Overview:

A teeming crane could charging the hot metal liquid to the converter or EAF, So it have the speed requirement of accurate positioning. Normally it need variable speed. The laminated ladle hook design of a teeming crane should be considering the ladle size .The traverse beam size also should consider the suitable size to match the furnace door.

Our company's teeming crane is customizable to meet user requirements, offering features such as adjustable speed for each mechanism (1:10 or greater), rotating hoist, variable laminated hook distance, overload limits with alarms, load weighing and display, PLC control, fault detection, display, recording, and printing system, as well as collision prevention between cranes of the same span. For more details, please send enquiry to info@sinokocrane.com.

A teeming crane have 5 types in the market. As following is 5 different structure of teeming crane.

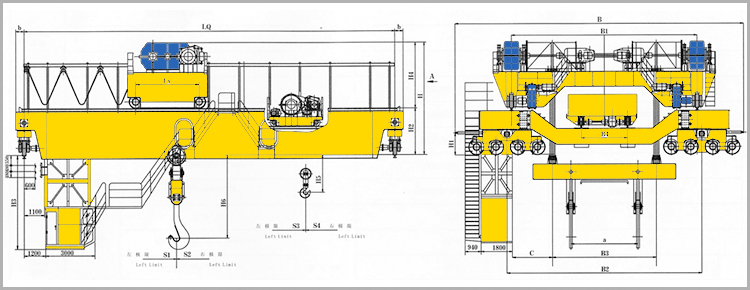

1. Four Girder Four Rail Double Trolley Teeming Crane

2. Four Girder Six Rail Double Trolley Teeming Crane

3. Double Girder Double Rail Single Trolley Teeming Crane

4. Double Girder Four Rail Double Trolley Teeming Crane

5. Double Girder Double Rail Mother and Child Trolley Teeming Crane

Features

Four Beam and Four Rail type teeming crane is a most general popular design in the crane market, Quite suitable for big capacity teeming crane 100 ton ~320 ton. The main structure of teeming crane is include electrical equipment, main trolley system, traveling system, beam structure, auxiliary trolley system, lifting traverse beam etc.

Four Girder Six Rail teeming crane is normally for extreme huge capacity ,more than 320 ton. The purpose is solving the big wheel pressure ,improve the trolley pressure for the main beam.

Double Girder Double Rail Single Trolley teeming crane is designed for small capacity 120t below ladle cranes. Main hoist and auxiliary hoist are in one trolley system. Hook distance is fixed. It has compact structure.

Double Girder Four Rail teeming crane is also for small capacity 100 ton below. It have independent main hoist trolley and auxiliary hoist trolley. This design could help the auxiliary hook to work more easily to hook the ladle.

Double Girder Double Rail Mother and Child type trolley teeming crane. The child trolley could traveling small distance on the main trolley .So that the hook distance could be adjustable .

If you want more information or need teeming crane, welcome to send enquiry to info@sinokocrane.com, our professional team will supply best solution for your steel mill.

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Triple-layer protection: ceramic thermal barriers (1500°C rated), water-cooled cables, and ATEX-certified explosion-proof cabinets ensure safety in steel plant environments. Ideal for ladle transfers near EAF/converters

A: ±3mm accuracy via Siemens S7-1500 PLC laser guidance and VVVF micro-speed control (1:20 range). Reduces spillage during converter charging

A: Four-girder recommended for 120-320t loads (optimal weight distribution), double-girder for <120t (cost-effective). Six-rail design available for >320t capacities

A: Adjustable hook span (2-5m hydraulic adjustment) and independent child trolley movement enable 30% faster ladle positioning vs. fixed hooks.

A: CE EN 15011, ISO 12482-1, and IECEx explosion protection. All electricals rated IP66 with nitrogen-purged cabinets

A: Yes - SmartPour retrofit kit enables automated pouring (±1% volume accuracy), thermal ladle monitoring, and UWB collision avoidance