The wire coil lifting tong’s clamp is driven by a torque motor. The two clamp legs are driven to tighten or loosen through the sprocket and the gear rack of the worm gear reducer.

After lifting the steel coil, the machine is locked, even if there is a misoperation, the clamp will not open in the air

The clamp can be equipped with a rotating head, and the clamp can be rotated horizontally within a range of 360º during operation.

Light weight, simple operation, flexible and reliable action, safe and convenient transfer, and high work efficiency. It is mainly used for the transfer of large quantities of horizontal roll objects in steel plants, ports, wharves and other units.

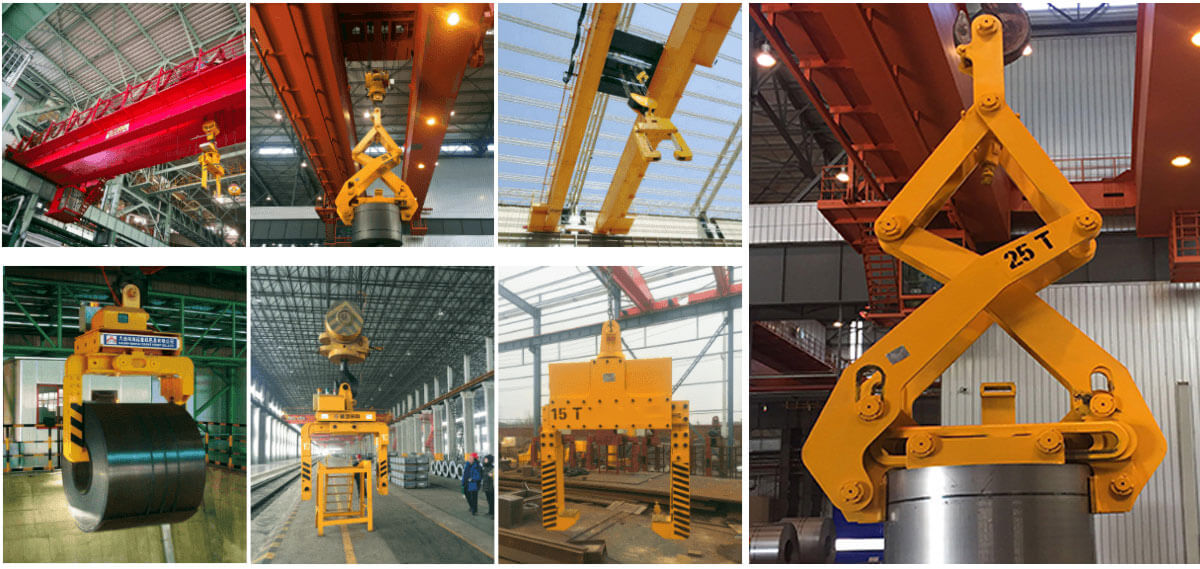

At our company, we have a wide range of coil handling products, including coil tongs, that are designed to meet the diverse needs of our customers in the coil handling industry. Our coil tongs are carefully designed and customized to perfectly suit your specific requirements and applications.

Features

1, There is Electro-optical Sensor Protection System to protect the coil not be broken by coil lifter (especially for cold rolling coil).

2, Electrical system is controlled by PLC and provide generic interface, it is low breakdown, easy installation and realize "Plug & Work" function.

3, There is torque limiter system to prevent the damage by Lock-Rotor, it make the motor durable.

4, There is ratchet system in Open/Close mechanism, the opening of arms is locked if there is no command for open arms, it will prevent the coil lifter open its arms by accident.

5, There is rotation mechanism (optional) that coil lifter can rotate and stop in any angle what is preset.

6, There is automatic hook hanging mechanism (optional) that we can hang the coil lifter to hook by automatically, the work of hanging will be safe and simple.

This type of the Coil Lifter is most widely used. It is moderate price, easy to operate, provide good protection for coil.

Specification

| Specification | Value |

| Type | Vertical / Horizontal / Tilting / Rotating |

| Capacity | Customizable based on coil weight |

| Grip Range | Adjustable to accommodate different coil sizes |

| Material | High-strength steel construction |

| Grip Surface | Non-slip coating or specialized material |

| Actuation | Manual or powered actuation |

| Safety Features | Latch or lock mechanism for secure gripping |

| Customization | Tailored design for specific coil dimensions |

| Compliance | Designed to meet industry standards and safety regulations |

Project Case

Contact us today to discuss your specific coil handling requirements, and let our team design a customized coil tong that perfectly suits your needs. Experience the reliability and efficiency of our tailor-made coil tongs for your coil handling operations.

CASE

Explore our crane project case studies to see how industries worldwide are using Sinoko solutions to handle steel and paper coils safely and efficiently. From heavy-duty manufacturing to port logistics, our equipment is engineered to meet complex lifting demands with precision and reliability.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

The lifter is available with capacities ranging from 10 t to 50 t, accommodating a wide scope of coil handling needs with customizable options based on coil weight.

This tong includes an electro‑optical sensor protection system, PLC‑controlled electrical interface, torque limiter, ratchet mechanism, and mechanical automatic locking after power loss—ensuring secure, reliable coil gripping with fail‑safe protection.

Yes. It can be equipped with an optional 360° rotating head, enabling smooth horizontal rotation of the coil during handling operations.

The system is designed to lock mechanically after lifting, even in case of unintended miscommands or power shutdowns. It also offers manual opening or closing in emergency situations.

Yes—it features a PLC-based control system with a generic interface, making installation straightforward and enabling plug‑and‑work functionality. Suitable for both manual and powered actuation depending on user preference.

Primarily designed for handling horizontal rolls, this lifter is ideal for operation in steel plants, ports, and wharves, offering high efficiency, lightweight operation, and safe handling of heavy horizontal coils.