CXTD type Single Girder Bridge Crane is European Model Bridge Crane equipped with SIC brand Wirope Electric Hoist. With Advanced technology, Our European Model Single Girder Bridge Crane could be made from 5 ton,10 ton,15 ton to 20 ton. Smoothly Traveling with inverter Control make sure the Crane more durable, stable operation,low noise and maintenance free.

Technology Advantage of European Model Single Beam Overhead Bridge Crane:

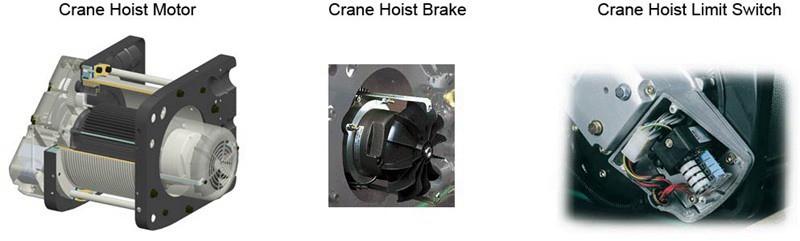

Compact Structure: Lifting motor,reducer,cable drum and lifting limit switch are modified as compact integrated structure design, saving the crane space a lot. The modular design not only enhance the mechanism reliability, but also reduce the maintenance time and cost. All hoisting mechanism design are following FEM standard.

Key Production Process Control of European Type Roof Traveling Bridge Crane:

Welding process: We perform special process control procedures, control strictly in terms of the operating environment, consumables selection, training, and other special operations. The major welds used automatic submerged arc welding process to ensure weld quality and test report issued.

Main girder production: We have three main girder production lines, use automatic hydraulic pressure of the main girder assembly machine Group, to ensure the main girder of the technical requirements. And we use double-sided automatic submerged arc welding process, to ensure the realization Pre-camber.

Crane assembly: We have three assembly lines crane bridge, through the process of process control, machine to achieve quality assurance; through the process flow control, ensure the whole machine quality.

Electrical equipment parts: All wiring of the components in the electric control box have been completed and pre-commissioning by power on test and loading test. Meanwhile, all the wiring are marked by line number ,no falling off; Each line of the sequence is very clear and easy to repair in the future. All external connections of electric control box adopt aviation fast plug, which has the feature in easy plugging, high protection class and long service time; also prevents from electric leakage, shock and other security incidents.

Specification

lifting capacity(T) | 1,2,3,5,10T | 16,20T | |||||

Span(M) | 7.5-31.5M | ||||||

Crane travelling mechanism | Travelling speed(m/min) | 20/30 | 20/30 | ||||

Motor | Model | ZDY21-4 | ZDY21-4 | ZDY122-4 | ZDY131S-4 | ZDY112L1-4 | |

Power(kw) | 2/0.8 | 2/1.5 | 1.5/2 | 2.2/2 | 2.2/2 | ||

Rotation (m/min) | 1380 | 1380 | |||||

Lifting mechanism | Electric hoist model | CD1/MD1 | MD1/HC | ||||

(electric hoist)&electric hoist travelling mechanism | Lifting speed (m/min) | 8,8/0.8 7,7/0.7 | 3.5 3.5/0.35 | ||||

Lifting height (m) | 6 ,9 ,12, 18, 24, 30 | 12,18,24,30 | |||||

Travelling speed (m/min) | 20(30) | 20(30) | |||||

Motor | Taper Squirrel-cage type | Taper Squirrel-cage type | |||||

Work duty | A3-A5 | ||||||

Power supply | 380V 50HZ three phase | ||||||

Wheel diameter | 270mm | 370mm | |||||

Treadof trail | 37-70mm | 37-70mm | |||||

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

An overhead crane, also known as a bridge crane, is a type of crane that runs along a horizontal bridge to lift and move heavy loads within industrial settings. It is commonly used in warehouses, factories, and construction sites.

Sinoko Overhead Cranes offer enhanced safety features, durable construction, and high lifting capacity. Our cranes are designed for easy operation, ensuring efficient material handling and long-term reliability in various industries.

Sinoko Overhead Cranes come in various lifting capacities ranging from small (1 ton) to heavy-duty (up to 800 tons). We can also customize cranes based on specific load requirements.

With proper maintenance, a Sinoko Overhead Crane can last 20-30 years, depending on usage and operating conditions. We offer maintenance services to ensure long-term performance.

Sinoko Overhead Cranes are widely used in industries such as construction, manufacturing, mining, steel mills, shipbuilding, and more, to handle heavy loads safely and efficiently.

Yes, Sinoko offers customized overhead cranes tailored to your specific needs, including load capacity, span, and environment conditions. Contact us to discuss your project’s requirements.