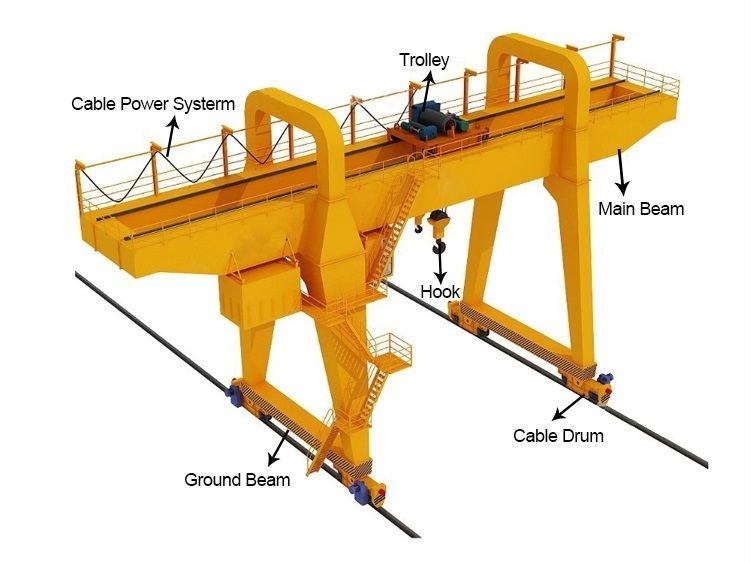

Gantry crane (also known as goliath crane) is supported on the ground track by two legs of the bridge. In the structure by the door frame, cart operation mechanism, lifting trolley and electrical components. Gantry crane door frame part of the bridge (including the main beam and end beam), legs, beams and other parts of the lower beam. In order to expand the scope of crane operation, the main beam can extend beyond the supporting legs to one side or both sides to form cantilever.

1.Double box beam with steel legs moving through the ground beam as cranetravelling system

2.The camber of main beam will be designed as Span*1-1.4/1000.

3.Steel Material: Q235 or Q345

4.Shot-blasting Sa2.5 for main girder and supporting beam

5.Epoxy zinc rich high quality painting.

6.Electrification and outfitting

7.Brand: CHINT, SIEMENS ,Schneider

8.Conductor power supply: Cable Reel or bus bar.

9.Frequency conversion, double speed, single speed, and all hoist and crane movements are independent and can be run simultaneously different design due to meet crane applications

10.Whole layout provides good protection against special working environment. Such as gas workshop, plants, warehouses etc.