Overview:

Features

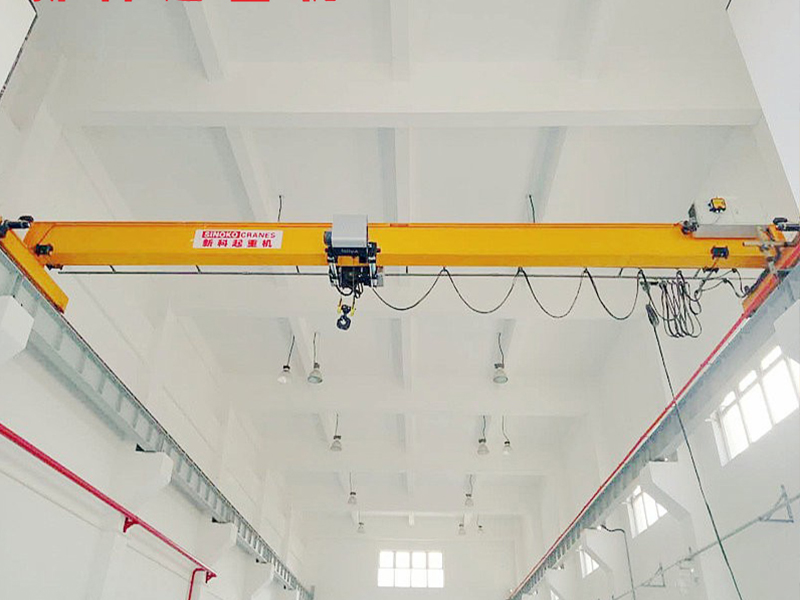

Due to the unique design referring to European FEM standard, this type of overhead crane has the advantages as bellow:

For the new factory it could be designed smaller and more functional.

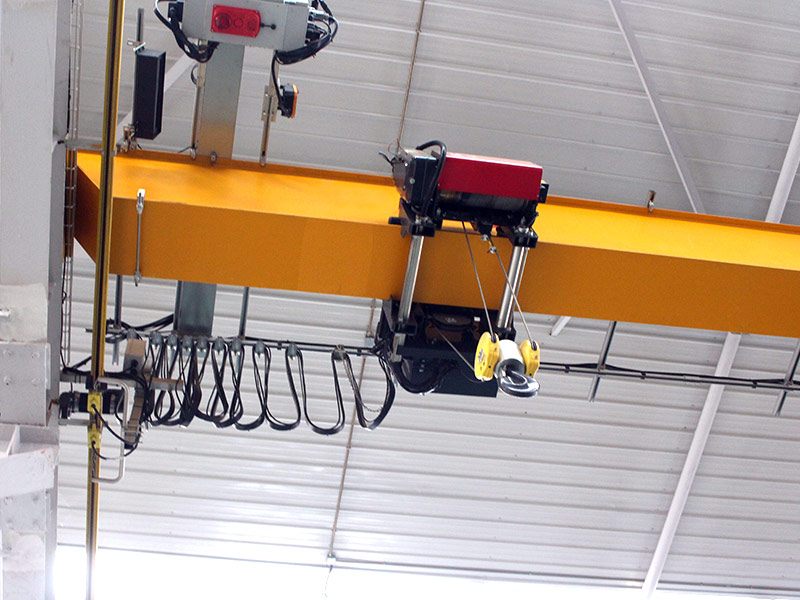

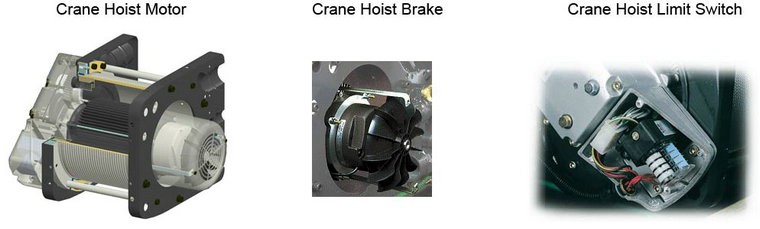

1. Mechanical parts

2. Electric Parts

3. Safety Protection System

4. Crane control mode

Kindly please provide the following information when sending enquiry to us.

Specification

Load capacity | ( ) | Tips:1t 2t 3t 5t 10t 15t 20t |

Span | ( ) | Tips:7.5m-31.5m |

Lift height | ( ) | |

voltage | ( ) | 380V 50Hz AC 3-phase or please note |

Working Class | ( ) | Tips: A5 if you don't know, please not |

Hours per day | ( ) | |

Control way | ( ) | Tips: remote control, cabin control or pendent control |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: 40% more vertical space utilization with only 200mm headroom clearance and 300mm minimum hook-to-wall distance. Ideal for low-ceiling workshops.

A: 20-ton capacity using Q345B steel beams with CNC-cut camber curves. Structural bolts (10.9 grade) ensure roof safety.

A: Yes - IP55-rated components with rain covers, dust-proof control boxes, and zinc-plated cable slides for corrosion resistance.

A: Triple protection: motor anti-fall brakes, wireless collision sensors, and dual-redundant limit switches. Includes audible/visual alarms.

A: 35% energy savings via three-in-one VFD drives, hardened wheels, and epoxy-coated steel (140μm thickness) for longevity.

A: Pendant, remote, or cabin control. All wiring uses aviation plugs and numbered PVC cables (450/750V rated) for easy maintenance.