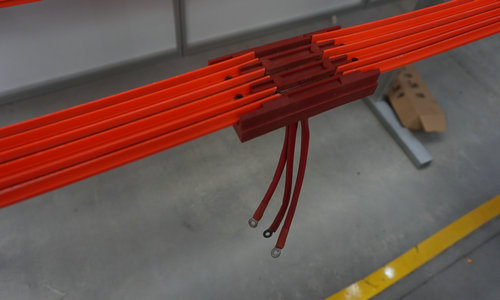

Seamless crane conductor bus bar can be used for electric hoist, electric beam and electric single girder bridge crane; stacker, automatic detection line for electromechanical products, automated production line, mobile power tools and other mobile power receiving equipment, as well as factories, mines, workshops. At present, the H class safety bus bar is generally used, which has great improvement in protection level and insulation, and is safe and reliable.

1. It is easy for installation and daily maintenance with combined design, especially suitable for working at heights.

2. It has long service life and unique conductor jacket design, which greatly extends the service life of the bus bar system.

3. It is safe and reliable, that is, there is no danger of electric shock when using finger contact, and it complies with IP23 standard.