Technological Highlights of Low Headroom Bridge Crane

1) Main beam use bias-rail box type structure, with optimized design and light self-weight.

2) The welding of main beam should be performed on working platform. In order to avoid distortion of main beam, our company adopts U-shaped main beam assembly machine with hydraulic forming which has won national patent ensuring that vertical deflection degree between joint edge of stiffened and web plate and upper cover cover should not more than H/200, and also efficiently reduce the partial wave of web plate.

3) Layout repair walkway on the drive sides of crane along the direction of main beam.

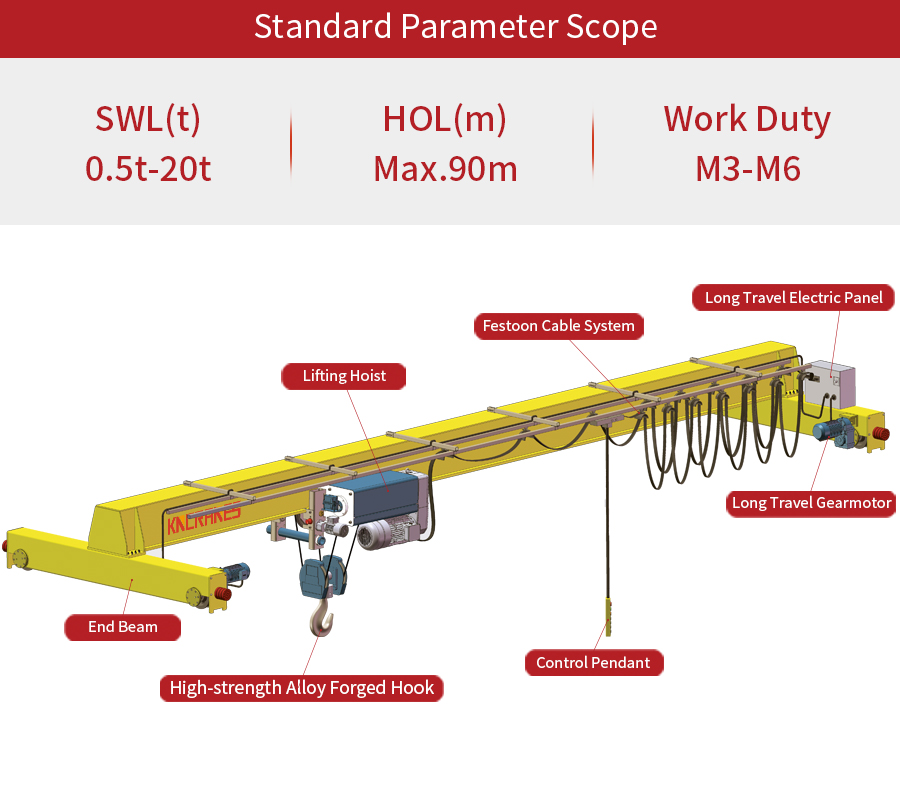

2. End beams

1) Material of end beam uses Q345B steel.

2) End beam is made of rectangular steel pipe or steel plate by welding, the finished end beam get once positioning processed on numeral control machine in order to ensure dimension accuracy and fit tolerance.

3) Each end beam is supplied with wheels with double wheels with double wheel rim, buffer and anti derailing protection device.

3. Connection of main beam and end beams

Connect main beam with end beam through bolts with end beam through bolts with high strength ensuring precision and smooth running of crane.

4. Conductive frame of crane and trolley

Conductive frame employs modular design and which consists of U-shaped bolt, connecting plate and rectangle pipes, the length and height can be arbitrarily regulated as well as easy installation.

It has complete equipments including main isolation switch, emergency disconnect switch, protection for short circuit, pressure loss, zero position , excitation loss, over current and over speed, which sufficiently implements conception of safety first.

Features

Low clearance and small size.

Light deadweight.

More efficient workplace.

Adopt famous brand structure, Siemens motor, Schneider Electric, French wire rope, etc.

Double lifting speed, variable frequency running speed.

Specification

The above technical lights are all low headroom bridge cranes. They are also what convince our customers to choose our crane products as their workshop or industrial lifting equipment.

| Specification | Value |

| Capacity | 1 ton to 20 tons |

| Span | 6m to 31.5m |

| Work duty | FEM2M, M5 |

| Protection class | IP55 |

| Insulation class | F |

| Continuing rate | 60% (for high-class motor) |

| Cooling rate | 30% higher than normal crane |

| Over temperature protection | 170℃ |

These specifications suggest a high-quality, durable crane that is capable of handling heavy loads in a variety of industrial settings. The FEM2M and M5 work duty ratings indicate that the crane is designed for heavy use, while the IP55 protection class and F insulation class indicate that the crane is well-protected from dust, moisture, and other environmental factors.

The continuing rate of 60% and the cooling rate that is 30% higher than normal suggest that the crane is designed to operate for extended periods of time without overheating. Finally, the over-temperature protection feature ensures that the crane will shut down automatically if it exceeds a safe operating temperature, helping to prevent damage and ensure safe operation.

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

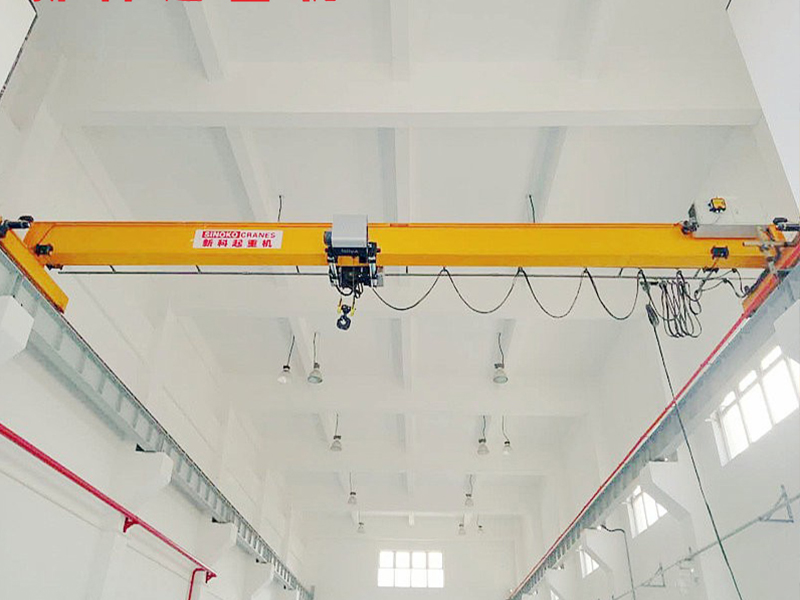

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

A Wireless Control Monorail EOT (Electric Overhead Traveling) Crane uses wireless technology for remote operation, offering precise and safe lifting of heavy loads in various industrial applications.

The crane is equipped with a wireless control unit that allows operators to lift, lower, and move loads remotely, improving safety and flexibility in operations.

Advantages include increased operational safety, enhanced convenience, reduced labor costs, and improved precision in lifting operations without the need for direct contact.

This crane model can handle load capacities ranging from several hundred kilograms to 20 tons, based on the specific configuration and application requirements.

Commonly used in manufacturing, warehouses, logistics, automotive, and construction industries for precise material handling and lifting tasks.

Yes, the crane can be customized to suit your specific needs, including load capacity, control system options, span, and more, to optimize performance in your facility.