Electric open winch double beam crane mainly consists of bridge, trolley and mechanism, crab and electrical appliances. There are Pave the rail for the trolley move on the main girder.trolley is a rigid frame welded by steel plate. Main hoisting mechanism, auxiliary hoisting mechanism and trolley operating mechanism are on the trolley.

They are applicable to be the transfer, assembly, check and repair as well as load and unload at mechanic processing workshop, subsidiary workshop of metallurgical mills, warehouses, goods yard and power station.

Features

Double girder overhead crane lifting mechanism can be with two trolleys, double trolley generally used

for lifting special materials, its structure is safe and reliable, with strong practicability.

According to user requirements, it can be:

2. Double beam crane with grab, Grab is a kind of hoist lifting spreader which can grab varieties of bulk

materials, divided into four rope type, double rope type, single rope type, electric type, discs type, shear type, hydraulic type and log type, etc.

3. Double beam crane with Electromagnetic.Electromagnetic crane is evolved from bridge double girder

crane, with detachable electromagnetic chuck and configure the corresponding operating system to con

trol the electromagnetic chuck handling and lifting metal objects;

4. Double beam crane with magnet and carrier-beam.

Trolley and Crane Traveling Mechanism:

Trolley and crane operating mechanism are composed of motors, reducers, couplings, brake and wheel

set, etc. The wheel runs in two directions driven by reducers and couplings under driving moment gene

rated by motors, trolley and bridge frame can achieve lifting back and forth from place to place.

Specification

| Technical parameter of double beam crane | ||||

| Capacity | 5, 10, 16/3.2, 20/5, | 75/20, 100/20, 125/32, | 300/40, 350/75, | |

| 32/5, 50/10 | 160/50, 200/50, 250/50 | 400/80, 450/80 | ||

| Span(m) | 10.5-31.5 | 13.5-31.5 | 17-22 | |

| Max. Lifting | Main Hook | 20 | 22 | 24 |

| Height | Aux. Hook | 22 | 22 | 32 |

| Steel Track Recommended | 43kg/m or QU70 | QU100 | QU120 | |

| Working duty | A3- A7 | |||

| Working temperature | -10℃-- 40℃ | |||

We believe that high-class electric winch double beam crane with reasonable price would definitely become your

superior alternative.

Packing& Shipping

Customer visit

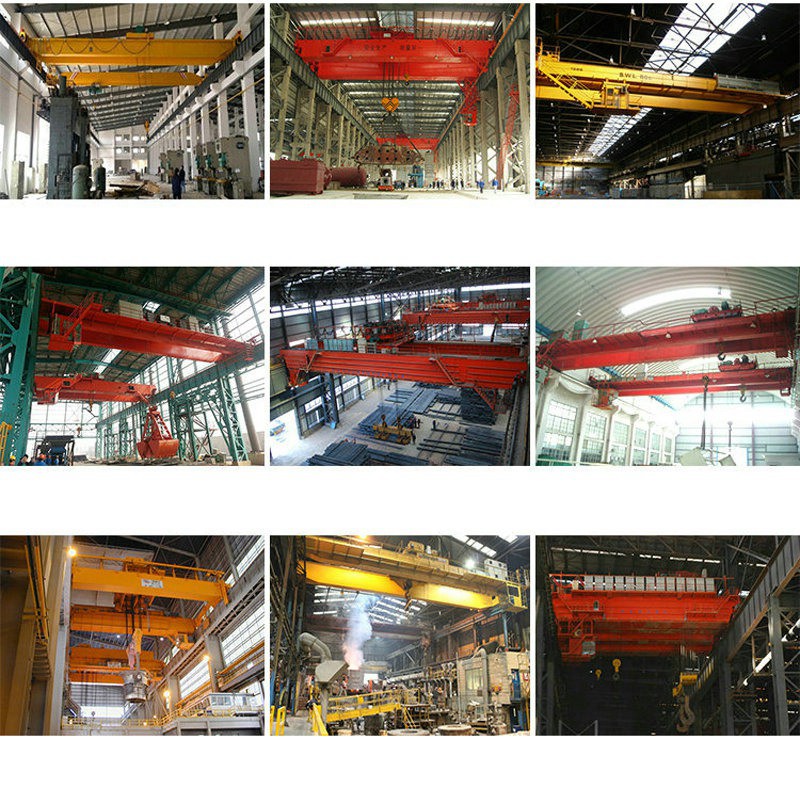

CASE

See Sinoko double beam cranes handling molten steel, port machinery, and factory assembly lines worldwide. Discover how our robust designs outperform in extreme conditions.

3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

Standard delivery takes 14-16 weeks. Need it faster? Rush orders ship in 10 weeks with 5% priority fee.

Our heavy-duty models handle up to 500 tons - proven in steel mills lifting melted metal. Most workshops use our 50-100 ton versions.

Works reliably from -10°C to 150°C. For foundries, we add heat shields at no extra cost.

Book anytime! See our production line and test 100-ton cranes in action. We'll arrange airport pickup.

①Automatic overload cutoff②Emergency stop on pendant/cabin③Power-loss protection④Anti-collision sensors⑤Storm locking system