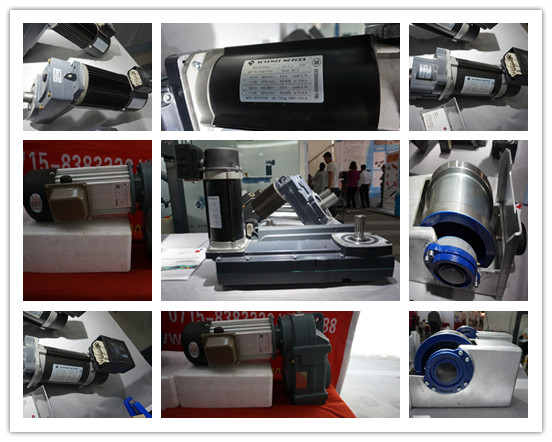

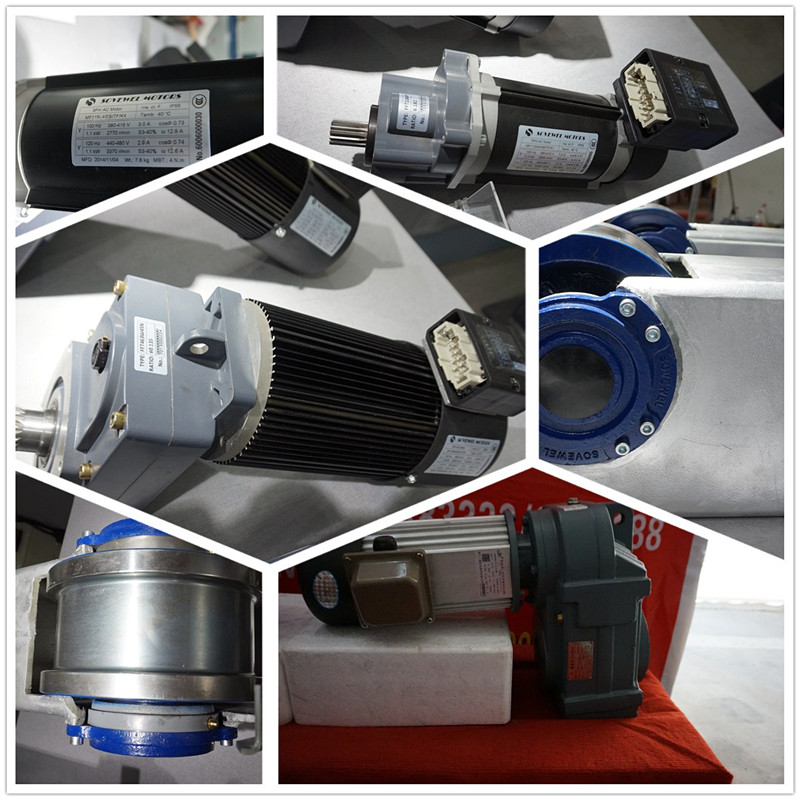

There in One Gear Motor Driving System Structures and Scope of Supply:

1. The reducer consists of gears, axles, domestic bearings, box shells, bolts and pads.

2. The motor is composed of stator, bearing, rotor, shell, brake, heavy load connector (aviation plug).

3. The brake is divided into electromagnetic brake and side magnetic brake.

Self-Developed There in One Driving System Features from Sinokocranes:

1. The surface is chemically treated with strong corrosion resistance.

2. The unique electromagnetic design reduces the shaft current and improves the service life of the bearing.

3. 5-120HZ continuously variable transmission, low speed operation torque is smooth, no crawling phenomenon.

4. The high heat resistant composite enamel round copper wire has reliable winding performance and long service life.

5. The use of high-performance brakes, life can reach 1 million 500 thousand times.

6. Import bearings with international brands to ensure service life.

7. Standard thermistor and heat protection.

8. Standard heavy duty connector plug, quick connection, high safety.

9. Ambient temperature -15 ~ +40 C

10. Relative humidity 90%

11. Working system S3-40%

12. Insulation grade F/H

13. Protection level IP55

14. Three phase AC power supply