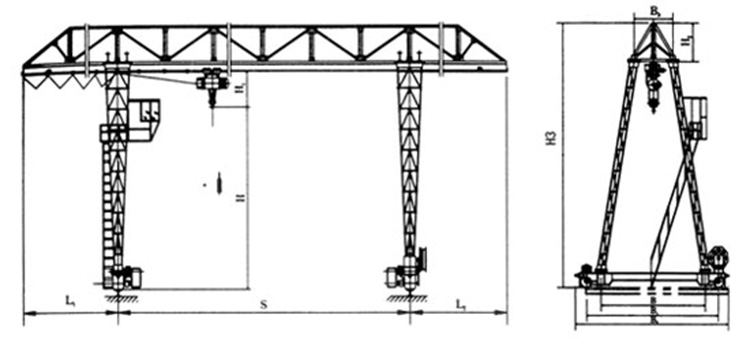

The truss gantry crane is mainly composed of truss beams, outriggers, lower beams and other components. The structural components are connected by shafts, which are convenient for disassembly and transportation.

As one type of lifting machinery equipment, adapts to be used in the places where exist strong wind. It is widely required by the customers who come from coastal areas.

Truss crane in our group is of light dead weight, small loading capacity, and strong wind-resistant ability. With its simple structure, its construction cost is relatively low compared with ordinary box-shaped gantry crane.

Features

1. Intelligent overload limiter in the hoist improves the cranes safety maximum.

2. Our polyurethane buffer is of high-class quality, durability and shock-resistance.

3. Advanced emergency shutdown system.

4. Hoisting limiter, travel limit switch of cranes promises safety work.

5. Integrative out-voltage protection and phase protection.

6. Power production capacity, professional technicians, and excellent services.

7. Strictly delivery inspection guarantees high-class quality products.

Specification

Rated load/ton | 5 ton | 10 ton | 16 ton | 20 ton | 32 ton |

Span/m | 10-40 | ||||

Lifting height/m | 30 | ||||

Working class | A3-A5 | ||||

Lifting speed/m/min | 8 | 7 | 3.5 | 3.5 | 3 |

Trolley running speed/m/min | 20 | 20 | 20 | 20 | 20 |

Crane running speed/m/min | 20 | 20 | 20 | 20 | 20 |

Dead weight/t | 10.5~37.5 | 16.8~52 | 18.9~65 | 24.5~77 | 27.5~98 |

Number of wheel | 4 | 4 | 4 | 4 | 4/8 |

Max. wheel pressure/KN | 52.5~12.1 | 95~183 | 131~242 | 167~298 | 238~41.5 |

Steel track recommended | P24 | P38 | P43 | P43 | P43 |

Power supply | 3AC 220~480V 50/60Hz | ||||

CASE

When heavy loads transcend spatial constraints, when precision meets industrial scale—every gantry crane redefines the boundaries of productivity.

Pakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a Quote40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteFAQs

Ideal for handling steel pipes, cement, stone blocks in quarries, ports, and roadside construction sites.

Engineered for high-wind zones! Withstands Beaufort Scale 8 winds (17m/s) during Hainan typhoons. Triangular truss structure reduces wind resistance by 40% vs box-type gantries.

Modular axle connections enable: ①Largest component <3m after disassembly (fits standard trucks) ②3-person assembly in 4 hours ③10-language installation videos included

Standard CD1 electric hoist (8m/min lift). Manual chain hoists available (-30% cost) but reduce efficiency by 60%.

Triple protection: ✓ Automatic power cut at 105% overload ✓ Dual limit switches (travel + height) ✓ Polyurethane buffers (85% collision absorption) ✓ Voltage-drop protection (safe unloading)

Lightweight design saves: ① 35% less steel ② 50% lower transport costs ③ 1/3 foundation work