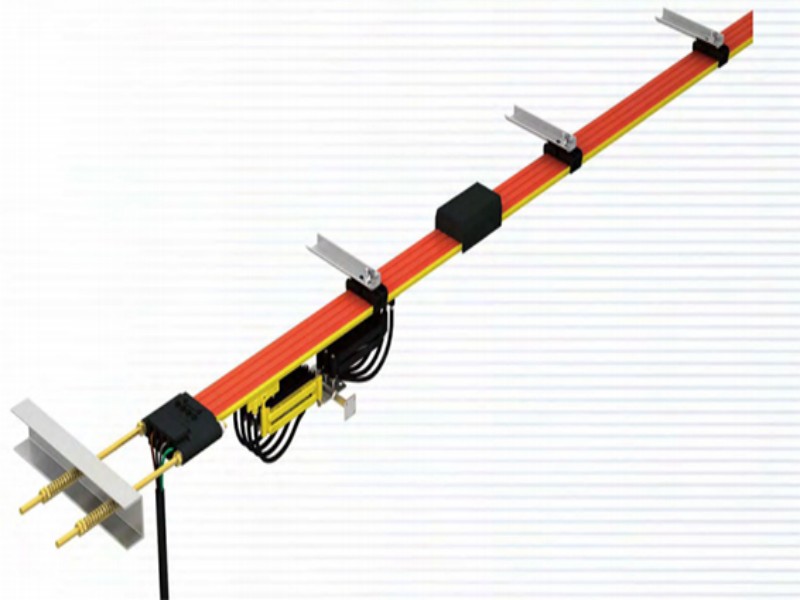

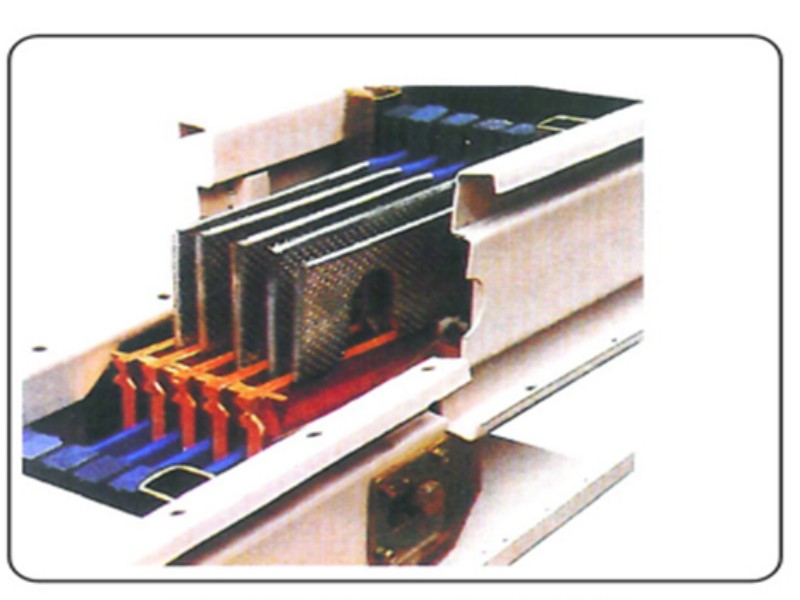

Crane Power Conductor Line is a slide line with the function of preventing accidental impact and hazard. It can be used indoors and outdoors. The structure is an engineering plastic insulated shell, which can be loaded with copper wires of different cross-sectional areas. And Crane Power Conductor Line's rated current value is 35A to 240A. The operation of the relay is guided by the tractor, which is mainly transmitted by the carbon brushes with springs.

Features

1. Safe and reliable, with IP 43 .

2. Waterproof and dustproof to prevent fingers from electric shock.

3. Energy saving and consumption reduction. The use of international conductive materials can reduce the power loss in the electric circuit to the greatest extent.

4. The maximum moving speed is 200m/min.

5. Easy to install and maintain.

6. Long service life, unique formula of conductor sheath, greatly increase the service life of the slide conductor system.

7. According to the working condition of the equipment, the bending and sliding wire system can be made.

8. The insulation sheath is added with anti-ULTRAVIOLET component, suitable for outdoor.

9. Provide standard PVC insulated sheathing and PPO heat-resistant insulated sheathing, suitable for different working environment.

10. The whole series of products can meet the VO extreme fire rating, -40 degree environmental requirements.

Specification

| Type | Specification | Length (m) | Weight (kg) | Max.current (A) |

| H-402-6mm2 | 6mm2 | 1 | 0.69 | 30A |

| H-402-10mm2 | 10mm2 | 0.83 | 50A | |

| H-402-16mm2 | 16mm2 | 1.04 | 80A | |

| 16mm2/10mm2 | 0.99 | 80A | ||

| H-402-25mm2 | 25mm2 | 1.36 | 120A | |

| 25mm2/10mm2 | 1.23 | 120A | ||

| H-402-35mm2 | 35mm2 | 1.72 | 140A | |

| 35mm2/10mm2 | 1.49 | 140A | ||

| H-402-45mm2 | 45mm2/16mm2 | 1.82 | 180A |

CASE

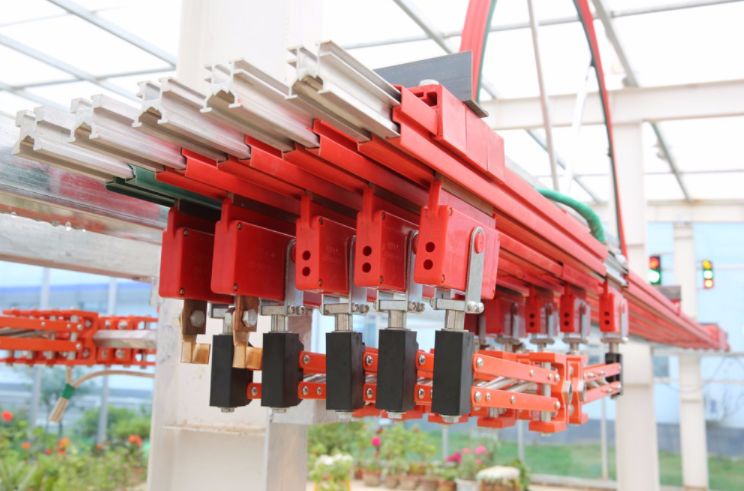

To help you better understand how our conductor line systems support bridge crane operations in diverse environments, we’ve highlighted a series of project case studies. These examples showcase how Sinoko Crane’s power solutions are applied in real industrial scenarios—improving efficiency, reliability, and safety. Discover how our technology performs in the field and adapts to the specific needs of our global clients.

5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteFAQs

Sinoko Crane's power conductor systems typically use three‑phase 380 V (±10%) at 50 Hz. They can also be customized for voltages up to 690 V and frequencies of 50–60 Hz, or even single‑phase supplies depending on regional requirements.

Common options include sliding contact lines (conductor rails) and cable line supply. Sliding contact lines are compact and easy to maintain, though they may offer less weather resistance. Festoon cable systems are more flexible and resistant to wear, oils, and corrosion.

Ensure flat cable layout, secure compression of pressure plates, and consistent cable diameter across layers to prevent stress concentration. Suspended cables should be organized using harnesses, and when cable trolleys create a 120° angle, the tow wire must be tensioned and straightened correctly.

Generally the crane delivery time is 20 to 40 working days, electric hoist lead time is 15 working days, jib crane is about 20 working days.The delivery time will be longer if the product is customized according to special requirements.

Seamless conductor systems provide joint‑free, compact solutions that save space, come with PVC housing for impact and UV resistance, and offer good insulation. They're cost‑effective and ideal for curved rail hoists and low‑frequency operations.

These systems deliver reduced voltage loss and better heat dissipation thanks to superior conductivity and low impedance. Their simple, composite structure lowers maintenance demands, aids safe operation, and—when seamless—can save around 10% in energy compared to traditional supply methods.