China hydraulic orange peel grab bucket for eot bridge crane is a special tool for cranes to grab dry bulk cargo. The grab operation does not require heavy physical labor, can achieve high loading and unloading efficiency and ensure safety. It is the main dry bulk handling tool of the port. According to the type of goods, it can be divided into ore grab, coal grab, grain grab, wood grab.

According to the driving method, it can be divided into two types: hydraulic grab and mechanical grab.

The mainstream grabs are as follows:

Shell type grab: suitable for port, dock, station yard, mine and other aspects of loading a variety of bulk cargo, minerals, coal, sand and gravel materials, earth and stone.

Multi-petal grab: Suitable for scrap steel grabbing and refining work in steel mills, bulk waste in waste disposal sites and construction sites, waste refining, handling and handling.

The wood grab is mainly used for the grasping and loading and unloading of logs, wood, pipes, drums and other objects of various specifications. It can be grabbed by a single grab or multiple picks, and can be used with cranes such as tower cranes and door cranes. Applicable to occasions such as log yards, dock unloading, etc.

Features

* Suitable to grab sand, coal, grain, slag, scrap

* through beam is shortened, high strength, light self-weight;

* main shaft sleeve is of bearing steel, Pin shaft material is 40Cr,

* High-temperature resistant bearing for the pulley,

* knife edge plate adopts wear-resisting steel plate, adopts multilayer sealing craft,

* dirt proof and waterproof and it could be underwater operation.

* Clearance of two knife edge plate is very small,0.3mm, good sealing, keep working site clean.

* the whole structure is strong and not distortion, good sealing.

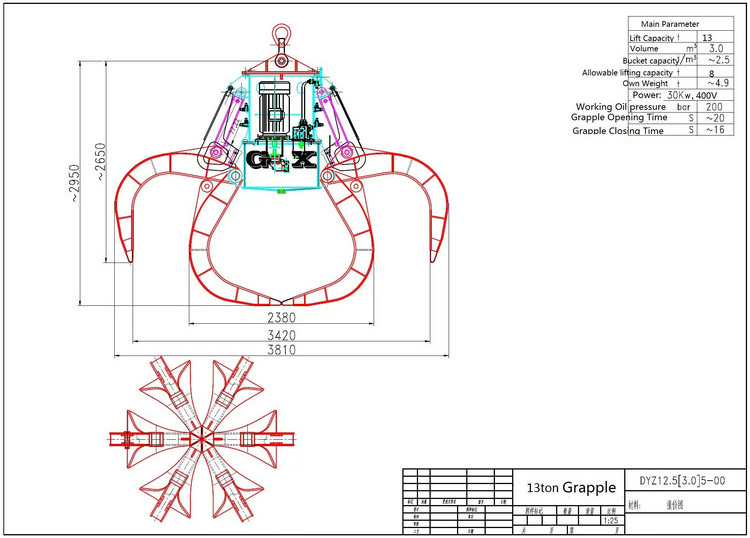

Specification

CASE

Explore how our hydraulic orange peel grab buckets are successfully used in crane projects across industries—from steel plants to ports and recycling facilities. These case studies highlight practical applications, technical solutions, and measurable results achieved with Sinoko equipment.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

A: It excels at handling dry bulk and irregular materials—like sand, coal, grain, slag, and scrap—and is specifically engineered for efficient loading and unloading using EOT (Overhead Traveling) bridge cranes.

A: It’s built with a shortened through‑beam for high strength and light weight; a multi‑layer seal and a mere 0.3 mm gap between knife‑edge plates ensure good sealing; made from wear-resistant steel and sturdy components, it’s dirt‑proof, waterproof, distortion‑resistant and even suitable for underwater operations.

A: Sinoko offers models from 0.5 m³ (DYZ3, 1.5 t self‑weight, for 3.2 t cranes, 11 kW motor, 180 bar, ~10 s close time) up to 20 m³ (DYZ30, 11 t, for 30 t cranes, 45 kW, 200 bar, ~28 s).

A: Yes—its sealing craftsmanship, high‑quality bearing components, and wear‑resistant construction allow reliable operation even when submerged or exposed to dirt and moisture.

A: Hydraulic grabs use cylinders for smoother, faster, and more precise opening and closing; they often include optional rotation. Mechanical versions rely on ropes and pulleys—simpler and cheaper, but less precise and slower, making hydraulic versions preferable for repetitive heavy‑duty tasks.

A: They are widely deployed in ports, steel mills, waste and recycling centers, and other industrial settings—especially where irregular, bulky, or abrasive materials such as scrap, slag, demolition debris, or steel residues need precise and powerful handling.