CD MD Wire Rope Hoist is the most popular hoist for single girder cane, because of their characteristics of tight structure, smart body, safety and reliability, common-used parts, well changeable property, strong lifting capacity as well as convenient maintenance. also can work by fixing to a section of I-beam. It is a light duty designed.

Features

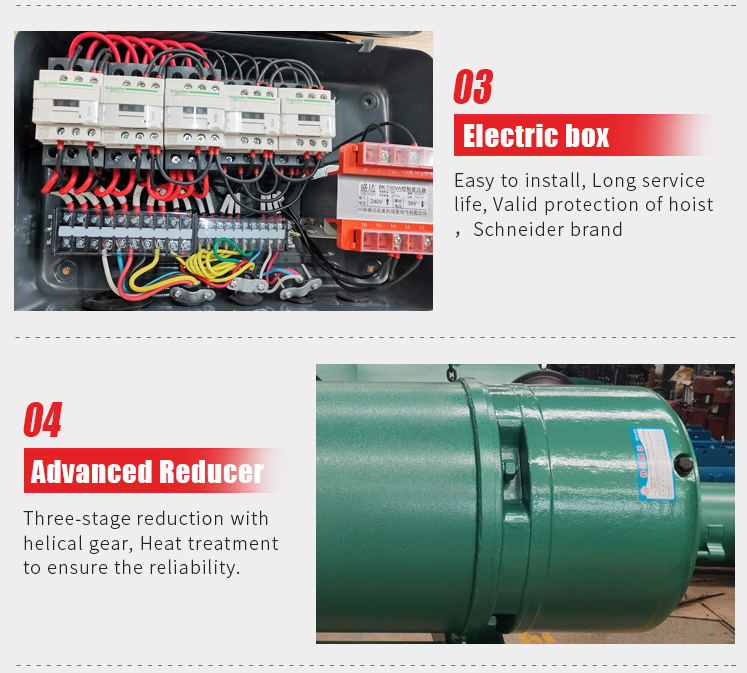

Reducer of CD MD Electric Wire Rope Hoist

It adopts a three-stage locking motor gear transmission structure; the gears and gear shafts are made of alloy steel after heat treatment, and the shell and cover are made of high-quality cast iron, with accurate assembly and good sealing. The reducer operates independently for easy loading and unloading.

Control box of CD MD Electric Wire Rope Hoist

It has a protection device for up and down trip circuit breakers, which can cut off the main circuit in an emergency to ensure the safe operation of the electrical block, long service life, and safe operation of electrical components.

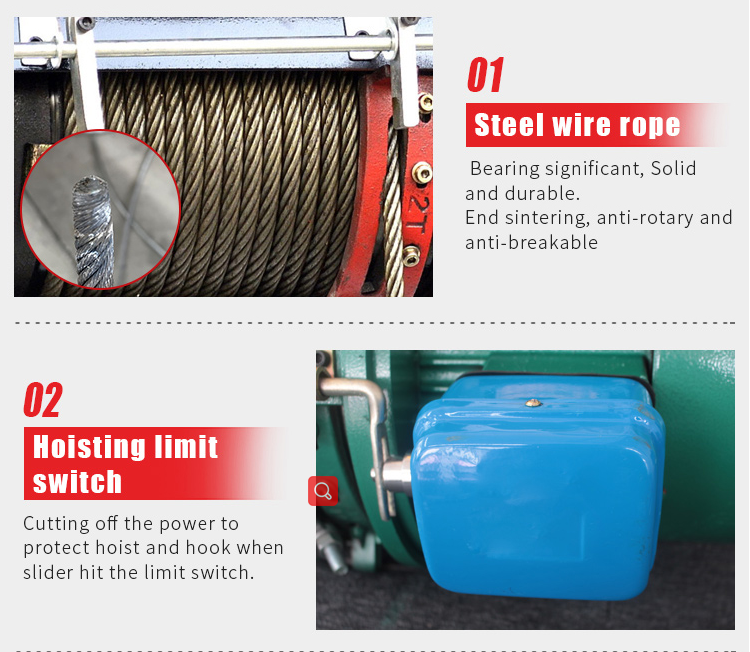

Wire rope of CD MD Electric Wire Rope Hoist

Use GB1102-74 (6 * 37 + 1) hoisting steel wire rope, long service life.

Cone motor of CD MD Electric Wire Rope Hoist

The hoisting motor uses a cone motor with a large starting torque to brake the induction motor. No additional lightning arrester is needed. The load continuity factor of the motor is 25%; the motor uses B and F insulation, and the protection level is isIP44 / IP54 .

Push button switch of CD MD Electric Wire Rope Hoist

It is manual operation, easy to operate, there are two ways of rope operation and wireless remote control.

Gear of CD MD Electric Wire Rope Hoist

It adopts Japanese technology, innovatively adopts high-speed synchronous gear symmetrical arrangement, and adopts international standard gear steel. Compared with ordinary gears, it is more wear-resistant, more stable and labor-saving.

Specification

| Type | CD MD Wire Rope Hoist | |||

| Lifting Height/T | 1 | 3 | 5 | 10 |

| Hoisling Height/m | 44742 | 44742 | 44742 | 44834 |

| Hoisling Speed m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) |

| Rope Dia/mm | 7.7 | 13 | 15 | 15 |

| Rope Specification | 6*37+1 | 6*37+1 | 6*37+1 | 6*37+1 |

| Lifting Motor Power/kw | 1.5 (0.2/1.5) | 4.5 (0.4/4.5) | 7.5 (0.8/7.5) | 13(1.5/13) |

| Travling Motor Power/kw | 0.2 | 0.4 | 0.8 | 0.8*2 |

| Crane Weight/kg | CD:137-220 | CD:281-451 | CD:437-726 | CD:1048-1411 |

| MD:164-247 | MD:311-481 | MD:530-783 | MD:1104-1467 | |

CASE

Discover how businesses across industries are using Sinoko’s electric wire rope hoists to improve safety, efficiency, and productivity in their lifting operations. Our project case studies showcase proven results, practical solutions, and customer success stories from around the world.

5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: The CD1/MD1 electric wire rope hoist supports capacities from 0.5 ton up to 20 tons, including commonly used options like 1 ton, 3 ton, 5 ton, and 10 ton models—all designed for single-girder crane applications.

A: These hoists accommodate a lifting height of up to 30 meters, providing flexible vertical reach for various lifting needs.

A: They operate on 220–440 V, 3-phase, at 50/60 Hz, and are rated for ISO M4 working duty, suitable for many industrial applications.

A: The hoists feature a three-stage geared reducer with alloy steel gears and cast-iron housings. They include upper/down limit circuit breakers, emergency power cutoff, and can be controlled manually via push-button or remotely via wireless, ensuring both safety and operational flexibility.

A: Each hoist uses a 6×37+1 wire rope, with diameters increasing based on capacity (e.g., 7.7 mm for 1 ton, up to 15 mm for 10 ton). Motors are cone-type with high starting torque, featuring IP44/IP54 protection and B/F insulation for durability.

A: These hoists are prized for their compact design, lightweight build, high reliability, common interchangeable parts, and low maintenance cost, making them a cost-effective solution for enhancing efficiency in a wide range of lifting operations.