Overview:

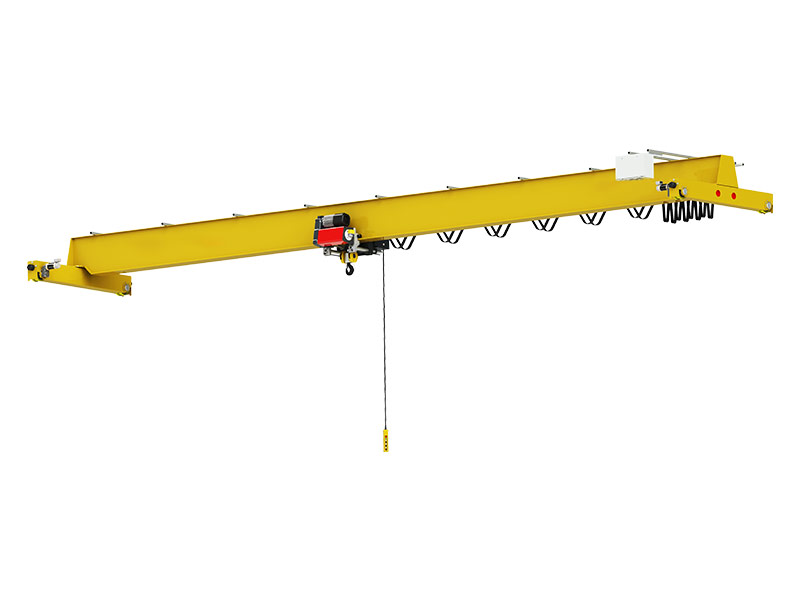

Compared with traditional cranes, the minimum distance from the hook to the wall is the smallest and the height is the lowest. Monorail Roof Cranes are able to approach walls and have a higher height, which actually increases the factory's effective working space. Due to its lighter weight and lower wheel pressure, the new plant can be designed with smaller space and more features. A smaller seminar means that people can save a lot of money for initial construction investment, long-term heating, air conditioning and other maintenance costs.It is mainly used as workshop lifting equipment.

The hoist trolley adopt Europe three-in-one drive form, the harden gear face reducer has good performances in compact structure, low noise, no oil leakage and long service life. The hoist cross travelling and lifting are all by VVVF control. You can choose SINOKO CRANE design hoist and the original SWF brand hoist for your

End beam is made of rectangular steel-pipe or steel plate by welding, the finished end beam get once positioning processed on numeral control machine in order to ensure dimension accuracy.

![[www.shpzqz.com]_029f_1510630343866081 - 副本 (2).jpeg [www.shpzqz.com]_029f_1510630343866081 - 副本 (2).jpeg](http://www.chinacranemanufacturer.com/Content/upload/2018250018/201805181949342111423.jpeg)

Surface of electric cabinet is dealt with through antisepsis plastic spraying, reasonable layout, easy maintenance, with protection level IP55, layout in electric cabinet is reasonable in order to ensure easy reparation

Specification

European Type | |

Condition | New |

Type | Single Girder Crane |

Span | up to 35 m |

Lifting Speed | 5/0.38 m/min |

Cross Speed | 0~30 M/Min (VVVF) |

Working Class | A5 |

Origin | Henan, China |

Load Capacity | 5t to 40t |

Way to Control | Pendant Push Button / Wireless Remote Controller |

Trademark | SINOKO CRANES |

Specification | CE, ISO |

HS Code | 8426112000 |

Motor | ABB Brand |

Reducer | SEW Brand |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

A Workshop Overhead Traveling Roof Crane is a versatile lifting solution designed for workshops and factories, providing efficient handling of heavy loads and materials across production areas.

Sinoko Roof Cranes offer high load capacity, smooth operation, and customizable configurations to suit various industrial environments, improving productivity and safety.

Sinoko Roof Cranes are available in various lifting capacities, ranging from 1 ton to over 100 tons, depending on the needs of your workshop or production line.

Yes, Sinoko Roof Cranes are fully customizable, including options for different spans, heights, control systems, and additional safety features to fit your operational requirements.

Regular maintenance, safety inspections, and using appropriate lifting techniques are essential for ensuring the safety and longevity of your Roof Crane.

Sinoko provides full installation services, and our Roof Cranes come with detailed manuals for regular maintenance, including lubrication, checks on mechanical parts, and electrical components.