Overview:

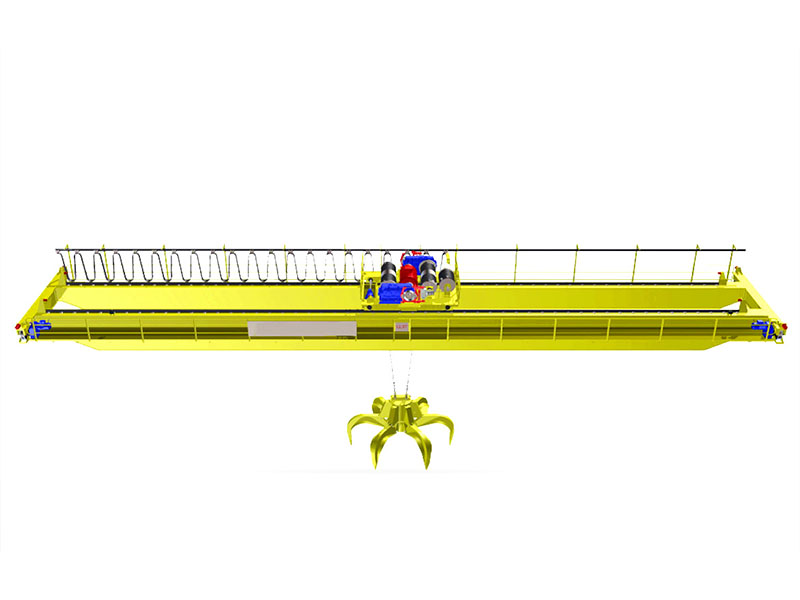

According with different working efficiency, different material density, size, weight etc. Sinokocranes could make most suitable type grab cranes.

Technical Features:

How to choose a Overhead grab crane or Grab Gantry Crane for your factory or plant?

Specification

| Model | QZ Moded BndgeCrane wh Grab | ||||||

| Lting Capacity(T) | 5T | 10T | 16T | 20T | |||

| Max Liting Haigit (M) | 20m | 18m | 22m | 26m | |||

| Span (M) | 10.5-31.5 | ||||||

| Workang Systam | A6 | ||||||

| Speed M/Min | Trolley | Hoisting | 40.1 | 40.7 | 41.8 | 48.6 | |

| Traveling | 44.6 | 45.7 | 43.2 | 43.2 | |||

| Crane Traveling | 93.7-114.4 | 112.5-101 | 98-87.3 | 87.3 | |||

| Wight | Trolley | 5.2/5.9 | 8.2/9.1 | 14.8/15.9 | 19.3/20.4 | ||

| Total | Indoor | 19.9-41.3 | 26.5-50.4 | 47.3-67.9 | 56.1-75.6 | ||

| Outdoor | 20.7-42.1 | 27.4-51.2 | 48.5-69 | 57.3-76.8 | |||

| Grab | Volume | 2.5-0.75 | 5-1.5 | 8-2.5 | 10-3 | ||

| Dead weight (KG | 2632-2546 | 4800-4793 | 7841-8305 | 9812-10123 | |||

| Rail recommended | 43kg/M,QU70 | ||||||

| Power Source | 380V 50HZ 3Phase AC(or as your demand) | ||||||

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteFAQs

A: Built for heavy-duty steel scrap, demolition waste, stone, and bulk materials. Compatible with orange peel grabs (for irregular scrap) or finger grabs (for loose materials).

A: Yes. Features include: IP56-rated rain covers for outdoor use Laser height measurement for precision Overload protection and emergency stops -20°C to 50°C operating range

A: Three control modes: Manual (radio remote) Semi-automatic (single-command) Fully automatic (self-positioning via laser)

A: Depends on your material: Orange peel grabs: Sharp/dense scrap Finger grabs: Loose/shredded material Hydraulic vs. mechanical: Faster vs. economical

A: Yes. Dual grab/magnet systems allow switching between ferrous and non-ferrous materials without crane changes.

A: Custom-engineered solutions from 5 to 50+ tons with spans up to 40m. Share your daily volume/load size for precise specs.