Overview:

Underslung Traveling Single Girder Hoist Overhead Crane is a kind of Light Duty Crane. This kind of crane are very smart. Easy installed on traveling H beam. Saving the workshop room clearance. Since the H traveling channel would be more smooth than normal rail. It could increase a lot for underlung crane wheel using life.

Load Capacity: They can handle loads of up to 8 tonnes. Some versions can manage a Safe Working Load (SWL) of up to 10 tonnes, depending on the span.

Span: These cranes can cover spans of up to 25 meters.

Ceiling-Suspended: The cranes' tracks are installed on the ceiling, making them ideal for low buildings and complicated building situations.

Optimal Space Utilization: They have small side approach dimensions and custom main girder cantilevers to maximise the use of the available building width.

Hook Position Optimization: The cranes allow for the highest hook position to be optimized by adjusting the main girder's height between the end carriages.

Accessories: A comprehensive selection of accessories and components is available, enhancing the functionality and versatility of the cranes.

Intelligent Functions: These cranes have the option for smart functions with the crane control, contributing to more efficient operations.

Features

| Product details and components | |

Small Body Great Ability High Wisdom Optimized design, light weight, low wheel pressure, low height. Hardened surface flexible drive, compact structure. Frequency control, stable operation. Real-time security monitoring to ensure safe transportation. Standardized configuration, so that performance must be stable. Suitable for rated load up to 32t. |  |

Electric Hoist: Subvert the traditional, self-contained Low headroom design. Flexible drive, low internal stress, high transmission efficiency. Heavy-duty motor, electrical continuity rate 60% ED. Walking frequency stepless speed regulation, stable operation. Self-adjusting electric disk brake, reliable, dustproof. 2160N/mm2 high-strength galvanized steel wire rope, maintenance-free. Full-circle rope guide, anti-loosening rope. The entire system is equipped with a security right monitoring system. |  |

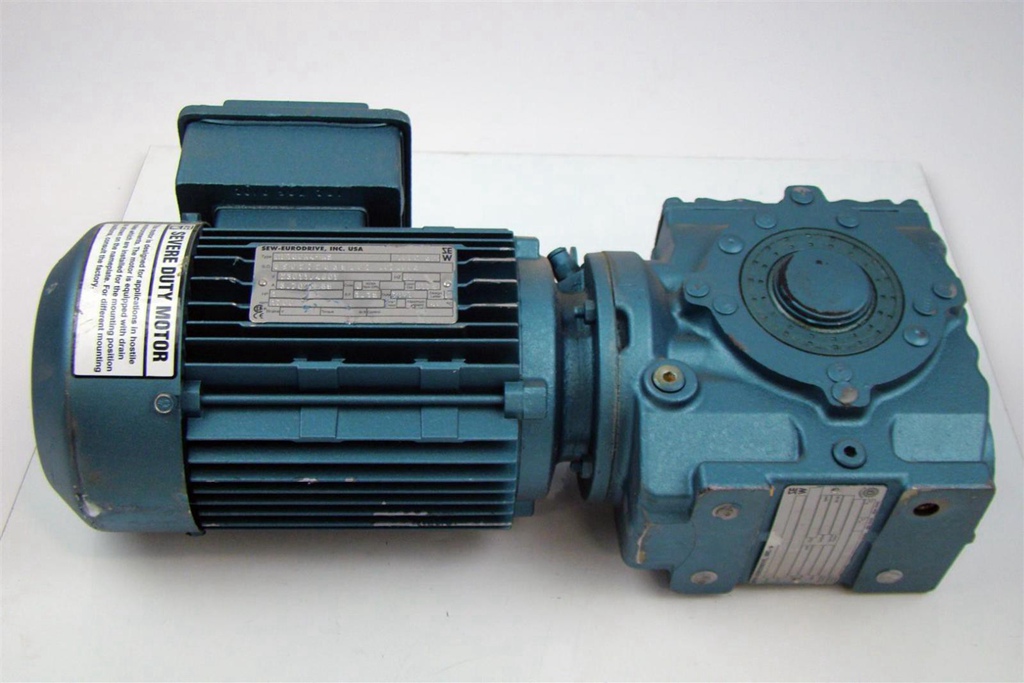

Trolley&Bridge Drive: Silent Technology, Quiet Transport Compact structure, aluminum alloy subject, sealed. Variable frequency motor + hardened gearbox + disc brake. Three-in-one integrated design. Full frequency control. he highest speed 4800r/min. Protection class IP55. Semi-lubricated, maintenance-free. Silent technology, quiet enjoyment of handling. |  |

Intelligent electronic control: security control Smart Security Monitor. Calculate the remaining safe working time of lifting agencies. Cumulative lifting time. Cumulative overload. Accumulated lifting motor start times. Lift motor overheat protection and alarm. Brake pad thickness alarm. Telecommunication. Schneider Electric Components. Aviation socket interface. IP55 protection level. | |

Bridge End Beams: flexible and adaptable Modular direct drive design. Light weight, small size. A variety of connection methods, flexible installation dimensions. Applicable to various factories, reduce the height of the factory. QT700 wheels, self-lubricating, more silent. Use self-aligning bearings to adapt to more comfortable. | |

Specification

| Capacity | 0.5 t -10t | |

| Span | 7.5m-30 m | |

| Work Duty | FEM 2m | |

| Max Lifting Height | 30m | |

| Speed | Lifting | 5/0.8 m/min Double Speed |

| Cross Travelling | 2~20 m/min VFD Control | |

| Long Travelling | 3~30 m/min VFD Control | |

| Control Method | Pendent line control | |

| Level of Protection | IP55 | |

| Insulation Grade | Class F | |

| Power Source | 380V 50Hz 3Ph AC or Customized | |

Don't miss out on the perfect lifting solution for complex building conditions! Experience the versatility and efficiency of Sinokocranes underslung overhead travelling cranes today. Request a quote now!

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

A: Underslung cranes mount directly to your building’s ceiling support structure (like H-beams), maximizing vertical clearance. This makes them perfect for low headroom buildings, complex layouts, or where floor space is limited. They eliminate the need for costly runway support columns.

A: Our cranes handle capacities from 0.5 tonnes up to 10 tonnes (SWL), with some designs optimized for up to 32t. Capacity depends on span and building structure – we provide custom solutions.

A: We offer spans from 7.5 meters up to 30 meters. The actual achievable span depends on building support capabilities and load requirements.

A: Absolutely. Designed to FEM standards, they are rated for Duty Classes A5 to A7 (Medium to Very Heavy Duty), ensuring reliability in demanding environments like manufacturing, warehouses, and assembly lines.

A: By traveling on ceiling-mounted tracks instead of elevated runways, they: Require no floor columns, freeing up workspace. Feature low headroom hoists and optimized hook heights. Have small side approach dimensions for tight spaces.

A: Yes. Our cranes feature standard VFD (Variable Frequency Drive) control for both cross traveling (2-20 m/min) and long traveling (3-30 m/min), ensuring smooth acceleration, precise positioning, and reduced load swing.