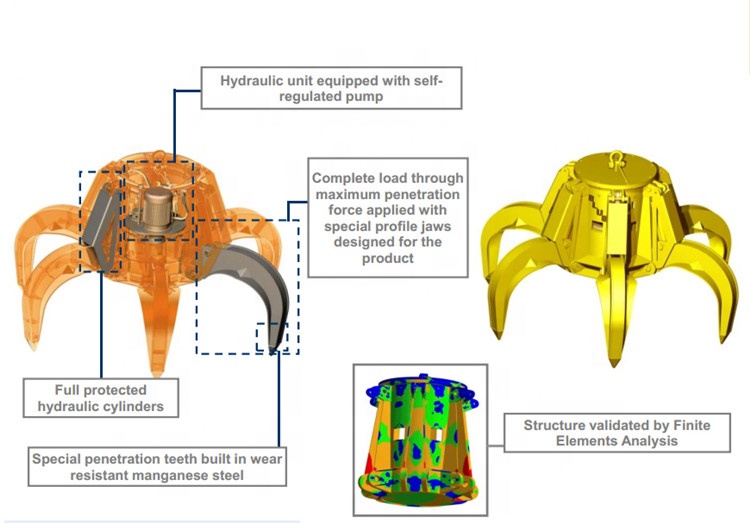

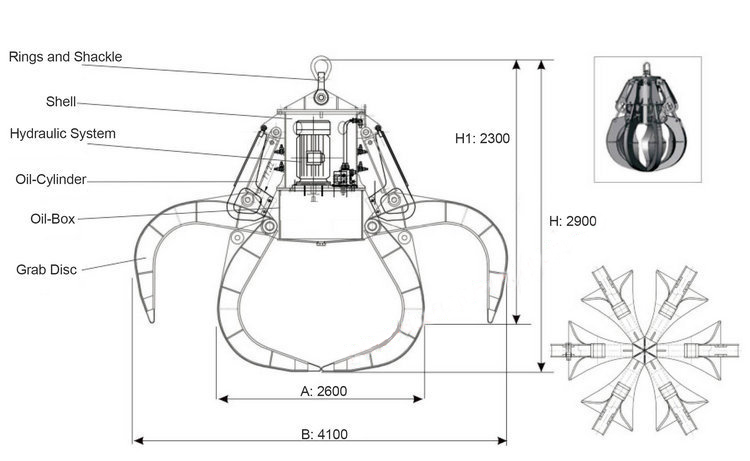

Grabs For Scrap Handing has hydraulic power and control system itself, and the hydraulic power system is imported from Europe and USA. The grab uses constant output pump and servo system. The flow of pump can change by itself according to working pressure. When the pressure reaches the max pressure, the flow is almost zero, so it can reduce the overflow, and reduce the temperature rise of oil. The opening and closing is controlled by valves or positive inversion motor which ensures the grab can positive inversion rotate frequently. The grab can be designed as half-close or full-open type with long teeth. The peels of the grab are particular, it is easy to grab scrap steel. The grab has six or eight peels, and each peel is driven by an oil cylinder, so the material won’t leak. The grab has tie-in on the grab and it is easy to connect to the crane.

By replacing the structural form of the upper connecting ring, the scrap steel grab can be installed on various types of cranes, grabbers, and excavator power main equipment to achieve various operations in freight yards, wharfs, stations, stock yards, and steel industries. Loading, unloading, unstacking, stacking and other operations of materials are carried out on occasions.

Features

1. Our motor hydraulic grab feature high productivity, long life span and low costs.

2. Some parts, for example, cylinder bolts or clamshell bolts are never subject to change, if they are greased properly.

3. Lowest running costs per ton material transferred: good performance, high productivity, low maintenance cost, and high reliability.

4. We adopt imported brands for the design of main hydraulic system components, such as motor, valves, sealing and etc.

5. Our electric scrap grabs have advantage of low operation height, variable displacement pump, powerful digging force, simple structure, easy operation, low noise, and stable in working under any circumstances.

6. The cylinder never gets rust.

7. The shells are available in open, half closed and closed versions and with every kind of possible opening direction and with diverse cable patterns.

8. The robust design of the electric grab is manufactured with high-tensile steel. It is lightweight, with excellent filling and digging and fast emptying capabilities.

Specification

| Type | Density | Volume | Grab Weight |

| t / m3 | m3 | kg | |

| DYP6-2.0-1.5-00 | 1.5 | 2 | 3000 |

| DYP8-3.1-1.5-00 | 1.5 | 3.1 | 3300 |

| DYP10-4.2-1.5-00 | 1.5 | 4.2 | 3600 |

| DYP12-4.5-1.5-00 | 1.5 | 4.5 | 5200 |

| DYP16-6.8-1.5-00 | 1.5 | 6.8 | 5800 |

| DYP20-8.6-1.5-00 | 1.5 | 8.6 | 7000 |

| DYP24-10-1.5-00 | 1.5 | 10 | 9000 |

| DYP28-13-1.5-00 | 1.5 | 13 | 9500 |

| DYP30-15-1.5-00 | 1.5 | 15 | 10000 |

| DYP32-17-1.5-00 | 1.5 | 17 | 10500 |

CASE

Our project case studies demonstrate how Sinoko’s orange-peel grabs are used across industries to streamline scrap loading, increase safety, and boost material handling efficiency. Explore real-world examples of customized solutions tailored to challenging environments like steel mills, scrap yards, and recycling centers.

Pakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

A: The orange-peel hydraulic grab is engineered for high-density, heavy scrap—perfect for scrap steel, discarded vehicles, machinery, and other dense metallic waste—providing reliable handling in steel, recycling, and freight environments.

A: It features a self-adjusting variable-output pump (with servo control) that slows flow as pressure peaks, minimizing overflow and temperature rise. This ensures smooth operations, reduces heat buildup, and prolongs system life.

A: The grab boasts a sensible structural design, soft-start/stop controls, quiet operation, excellent visibility from the cabin, plus easy-to-replace components and low upkeep costs.

A: The grab peels are available in open, half-closed, and fully closed configurations, with six or eight tines—driven individually by cylinders—to ensure efficient gripping with minimal leakage and superior control.

A: Absolutely. By modifying the upper connecting-ring structure, the grab can be fitted easily to various crane types—including overhead cranes, gantry cranes, and even excavators—making it highly versatile for yards, stations, ports, and steel plants.

A: Built with robust hydraulic motors, valves, and seals from trusted global suppliers, reinforced steel construction, and components that—if properly lubricated—can last for years, this grab offers exceptional productivity, long service life, and very low operating costs per ton moved.