Mold load turning device is designed for safe lifting and turning of inherent loads with nearly round or square cross -section. Especially suitable for heavy and bulky goods, such as machine components, welded frames, mould boxes for foundries, concrete precast parts

Features

Mold load turning device increases operational safety and productivity. Auto load balance system is to adjust synchronously and asynchronously. The max. carrying capacity is up to 130 ton.

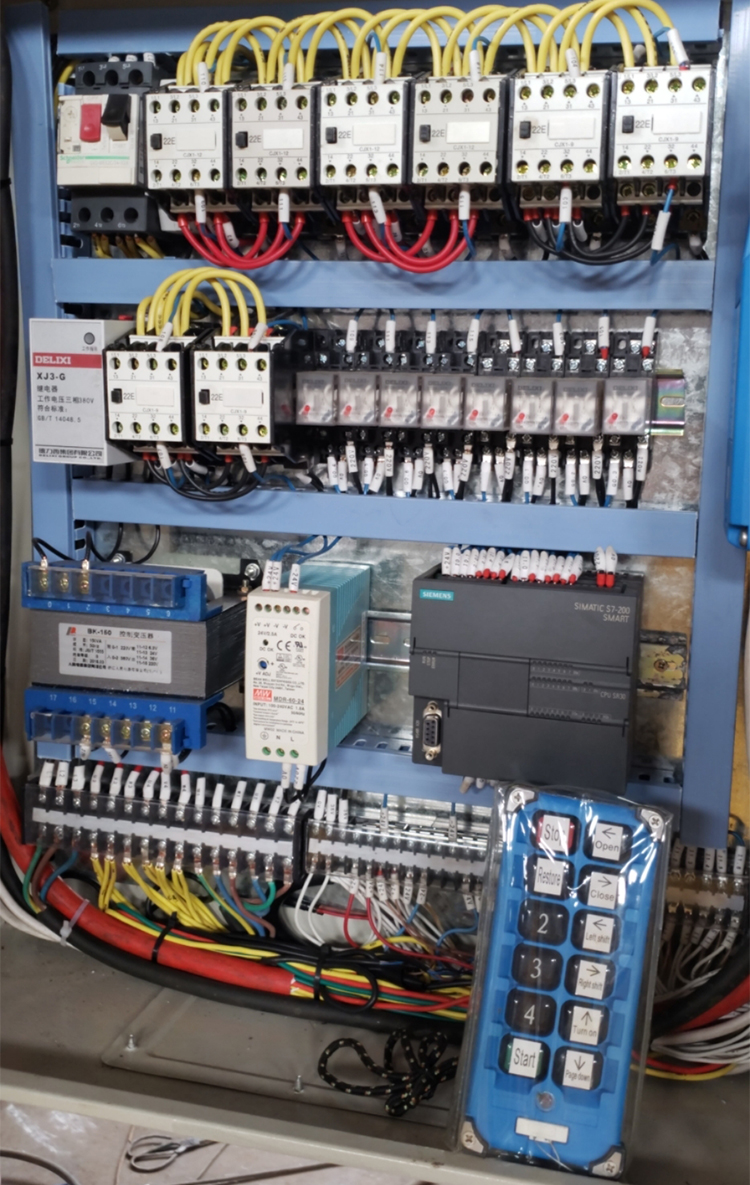

Electric Panel of Mold Load Turning Device

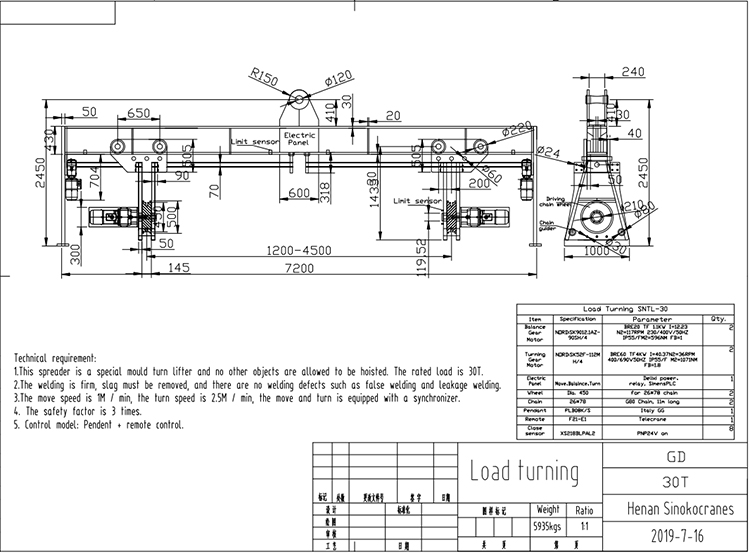

Sketch of Mold Load Turning Device

Specification

1. | Suspension Frame | It is suitable for single crane hooks according to DIN15401 |

2. | Safe Turning Equipment | The overturning procedure can be stopped at any time and in each position by emergency stop |

3. | Driving Adjustment System | Two roller are driven by an electric motor, and available to run in synchronism. |

4. | Emergency Stop Operation | Radio remote control with automatic belt or chain cut-off to prevent the belt lock from driving through the rollers |

5. | Electric Panel Control with PLC | The electric panel control is completely wired in the switch box and with plug for the connection to the crane facilities without spring cable reels. |

FAQs

A Mold Load Turning Device is specialized lifting equipment designed to safely flip heavy, bulky items—like molds, machine components, or concrete precast parts—across industries such as foundries, mold processing, automotive, steel mills, and ports.

The device features a robust auto load balance system capable of handling loads up to 130 metric tons, with synchronous and asynchronous adjustment options available.

It uses an electric-driven dual-roller mechanism for synchronized turning, includes an emergency stop function to halt operations at any point, and supports remote operation via radio remote control with automatic belt or chain cut-off for added safety.

The Mold Load Turning Device includes a fully wired PLC-controlled electric panel housed in a switchbox, equipped with plug-and-play connections designed for easy interface with existing crane infrastructure—with no need for spring cable reels.

Beyond the emergency stop and automatic cut-off, the design also incorporates a sturdy suspension frame tailored for single crane hooks (meeting DIN15401 standards) and synchronized roller control for smooth, secure load handling.

By automating load overturning and offering precise control—including stopping at any angle—it significantly boosts operational safety and efficiency for handling heavy, awkwardly shaped loads in industrial environments.