European type electric hoist bridge crane design is following FEM standard.

Features

1. Use optimized computer design box type girder as main support girder.

3. Unique wheel frame design, help to adjust balance and install, stable structure.

4. Motor protection class is IP54, F class insulation and equipped with overload protection equipment.(optional)

5. Specially designed gearbox for crane, adopts oblique gears, self-lubrication.

6. Control stick could be connected with trolley, freely move on main girder separately and can also control the travelling speed according to the different depth of bottoms.

Specification

| Capacity (kg) | 3200 | 5000 | 6300 | 8000 | 10000 | 12500 | ||

| Lifting Height (m) | 6/9/12/15/18 | |||||||

| Lifting Speed (m/min) | 5/0.8 | 5/0.8 | 5/0.8 | 5/0.8 | 5/0.8 | 5/0.8 | ||

| Lifting Motor (kw) | 3.2/0.45 | 6.1/1 | 6.1/1 | 9.5/1.5 | 9.5/1.5 | 12.5/2 | ||

| Traveling Speed(m/min) | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 | ||

| Traveling Motor (kw) | 0.25*2 | 0.37*2 | 0.37*2 | 0.37*2 | 0.37*2 | 0.55*2 | ||

| Insulation Duty | F | |||||||

| Control Panel | IP65 | |||||||

| Working Class | Lifting | 2M / M5 | 2M / M5 | 2M / M5 | 2M / M5 | 2M / M5 | 1 Am / M4 | |

| (FEM/ISO) | Traveling | 2M /M5 | 2M /M5 | 2M /M5 | 2M /M5 | 2M /M5 | 2M / M5 | |

| Dimension | H | 500 | 520 | 520 | 550 | 550 | 550 | |

| C | 420 | 425 | 425 | 580 | 580 | 580 | ||

| Speed (m/min) | 1.2/1.4/1.4/1.7/2 | 1.4/1.4/1.4/1./2 | 1.4/1.7/1.7/1.7/2 | |||||

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Installation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

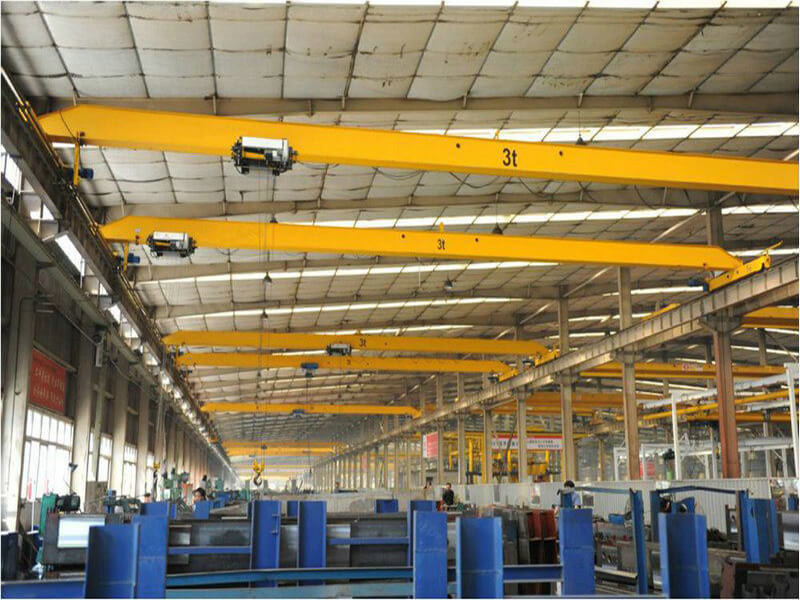

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

A: Our FEM-standard design features German dual-speed motors (IP54/F-class insulation), Italian 2160N/mm² steel ropes, and aluminum alloy gearboxes for 30% weight reduction. This creates a compact, corrosion-resistant system with lower noise and longer lifespan than conventional cranes.

A: With a max height of just 550mm (12.5T model), our optimized box girder and steel rope configuration: Save vertical clearance for low-ceiling buildings Provide wider hook coverage in confined spaces Eliminate interference with overhead infrastructure

A: Triple-layer protection: Dual-disc electromagnetic brakes at motor ends Optional overload protection systems (per FEM M5 standards) CNC-machined drum/guide systems with seamless steel pipes All controlled via IP65-rated panels for dust/moisture resistance.

A: Absolutely. Critical protections include: IP54 motor housing (resists dust/water jets) Self-lubricating oblique gears in gearboxes F-class insulation for 155°C heat resistance Corrosion-resistant aluminum alloy components

A: Our patented trolley-mounted stick: Allows speed adjustment based on load depth (5-20 m/min) Enables free movement along the girder Reduces operator fatigue through ergonomic positioning

A: Key low-maintenance features: Maintenance-free galvanized wire ropes Self-lubricating gear systems Modular wheel frames for quick balance adjustment