Overview:

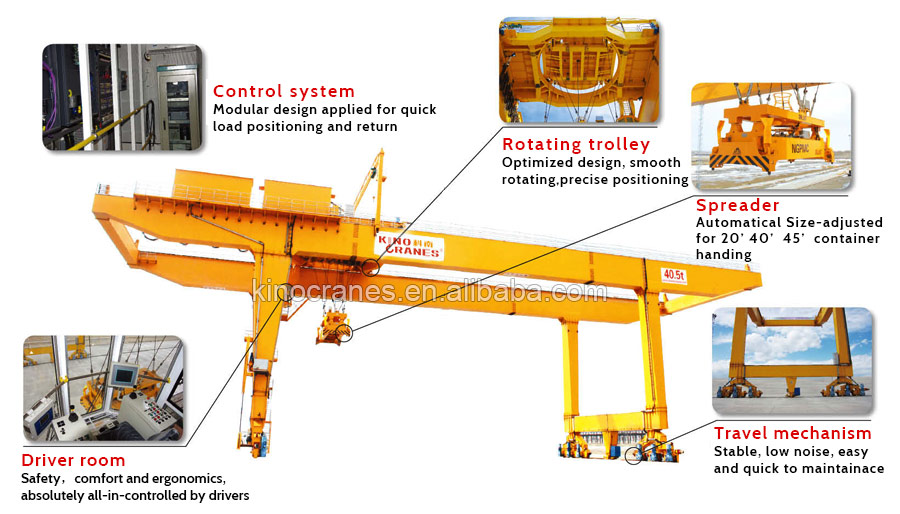

Rotating traverse overhead magnet crane has very high speeds, without compromising safety, many other safety features like heat shields, and many standard safety features like multiple overload relays, limit switches, double service brakes, etc.

Features

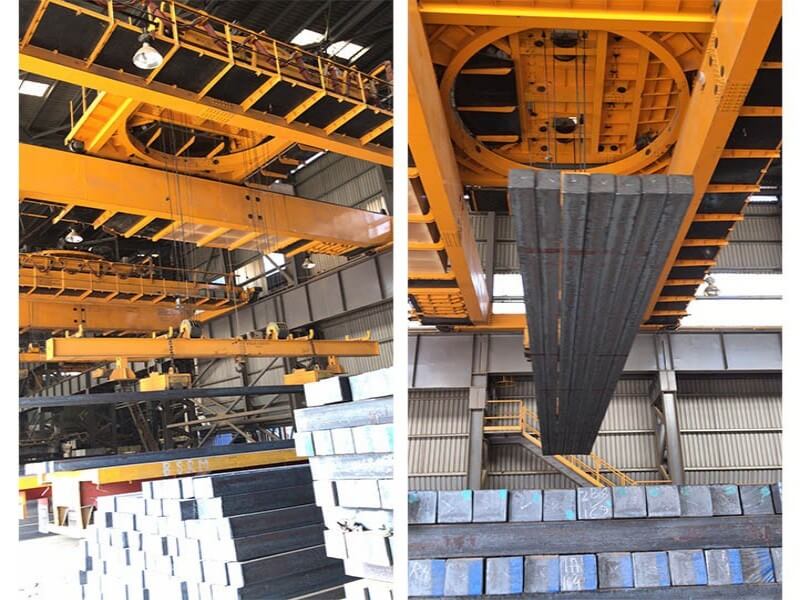

Specially designed Rotating Trolley cranes, for rotating and better positioning of slabs, drastically reduce production time and drastically reduce storage space. Overhead magnet crane with rotating traverse beam magnet spreader are specially designed to handle very high speeds, continuous operations, extreme heat transfer from hot slabs and heavy dust accumulation. SINOKOCRANES have developed a rotating trolley crane which can rotate for better positioning, storage of slabs. This crane drastically reducing production time and also space required for storage.

1. On material. All compression structural part of crane’s components is made of high quality materials confirming with the regulations and standards, whose inspection report can be provided when required.

2. On welding. The welding of steel structures will be strictly checked and inspected by specialist and the inspection reports also can be provided on requirement.

3. On magnetic chuck. The magnetic chuck has huge magnetic force which can be used to lift and transport wide range of metal products and can handle large volume of metals at a time.

4. On motor. Top brand motors are installed with good performance and with Class F insulation and IP54 protective class.

5. On electric system. PLC control to all the mechanism and any speed requirement can be achieved.

6. On control system. Cabin with joystick panel, wireless control and pendant control can be your choices.

7. On painting. 3 layers of painting is painted to protect the steel from rusting.

8. On safety. Various protection measures are taken to ensure the safety of crane and operation. Overload limit, height limit,rail end stop limit for traveling are used to protect mechanical system and short circuit protection, lose phase protection,low-voltage protection, power failure protection, over current protection are used to protect electric system.

Specification

Capacity | t | 10+10 | 12.5+12.5 | 13.5+13.5 |

Span | m | 28.5 | 28.5 | 31.5 |

Lifting height | m | 16 | 10 | 13 |

Hoisting speed | m/min | 11.4 | 11.4 | 11.4 |

Rotation speed | r/min | 0.8 | 0.8 | 0.8 |

Cab travelling speed | m/min | 38 | 38 | 38 |

Crane travelling speed | m/min | 88 | 88 | 88 |

Recommended rail | QU80 | QU80 | QU80 | |

Power supply | 3P 380V 50Hz | 3P 380V 50Hz | 3P 380V 50Hz | |

Working class | A6 | A7 | A7 |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteFAQs

A: Specialized for hot slabs, steel plates, and ferrous metals with magnetic spreaders rated up to 27 tons (13.5+13.5T).

A: 360° rotating traverse beam (0.8 rpm) enables precise slab positioning, reducing storage space needs by 30% vs. standard cranes.

A: Triple protection: Heat-shielded components IP54 motors + F-class insulation Double service brakes & overload relays

A: Operator choices: Insulated control cabin Wireless remote Joystick pendantAll with PLC precision.

A: Yes. Full rainproofing package available for outdoor installations.

A: Complies with A6/A7 duty class (FEM/ISO) for continuous steel mill operations.