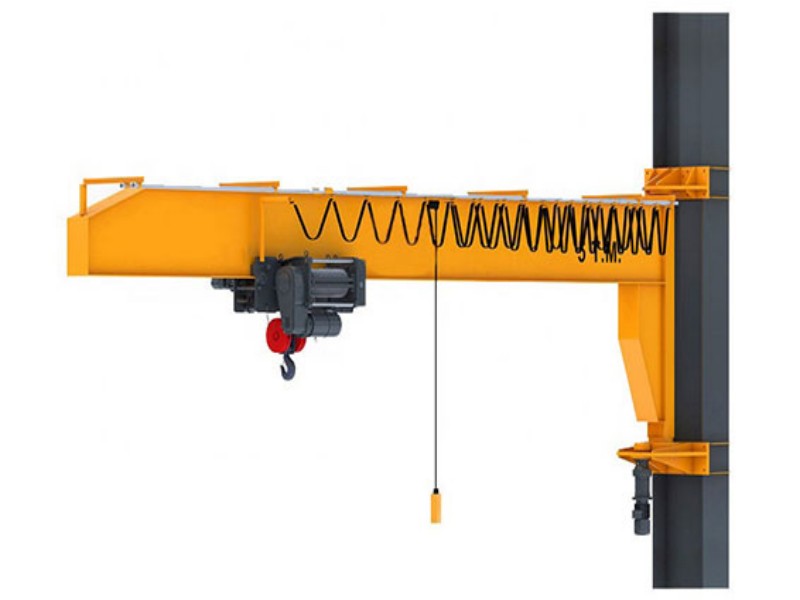

Pillar jib crane is a kind of middle and small lifting and equipment developed recently and very suitable for short distance moving and workplace of crowed lift and transportations. Free standing jib cranes are designed to stand on the land not by any other support but by themselves. It consists of a pivoting vertical column and a horizontal load supporting boom. We rely on not low jib cranes price but the high quality of free standing jib cranes to win to achieve the growing of our company.

Environmental conditions of floor mounted jib crane:

1.The power of the crane is three-phase AC, rated frequency of 50HZ, rated voltage of 380V.

2.The altitude of the crane installation site is less than 2000m.

3. Inflammable, explosive and corrosive gases are forbidden in the installation site of the crane.

4. The crane is not allowed to lift the molten metal, toxic and inflammable and explosive materials.

Floor Mounted Jib Crane Features

Pillar is made of sturdy, hollow steel sections

Jib arm is made of I-beam or weld steel box, depends on capacity and duty group.

Bolted end connection plate for rapid mounting

Safety anchoring with ribbed pillar base

Low-build profile section jib arm for optimized hook height

Power supply via slip-rings for infinite 360 degree slewing.

Complete with electrical systems including lockable mains switch and power supply to the hoist

Electrical equipment with class F insulation, protection type IP 54

Operated from floor level via pendant controls

Working with CD/MD electric hoist or chain hoist

Low headroom offers optimal highest hook position

Optional electric slewing gear

Optional electric hoist travel

Optional mobile control (standard with wire rope hoists)

Floor Mounted Jib Crane Specification

Item Code | Rated Capacity | Lifting Speed | Arm Length | Max. Slewing radius | mini Slewing radius | lifting height | total height |

KGS | high/low | mm | mm | mm | mm | mm | |

BZ0.25t-5m | 250 | 8/2 | 5200 | 5000 | 900 | 3000 | 3740 |

BZ0.5t-m5 | 500 | 4/1 | 5200 | 5000 | 950 | 3000 | 3870 |

BZ1t-5m | 1000 | 8/2 | 5200 | 5000 | 1050 | 3000 | 4050 |

BZ2t-5m | 2000 | 4/1 | 5200 | 5000 | 1300 | 3000 | 4210 |

BZ3t-5m | 3000 | 8 | 5300 | 5000 | 1600 | 3000 | 4690 |

BZ5t-5m | 5000 | 8 | 5300 | 5000 | 1700 | 3000 | 4960 |

FAQs

Floor mounted jib crane is used for lifting and moving materials within a circular working area. It is ideal for workstations, machine shops, assembly lines, and loading/unloading operations.

Clamshell buckets are attached to cranes via hooks or specialized lifting attachments. They open and close using mechanical or hydraulic systems to grab and release materials efficiently.

Floor mounted jib cranes typically offer a rotation range up to 360 degrees, providing flexible material handling coverage within the work area.

It is installed by anchoring the base plate to a reinforced concrete foundation to ensure stability and safety during operation.

es, with proper weatherproofing and anti-corrosion treatments, floor mounted jib cranes can be used for outdoor applications such as loading yards and docks.

Consider your required lifting capacity, boom length, rotation angle, lifting height, and installation environment. Contact our engineers for professional selection guidance tailored to your project.

More Jib Crane Options

We offer pillar jib cranes, wall-mounted jib cranes, and electric hoists to improve your lifting efficiency.

Wall Mounted Arm Slewing Jib Crane Price

Wall Mounted Arm Slewing Jib Crane Price structure is unique, safe and reliable, with high efficiency, saving energy , saving time, saving effort and flexible features. Widely used in workshops, warehouses, terminals and other fixed places.

Learn More Get a QuoteLow Clearance Wire Rope Electric Hoist 10 Ton

European type 10 ton wire rope hoist uses advanced European tech with SEW/ABM motors for high quality performance. Contact us now for a free quote!

Learn More Get a Quote3 ton Electric Chain Hoist

The 3 ton electric chain hoist has a high working level, good safety performance, high reliability, low failure rate, the chain runs in the sprocket, Get free quote.

Learn More Get a Quote