Overview:

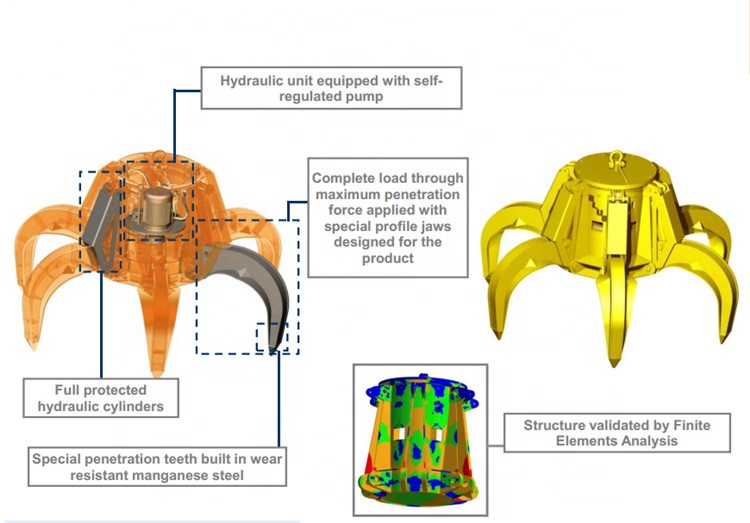

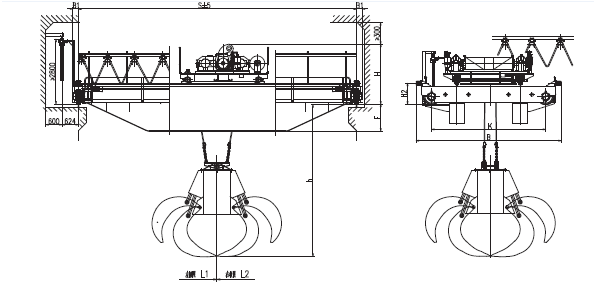

Electro Hydraulic Orange Peel Grab, the center of gravity is lower, and the connecting wire rope between the crane and the grab is made into a four-point 'V'-shaped arrangement, which reduces the twist when the grab is used and the collision between the grab and the buildings. The grab bucket and the wire rope are connected by a transition chain. An angle sensor device is installed in the electro hydraulic orange peel grab to detect the tilt of the hydraulic grab and prevent the grab from tipping. The power supply voltage of the multi-petals hydraulic grab is 380/415/440V. The closing of the grab is completed by a motor driven oil pump. The control system transmits the control room through the cable on the cable drum. It is controlled by a set of its own control buttons to facilitate personnel control.

The hydraulic center of the hydraulic grab uses imported ABB motors, the protection level is IP66, the bucket body uses Q345-B steel materials, and the bucket teeth use high-strength wear-resistant material Hardox 500, which ensures the service life of the grab.

Main Features

1) Simple structure ,easy in installation and maintain.

2) Adopting advanced world famous brand components in electric parts and operation parts.

3) with the great abrasive resistance, high strength and can grab the material very well.

4) Running in a high authorization and internationalization,no pollution

5) Widely used in Wharf, steel mills, power plants, ships, etc.

| Type | Electro Hydralic Orange Peel Grab |

| Capacity | 1 CBM TO 20 CBM |

| Grab Structure | Q345B |

| Pins &Axles | 40 Cr1Mo 28,IS;1570,Hardened,ground and tempered and Hard Chromium Plated |

| Working Pressure | Opening pressure 140 bar Closing pressure 220 bar |

| Grab Working Cycle | Opening 10 to 15 seconds |

| Closing | 13 seconds |

FAQs

An Electro-Hydraulic Orange Peel Grab is a heavy-duty lifting device used for handling bulk materials like scrap metal, coal, and rocks.

It uses hydraulic power to operate multiple steel claws that grab and lift materials securely, ideal for both ship loading and unloading.

It’s primarily used in ports, scrap yards, and construction sites for handling bulk materials such as scrap steel, coal, and ores.

Our orange peel grabs come in various sizes, with capacities ranging from 1 ton to over 20 tons, based on your needs.

Yes, Sinoko offers customizable grabs tailored to specific material handling requirements and environmental conditions.