SINOKO CRANES Europe type 5ton EOT crane designed strictly according to FEM standard, the key parts use the original imported, Bearing from SKF, NSK, Timken, electrics from Siemens and Schneider, motor and gear box are from ABB and SEW. Have the advantages of light self-weight, small space occupy, low cost running and maintaining, high performance, easy to operate, safety and reliable, eco-friendly technology, fast and easy positioning, safety monitoring, etc.

Structure of Europe 5ton EOT Crane

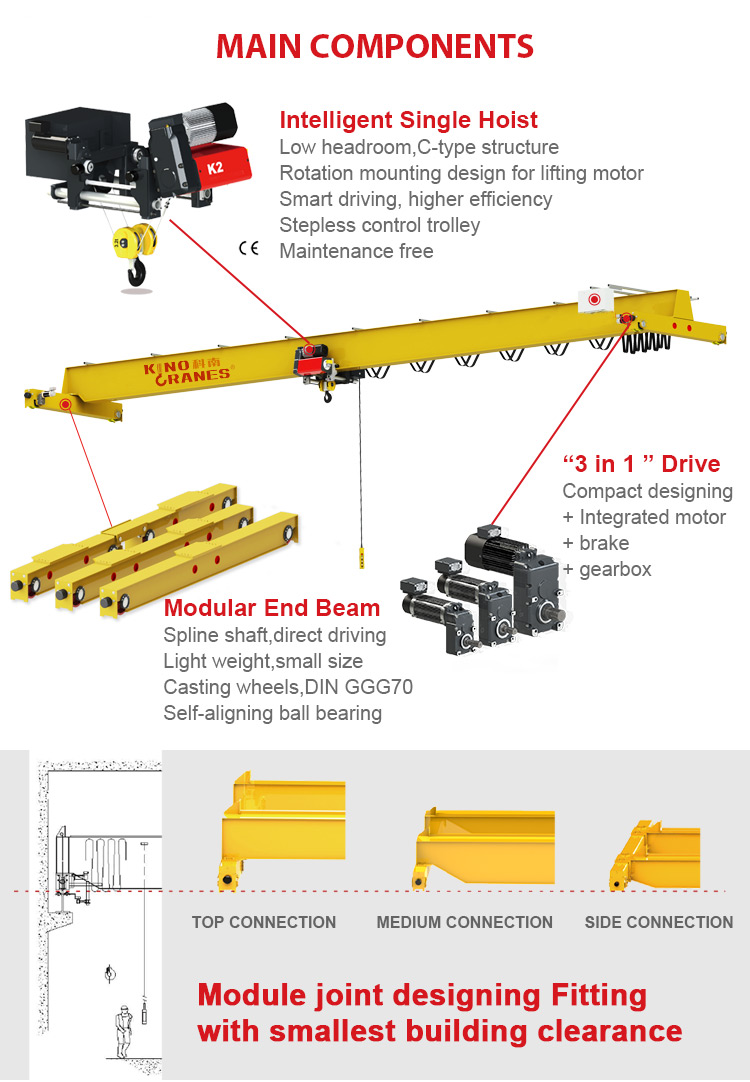

1. Main beam - The main traveling structure of the crane which spans the width of the bay and travels in a direction parallel to the runway. The bridge consists of two end trucks and one or two bridge girders depending on the equipment type. The bridge also supports the trolley and hoisting mechanism for up and down lifting of load.

2. End trucks - Located on either side of the bridge, the end trucks house the wheels on which the entire crane travels. It is an assembly consisting of structural members, wheels, bearings, axles, etc., which supports the bridge girder(s) or the trolley cross member(s).

3. Bridge Girder(s) - The principal horizontal beam of the crane bridge which supports the trolley and is supported by the end trucks.

4. Runway - The rails, beams, brackets and framework on which the crane operates.

5. Runway Rail - The rail supported by the runway beams on which the crane travels.

6. Hoist - The hoist mechanism is a unit consisting of a motor drive, coupling, brakes, gearing, drum, ropes, and load block designed to raise, hold and lower the maximum rated load. Hoist mechanism is mounted to the trolley.

7. Trolley - The unit carrying the hoisting mechanism which travels on the bridge rails in a direction at right angles to the crane runway. Trolley frame is the basic structure of the trolley on which are mounted the hoisting and traversing mechanisms.

8. Bumper (Buffer) - An energy absorbing device for reducing impact when a moving crane or trolley reaches the end of its permitted travel, or when two moving cranes or trolleys come into contact. This device may be attached to the bridge, trolley or runway stop.

Europe Type Single Girder 5ton EOT Crane Specification:

Item | 5ton Europe Design Single Girder Overhead Crane |

Main Electrical System | Schneider Brand |

Frequency converter/VVVF Drive | Schneider Converter |

Lifting mechanism | ABM/SEW Three in One Mechanism (Motor & Reducer & Brake) |

Travelling Mechanism | DONLY Three in One Mechanism |

Wire Rope | PFEIFER |

Wire Rope Safety Factor | 5 times |

Wire Rope Drum | Rolling Steel Plate |

Bearing | SKF / drum, hook set, pulley. |

Crane wheel | Forged type-42CrMo |

Travelling cable | High Temperature Resistance Cable |

Buffer | Black rubber buffer |

Power Source/ Control Voltage | 380V 50HZ 4P AC/48V |

Motor Insulation & Stator Protection | Class H & IP54 |

Working Temperature | 60℃ |

Cover Plate under Beam | Q345B |

Main structure Steel material | Q235 |

Painting | Shot blast Cleaning Dispose- 2 Grade, Epoxy Primer, Anti-corrosion Paint, Polyurethane surface painting |

Safety Feature | Lifting and travelling limit switches; Emergency Stop; Loss voltage protection; Grounded protection; Overload protection ;Short circuit protection; Overheating protection ; Over speed protection ;Over current protection; Faulted phase protection |

Advantages of Europe 5ton EOT Crane:

1). Compact design, optimal use of the work areas

2). Heavier loads, wider spans and higher working frequency

3). Control the load easily, position the load exactly

4). Superior safety and reliability

5). “One-Stop Shop” for your crane and hoist needs

Safety Measures of Europe Type 5ton EOT Crane

Overload protection; Main lifting motor with thermal protection; Hooks with latch; Rubber buffers; Protective earthing; Emergency switch; Sub-assemblies characteristic are tested before assembly. All cranes must be preassembled and tested before leaving factory and offer the certification of test

Production Display of Crane

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Our Europe-standard crane covers spans from 7.5m to 28.5m, optimized for workshop layouts. Custom spans available upon request.

A: Yes. The RF remote control complies with IP54 protection and FEM 1.267m safety standards, featuring anti-interference technology for hazardous environments.

A: Core parts include SKF/NSK bearings, Schneider/Siemens electrics, ABB/SEW motors, and PFEIFER wire ropes (5x safety factor).

A: Integrated protections: Real-time overload limiter, thermal motor protection, emergency stop button, dual-limit switches, and forged 42CrMo wheels.

A: Schneider’s variable frequency drive enables smooth start/stop, precise load positioning (±10mm), and 30% energy savings vs. conventional cranes.

A: Standard units ship in 4-6 weeks. Custom designs (e.g., special lifting height) require consultation – contact us for an instant quote.