running of gear box. Ø Small size and light weight Ø Running smoothly and steadily, low noise Ø Corrosion resistance and maintenance-free |

| Lifting mechanism brake | The hoisting mechanism motor equipped with double-disc electromagnetic brake. According to the safety regulations, SINOKO CRANE adopts the braking force of the brake higher than 1.8 times of the rated torque. Ø Fast movement and high reliability Ø Maintenance-free and self-regulated Ø Dustproof design and longer service life |

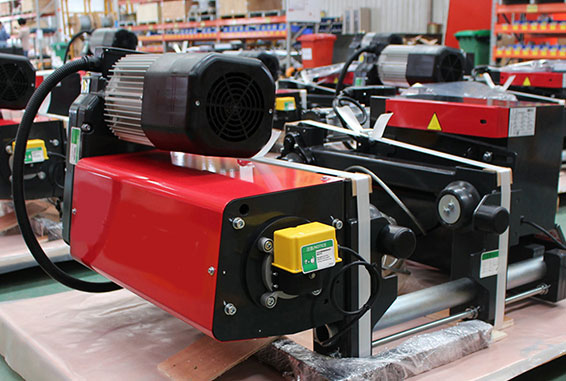

| ABM three in one type drive | Drive mechanism is sealed three in one type. Ø Self- lubricating Ø Maintenance free Ø Inverter control Ø Stable running Ø Reliable quality Ø Low noise |

| Hoist cable dragging system | Ø Consisting of flexible flat cable, C-shaped steel slide Ø Flat cable with good flexibility Ø Aerial socket connecting, one to one correspondence,convenience of connection Ø Maintenance free,long operating life. |