Overview:

The 15ton overhead crane usually adopts single girder or double girder according to the customer's work situation.

One major difference between single beam and double beam models is price. The cost of producing a single girder crane is lower than that of a double girder due to the fact that the single girder has less material and takes less time to manufacture.

Double beams overhead crane can withstand greater work intensity. If you are not sure whether to choose double beams, you can send us your working time, and our engineers will design exclusive material handling equipment for you.

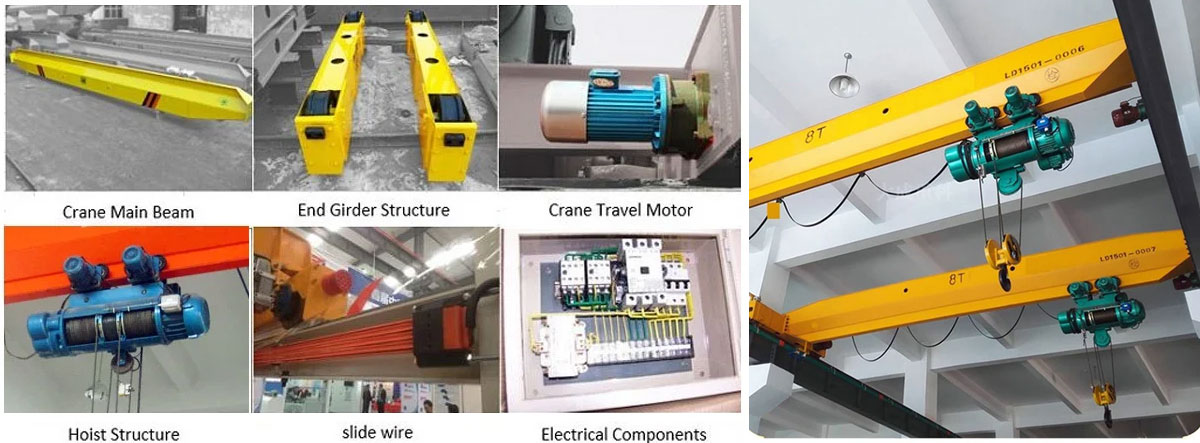

Brief Introduction of LDA 15 ton overhead crane

Model: LDA

Capacity: 15ton

Lift Height: 3m to 30m

Span: Max. to 65m

Duty Class: A3, A4

Power Supply: 380V, 50Hz, 3-phase AC, 220V, 60Hz, 3-phase AC

Advantages of LDA 15 ton overhead crane

1. Push button of control: the life can reach 200000 times.

2. Electrical adapt as Chint, SIMENS, or Schneider.

3. Motor Choose China best motor brand: Nanjing special motor.

4. Soft start motor make the traveling smoothly.

5. Brake from Jiaozuo brake factory, China best brand.

6. LYC bearings which is serve for the the Shenzhou spacecraft

Safety Features of LDA 15 ton overhead crane

1. Emergency stop system

2. Limit Switch for Lifting

3. Limit Switch for Travelling

4. Overload protect device

5. High quality buffer

6. Current overload protect device

7. Voltage Lost protect device

Specification

| Code | LDA |

| Lift Capacity | 15T |

| Span | 7.5~22.5M(Other on customerized) |

| Lift Height | Customerized |

| CT Speed | 20/30m/min |

| Duty Classification | A3 |

| Dead weight | 2.54~6.05T |

| Max.wheel Load | 35.8~45KN |

| Min. wheel Load | 4.2~13.4KN |

| Lift Speed | 8m/min |

| LT Speed | 20/30m/min |

| Dia.(Drum) | 15mm |

| Model(Wire Rope) | 6*37+1 |

| Width (Crane Rail Head) | 25a-45c |

| Motor Model | Cone squirre-cage model |

| Lift Motor Model | ZD141-4 |

| Power(Lift Motor) | 7.5KW |

| Rotation Speed (Lift Motor) | 1380r/min |

| Current(Lift Motor) | 18A |

| CT Motor Model | ZDY121-4 |

| Power (CT Motor) | 0.8KW |

| Rotation Speed(CT Motor) | 1380r/min |

| Current (CT Motor) | 2.4A |

| LT Motor Model | YSE802-4/YSE90L-4 |

| Rotation Speed (LT Motor) | 1380r/min |

| Power (LT Motor) | 2*0.8/2*1.5KW |

| LT Motor Model | ZDR100-4 |

| Power (LT Motor) | 2*1.5KW |

| Power Source | 220V~480V, 50Hz/60Hz, AC |

| Control Model | Cabin, remote control, pendent control with push button |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Our 65m max span design supports workshops up to 300m² using: • Q345B steel girders with camber optimization • QU120 rails for reduced deflection (

A: Yes! Schneider VVVF upgrade provides: • Soft-start/stop (0.1m/s² acceleration control) • 35% energy savings vs contactor systems • ±10mm precision positioning for delicate loads

A: Full CE/ISO 12482 compliance featuring: • Dual-redundant limit switches (upper/lower) • Emergency stop on pendant and cabin • Overload protection (±3% accuracy) with auto-lock

A: 2-person installation in <8 hours due to: • Pre-assembled modular components • Bolt-on connection system (no welding) • Guided video tutorials (scan QR code)

A: Nanjing ZD-series motors deliver: • 200,000+ duty cycles (Class H insulation) • IP54 protection against dust/moisture • Thermal cutoffs at 150°C for burnout prevention

A: Our optional automation kit enables: • Laser-guided load positioning (±5mm) • RFID zone recognition for repeat tasks • Remote monitoring via Sinoko IoT platform