Overview:

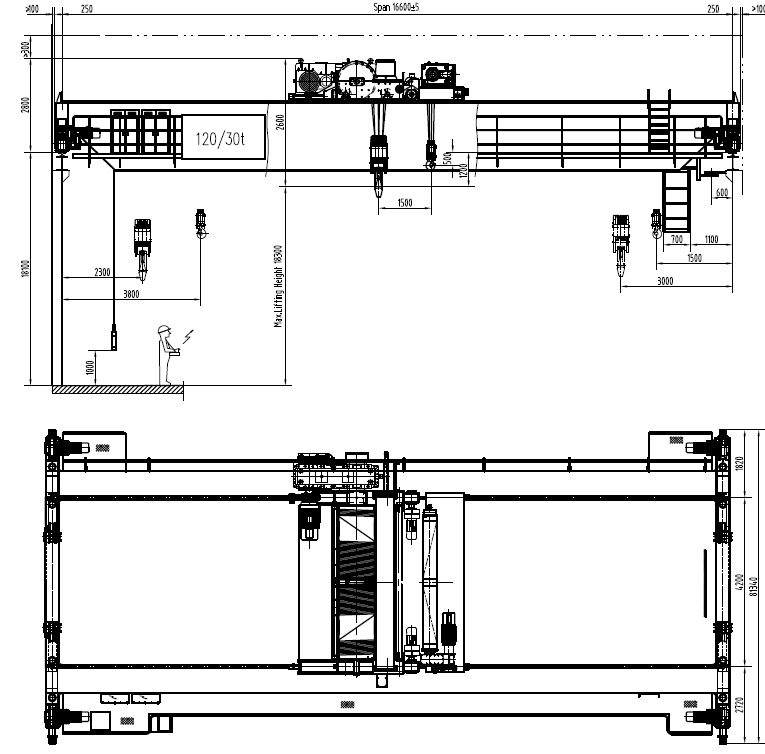

In the main house of the hydropower plant, the dam hydropower cranes are used for the key equipment installation, commissioning , maintenance etc. As the overhead cranes for turbine house, the reliability, smooth, and efficiency is the main features for those cranes.

Features

The Main feature of Dam hydropower station cranes :

1. HIGH CAPACITY:

The generator stator and rotor need to lift together after equipped, the rotors are really big and heavy, so it will need a large capacity overhead cranes for lifting. Sinokocranes could do hydropower station cranes as capacity of 100 ton,150 ton,200 ton,300ton,500 ton etc.

2. Lifting Speed is slow:

The big generators need a very accuracy lifting and installation work process.So that a very slow and smooth speed is a must requirement for hydropower station cranes.

3. HIGH LIFTING HEIGHT:

General speaking, the big hydropower station working workshop is really high, it require a high lifting height for the cranes, lifting height normally is more than 30m.

4. Low working Duty

The overhead cranes in the hydropower plant only have some work at the beginning of power plant construction. After all generators installation are finished, the crane only have very few work in following years, it will only need the cranes to do a very simple maintenance work.

Specification

| Parameter | Technical Specifications |

| Rated Load | 100t-500t (Customizable) |

| Lifting Height | ≥30m(Up to 80m) |

| Lifting Speed | 0.2-1.5 m/min (VVVF Stepless Speed Control) |

| Working Class | FEM 1M/ISO M3 |

| Rail Type | QU120-QU180 Heavy Rails |

| Control Mode | Cabin +Remote Control(IP65 Protection) |

| Safety System | ·Dual braking systems ·Real-time load monitoring ·Seismic-resistant structure |

| Seismic Resistance | 9-Degree Fortification(GB50011 Standard) |

| Environmental Adaptability | -25℃ to +60℃/RH≤98% |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Our 500-ton custom cranes handle rotors up to Ø18m, featuring: • Dual-hoist synchronization (±5mm precision) • ASME B30.2 nuclear-grade safety certification • Baihetan Dam proven solution (1,000MW units)

A: 0.2 m/min VVVF micro-speed mode with: • ±1mm positioning accuracy via encoder feedback • Anti-sway system at 30m heights • Load oscillation <2° during critical installation

A: 9-degree fortification system (GB50011): • Base isolation bearings (300% displacement capacity) • Real-time seismic monitoring sensors • Automatic lockdown at ≥PGA 0.4g

A: Triple-protection defense: ① C5-M corrosion coating (ISO 12944) ② 316L stainless steel components ③ IP66-rated electrical cabinets with dehumidifiers

A: Our 20-year preservation package includes: • Bi-annual automated lubrication cycles • Motor hibernation mode (<0.5W standby) • Remote diagnostics via IoT module

A: Yes - we adapt to QU120-QU180 rails with: • Rail mapping service (±0.5mm tolerance) • Custom end-trucks for legacy systems • Foundation reinforcement kits