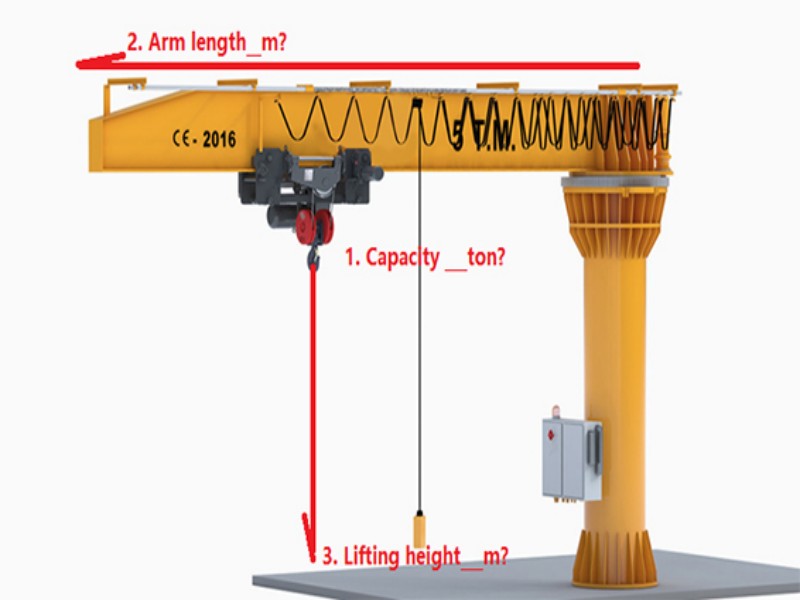

Pillar mounted jib crane is a small lifting equipment developed in recent years. Rated lifting capacity is 0.125~10T. pillar crane structure is unique, safe and reliable, with high efficiency, saving energy , saving time, saving effort and flexible features. And can take actions randomly in a three dimensional space, especially in short, intensive lifting occasions more shows than any other conventional lifting equipment unique advantages, widely used in workshops, warehouses, terminals and other fixed places.

Features

The pillar jib crane has the advantages of novel structure, reasonable, simple, convenient operation, large working space, etc. It is an energy-saving and high-efficiency material lifting equipment.

1. Compact structure: Easy to improve efficiency in narrow working area.

2. Wide rotating angle: Free to rotate from 90-360 degree, special designed rolled bearing to achieve smooth travel with low noise.

3. Cooper motor: Copper coil motor with strong drive, long service life and heavy duty.

4. Stable pillar bottom: To be fastened with Class 8.8 strong tensile bolt, more durable and safe working

Specification

| Model | Capacity (kg) | Arm Length (mm) | Lifting height (mm) | Ground pit size (mm) | Bottom plate size (mm) |

| SJB-0.5 | 500kg | 3000-6000 | 215-315 | 1000*1000*800 1200*1200*900 | 850*850*25*8 1000*1000*30*12 |

| SJB-1 | 1000kg | 3000-6000 | 265-415 | 1400*1400*1100 1800*1800*1200 | 850*850*25*8 1000*1000*30*12 |

| SJB-2 | 2000kg | 3000-6000 | 315-515 | 1600*1600*1200 2000*2000*1400 | Non-advice |

| SJB-3 | 3000kg | 3000-6000 | 315-515 | 1600*1600*1200 2000*2000*1400 | Non-advice |

| SJB-5 | 5000kg | 3000-6000 | 415-515 | 1600*1600*1200 2000*2000*1400 | Non-advice |

CASE

From concept to installation, our cranes are trusted in diverse projects around the world. Explore case studies that showcase reliable solutions and real-world results..

3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteInstallation of 3T Portable Gantry Crane for Thai Manufacturing Facility

The 3 ton portable small gantry crane specially designed by Sinokocranes for Thai customers has significantly reduced the production costs for the customers and enhanced their production efficiency.

Learn More Get a QuotePakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteFAQs

A: This crane—also called a floor‑mounted or free‑standing jib crane—is composed of a vertical column, slewing arm, and electric hoist running on a cantilever I‑beam. Designed for compact, repetitive lifting tasks, it’s ideal for crowded workshops, warehouses, and fixed workstations.

A: Sinoko offers models ranging from 125 kg to 10,000 kg (0.125–10 t) capacity. Arm lengths typically span 3,000–6,000 mm, with customized configurations available upon request.

A: These jib cranes rotate smoothly through 90–360 degrees, courtesy of specially designed rolled bearings that minimize noise and ensure reliable slewing performance.

A: They feature compact yet robust structure—bolted to reinforced concrete—and include copper‑coil motors for durability, Class 8.8 tensile anchor bolts for stability, and optional slewing gear. All factors combine to deliver safe, efficient lifting.

A: The SJB‑2 model handles 2,000 kg, has an arm length of 3,000–6,000 mm, lifting height of 315–515 mm, and requires a foundation pit sized approximately 1,600 × 1,600 × 1,200 mm.

A: These cranes typically include pendant control for ground-level operation. For advanced setups, optional features include infinite 360° slewing via slip‑rings, electric slewing gear, electric trolley travel, and remote control functionality.