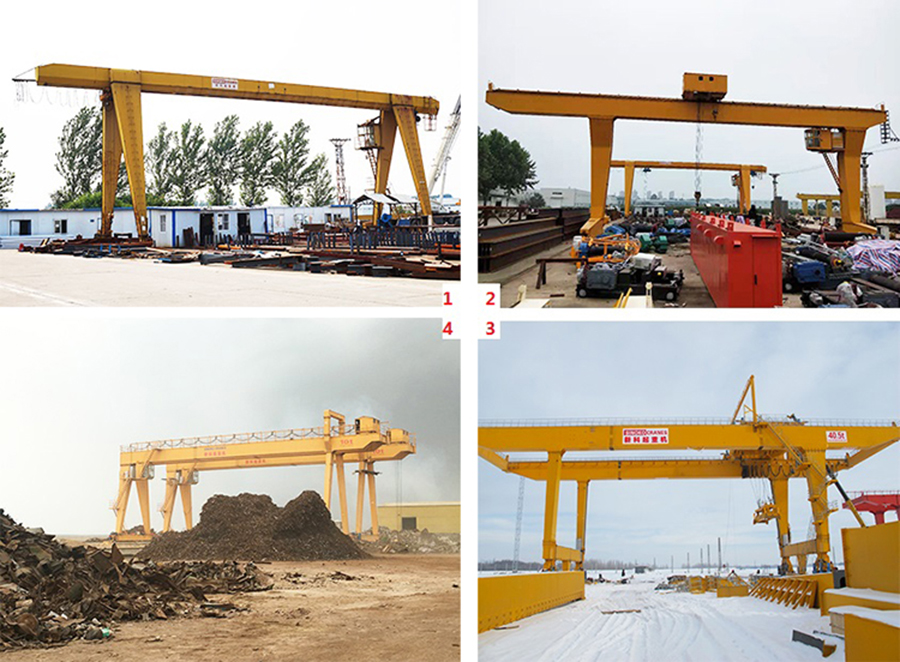

I. Brief Introduction of RTG Type Rubber Tyred Mobile Gantry Crane

Sinokocranes RTG type rubber tyred mobile gantry crane is used to lift or handle materials in various applications, such as port yard, outdoor storage and indoor warehouses.

II. Description of RTG Type Rubber Tyred Mobile Gantry Crane

The RTG crane has a steel structure with high rigidity and stability that allows the materials to be handled in a very precise way and without shaking in their movement, even at high handling speeds. The mobile gantry crane is powered by diesel generator systems or other power supply equipment, which is an excellent solution for medium-sized material handling.

III. Features of RTG Type Rubber Tyred Mobile Gantry Crane

Sinoko Crane brand RTG type rubber tyred mobile gantry crane is designed based on DIN15018, and welding for DIN18800, the level upto DIN8563.

# | Mechanism Name | Function and Advantage |

1 | Hoisting | Heavy duty motor, 60% ED rating Super drum, longer rope lifetime DIN 34CrMo4 hook, Class T |

2 | Cross Travelling | 3 in 1 gear motor with hardened gear, H Insulation high protection level Stepless speed control |

3 | Long Travelling | Non-coupling transmission Modular design Smart size |

4 | Free Turning | PLC control system Rubber tyred wheel Free turning |

IV.Other series of gantry cranes from Sinoko Crane factory:

1. MH type single girder Electric hoist gantry crane

2. L type single girder gantry crane

3. MG type general purpose double girder gantry crane

4. Container lifting double girder gantry crane