Overview:

QDY&YZ model casting ladle crane with hook mainly consists of main beam, hook trolley, crane traveling mechanism, cabin and electric controlling system, etc. Casting ladle crane is one of the main equipment in the continuous casting technology of steel making.

It is mainly used transfer the pouring melted iron to the appointed place, and the thermal protective coating is added at the bottom of the main girder. The place where molten nonmetal material and red-hot solid metal is lifted. The casting overhead crane are heavy duty for 20-24hours working.

Adopt double-girder structure below 125t and four-girder structure above 125t;

The main grabbing device of main hook is fixed-spacing hook girder used to lift foundry ladle;

Auxiliary hook is used to work with main hook to dump the molten iron and do other subsidiary lifting operation;

Main hoisting and transportation equipment in steel mill and smelter workshop;

Used for transshipment and pouring of liquid metal during melting, etc;

Add thermal-protective coating under the main girder;

Ambient temperature: below +60℃, moisture: less than 50%;

Crane assembly and test accord with No. 375, 2007 document issued by AQSIQ.

Casting Ladle Crane Detail Showing

1. Crane girder 2. Crane trolley 3. Gear box 4. Crane motor 5. Hydraulic brake 6. Crane wheel

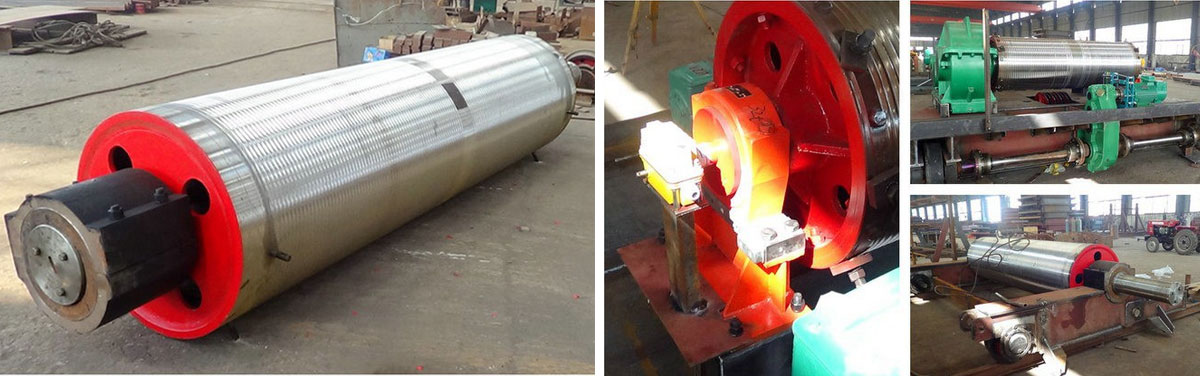

Strong Drum & Trolley Showing of Casting Ladle Crane

Following demands as optional for the QDY and YZ type casting ladle crane:

1. Capacity: 5t-500t

2. Span: 5-40m

3. Working Class: A7-A8 (FEM 4m-5m)

4. Control Method: Remote and Cabin Control

5. Power Source and Painting Color as your demands

6. According to your other demands.

Features

1. Overloading protection

10. Emergency stop system, current over-load protection system, Excellent exchangeability for parts and components

Specification

| Lifting Capacity (T) | 125/32 | 320/80 | |

| Span (m) | 19 | 24.5 | |

| Speed (m/min) | Main Hook | 7.8 | 7.6 |

| Aux. Hook | 9.7 | 9.7 | |

| Main Trolley | 36 | 38 | |

| Aux. Trolley | 37.5 | 39 | |

| Traveling of Crane | 73 | 76 | |

| Max wheel pressure (KN) | 505 | 750 | |

| Steel track recommended | QU120 | ||

| Operational Model | Cabin; remote control | ||

| Working class | A7 or A8, FEM 4m | ||

| Power Supply | Three-phase A.C. 380V, 50Hz or your requirement | ||

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Full compliance with China AQSIQ 375-2007 and FEM 4M standards, featuring: • Double-layer thermal protection under girders (≥125t) • Redundant brake systems with emergency power backup • CE-certified overload protection for molten steel

A: Our proprietary 3-layer defense system: Refractory ceramic coating (10mm) on girder undersides Active water-cooling channels for critical components Heat-shielded wire ropes (PFEIFER Thermax®)

A: 750KN wheel pressure requires QU120 rails - we provide: • Foundation load calculations • Seismic reinforcement kits for zone 8+ areas • Anti-derailment sensors as standard

A: Yes. Choose between: • Explosion-proof cabin with air purification (IP66) • 270m-range wireless control with live thermal monitoring • Both options feature dual-path signal redundancy

A: Mandatory 3-stage validation: FEA simulation of 5x dynamic loads Ultrasonic weld testing (AWS D1.1/D1.6) 48h continuous test with 125% rated load

A: Our predictive maintenance system includes: • Vibration sensors on gearboxes (SEW/ABB) • Monthly remote diagnostics reports • 5-year structural warranty (10yr on main hooks)