As one of the most frequently used material handling equipment, Electric winch trolley overhead crane is a double girder overhead crane with the hook as the lifting tool. The lifting capacity of the double girder electric winch crane is 5 to 550 tons, and the working class is A4 to A7

Features

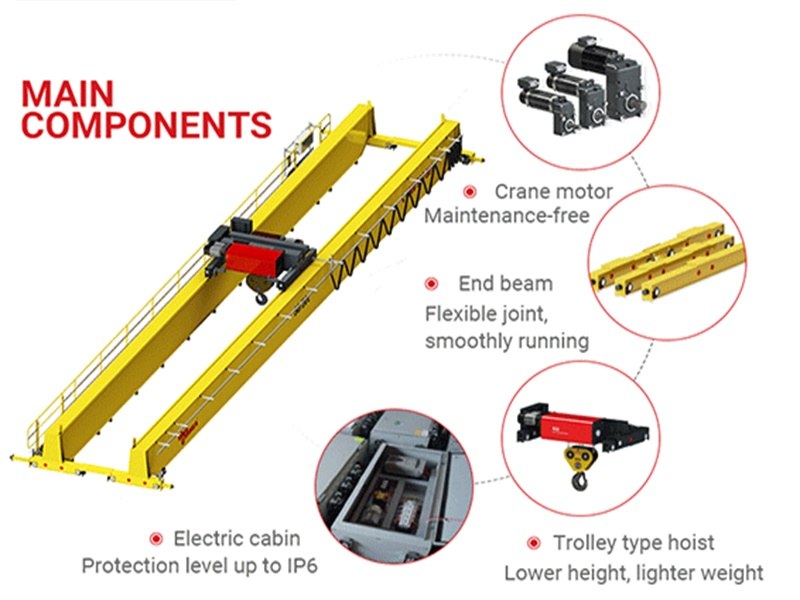

1). Reasonable structure,strong bearing capacity

2). Low noise, soft starting and stopping

3). Safe and reliable operation

4). Commodious cabin and open view

5). Low cost maintenance, long working life

6). Strong box type,welding by machine hand.

7). Wheels are vacuum casting,medium frequency quenching

8). Wheels,wire rope drum,gears, couplings are processed by CNC manchine center, TOP quality control.

9). Heavy duty slipring motor,Or Sq.cage motor with VVVF, IP54 or IP44,insulation class F or H,soft starting and smooth running.

10). Siemens main electric parts are used for durable and safe operation

Specification

| Overhead Crane Product Type | QD |

| Lifting Capacity | 5~550t |

| Span | 10.5~35.5m |

| Working Class | A4~A7 |

| Working Temperature | -20~40℃ |

CASE

Interested in how our European-style QD overhead cranes operate in demanding steel plant environments? Explore real-world case studies to discover how Sinoko delivers high-performance lifting solutions tailored to heavy-duty industrial needs.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

This crane supports a wide range of lifting capacities—from 5 to 550 tons—with customizable span lengths between approximately 10.5 to 31.5 meters, making it suitable for diverse steel plant layouts.

The Europe‑style QD crane boasts a robust box‑type frame, soft start capabilities, low noise operation, driver’s cabin with excellent visibility, and key safety devices such as overload protection, buffer stops, and limit switches.

Designed for industrial environments, it operates on 220–440 V, 50/60 Hz, three-phase power, adheres to working-duty classifications from A4 to A7, and functions reliably in temperatures ranging from –20 °C to +40 °C.

Operators can choose from multiple control options—desktop pendant control, wireless remote operation, or an ergonomically designed driver’s cabin—to suit workflow and safety needs.

Thanks to its compact and lightweight design, this crane reduces floor space requirements and wheel pressure, improves energy efficiency, and delivers smoother movement—offering higher return on investment compared to standard cranes.

Absolutely. Custom options include explosion-proof configurations, high-temperature components, dual hooks, load-weight display systems, PLC integration, and specialized attachments like magnets or C-hooks to meet unique steel plant demands.