Clamshell Bucket Types

Mechanical Clamshell Bucket: A mechanical clamshell bucket is operated manually using mechanical linkages and levers. It is commonly used for smaller-scale material handling applications where precise control is not a primary requirement. This type of bucket is often found in smaller cranes or excavators.

Hydraulic Clamshell Bucket: A hydraulic clamshell bucket is powered by a hydraulic system, providing precise control and efficient operation. It is suitable for larger-scale material handling tasks that require accurate grabbing, lifting, and releasing of materials. The hydraulic system allows for smooth and controlled movements, improving productivity and reducing operator fatigue.

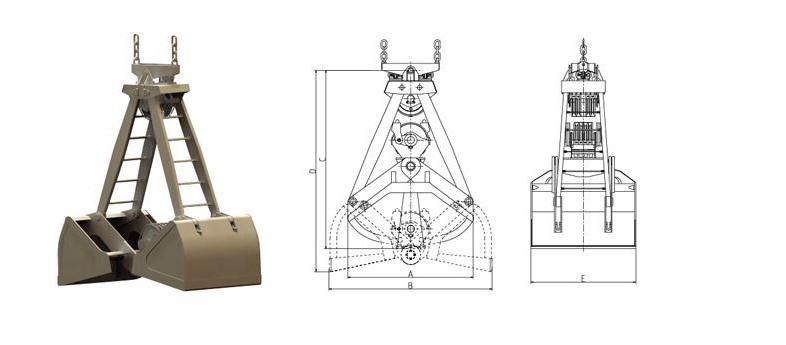

Electro-Hydraulic Clamshell Bucket: An electro-hydraulic clamshell bucket combines electrical and hydraulic components for operation. It utilizes an electrical control system to operate the hydraulic functions, offering enhanced control and automation capabilities. This type of clamshell bucket is commonly used in larger cranes and material handling applications where advanced control features are necessary.

Radio-Controlled Clamshell Bucket: A radio-controlled clamshell bucket is operated remotely using radio-frequency technology. It allows the operator to control the bucket's movements from a distance, providing increased safety and flexibility. This type of bucket is useful in hazardous or hard-to-reach areas where manual operation may be challenging.

Grab Bucket with Clamshell Mechanism: A grab bucket with a clamshell mechanism combines the features of a grab bucket and a clamshell bucket. It is equipped with a set of jaws or tines that can open and close like a grab, allowing for versatile material handling capabilities. This type of bucket is commonly used in applications where both grabbing and scooping functions are required, such as bulk cargo handling in ports.

Clamshell Bucket Feature

1. Grab Advantages: Simple structure, good performance, high productivity.

3. Supplied with removable spill plates, giving the capability to work light and heavy cargos with the one grab.

4. Radio remote control unit gives facility to start or stop the grab with one button. Radio control unit will operate from 100 m distance from the grab.

5. Work with oil circulation and battery.

Clamshell Bucket Specification

Models | U01~U110 |

Volumes | 3-20m³ |

Type | light, middle, heavy |

The proportion of materials | as per yours |

Capturing the materials | 0.5---11t |

Percentage of pulley | 36 |

The diameter of steel wires | 14--28 mm |

The diameter of pulley | 350--700 mm |

Time of opening and closing | 8--18 s |

Self-weight of grab | 2--11 t |

Tons of the match hoist crane | 5--20 t |

Total height of grab | as per grab size |

Notes | Design as customer's demand |

At Sinokocranes, we specialize in providing high-quality attachments for cranes. Our Clamshell Bucket for Crane is designed to meet the demanding requirements of various industries. Choose Sinokocranes for exceptional performance, durability, and excellent customer service.

FAQs

Clamshell bucket is mainly used for handling bulk materials such as sand, gravel, grain, coal, and minerals. It is widely applied in ports, warehouses, and construction sites for loading, unloading, and stockpiling operations.

Clamshell buckets are attached to cranes via hooks or specialized lifting attachments. They open and close using mechanical or hydraulic systems to grab and release materials efficiently.

The steel structure of our products is generally packaged with plastic film to protect it from rain.

Electrical and other smaller parts are packed in standard export-use non-fumigation wooden boxes or plywood boxes, and are reinforced with iron nails or steel plates to prevent damage in collisions.

Our clamshell buckets have capacities ranging from 0.5 cubic meters up to 30 cubic meters, customized according to your material density, crane capacity, and operational requirements.

Yes, we provide specialized underwater clamshell dredging buckets designed for river, port, and seabed dredging operations with durable and corrosion-resistant structures.

You should consider your crane type (single rope, double rope, four rope, or hydraulic), lifting capacity, material type and density, working environment, and operational frequency. Our engineers can assist you in making the best choice.

Related Grab Buckets

Discover more crane grab buckets to meet various application needs and improve your working efficiency.

Excavator Orange Peel Grapple

Enhance your excavator's material handling capabilities with the Excavator Orange Peel Grapple. With its unique orange peel configuration and seamless integration, this grapple offers efficient and precise handling of bulk materials. Choose Sinokocranes f

Learn More Get a QuoteHydraulic Grab Bucket

With its robust construction, hydraulic control system, and high gripping strength, this grab bucket ensures optimal performance and productivity. Choose Sino

Learn More Get a QuoteScrap Handling Grabs

Scrap handling grab bucket is applicable to harsh environment and engaged in handling iron scrap or larger block materials in steel plant. Get free solutions

Learn More Get a Quote