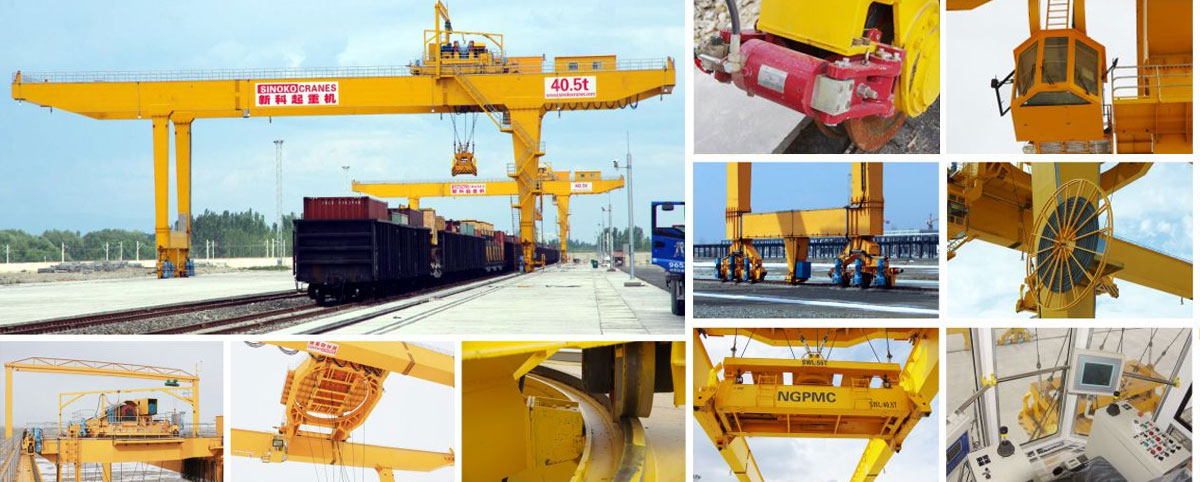

Sinokocranes' Rail Container Handling Gantry Crane is a specialized solution designed to meet the unique needs of container management. With this crane, moving, lifting, and positioning containers becomes an effortless task. It is engineered for high performance, providing a significant boost to operational efficiency and productivity in busy environments like ports, rail yards, and container depots.

The components of rail container handling gantry crane are mainly composed of the main beam, rigid and flexible door and legs, cross traveling, lifting mechanism, trolley operating mechanism, electrical system, driving room and other combinations.

Each part of the design and production are Sinokocrane personal new science and technology through repeatedly test and theoretical knowledge summed up, is what you need.

Sinoko rail container handling gantry crane according to different venues, container storage and transportation process and loading and unloading of vehicles, the spans normally be divided into some types as following: 22m, 30m, 35m.

Features

1. This crane can be used in inland terminals, container yard, rail freight station, coastal freight yard and frontier wharf.

2. Adopt dedicated container spreaders which can handle 20 feet, 40 feet and 45 feet containers.

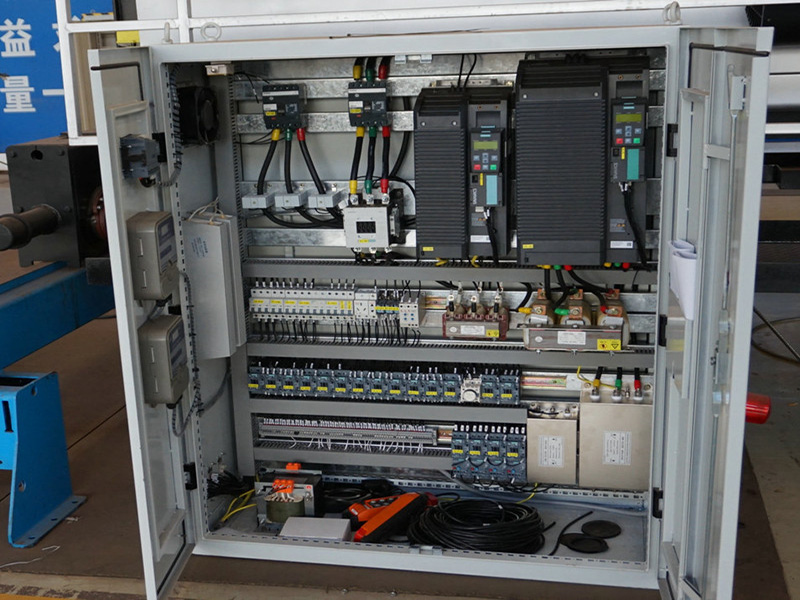

3. Electrical drive system is full digital AC frequency conversion, PLC control speeding, CMS intelligent monitoring and management system, the running state real-time monitoring equipment.

4. The upper trolley can rotate 270 degree for easy load and unload.

5. Three-in-one reducer is adopted for long travel and cross travel, easy maintenance.

6. Safety protection: Anti-breaking shaft, wind warning, anti-tipping, etc.

Specification

| Model | LJ25/40-23 | Light Typre LJ40-23 |

| Lifting capacity(without spreader)(T) | 35,40 | 40 |

| Work level | A7,A8 | A6,A7 |

| Span(m) | 23.47 | 23.47 |

| Lifting Height(m) | 12.2~17.8 | 16.5 |

| Stack layer | 3/4~5/6 | 5/6 |

| Containter size | 20'40'45' | 20'40'45' |

| Spreader rotation angle | ±5° | ±5° |

| Lifting(m/min) | 13/26,23/52 | 12/18,18/28 |

| Trolley travelling (m/min) | 50,70 | 24 |

| Crane travelling (m/min) | Full load-90 no load-130 | Full load-20, no load-40 |

| Max. wheel load (kN) | 310 | 310 |

Container Gantry Cranes Showing

CASE

Looking for an efficient container lifting solution? Our European Standard Container Lifting Crane is designed for high-performance lifting in busy ports and logistics centers. Explore our case studies showcasing how we've customized cranes to optimize container handling and boost operational efficiency.

Pakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a Quote40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a QuoteFAQs

A European Standard Container Lifting Crane is designed to handle the lifting and transportation of containers, especially in ports, warehouses, and logistics facilities. This crane is optimized for efficient, safe, and fast lifting of containers with precise control.

Sinoko’s European Standard Container Lifting Crane incorporates advanced engineering for reliability and performance. It offers high lifting capacity, precise control, and energy-efficient operation. Its European design ensures safety, stability, and durability for handling heavy containers in busy ports and terminals.

Yes, Sinoko provides customization options for the European Standard Container Lifting Crane. You can modify key specifications like lifting height, span, hoist capacity, and power configurations to meet your specific operational needs, ensuring the crane is perfectly suited to your requirements.

Sinoko prioritizes safety in all of its cranes. The European Standard Container Lifting Crane features safety mechanisms such as overload protection, limit switches, anti-sway technology, and emergency stop functions, ensuring secure operation in busy and high-demand environments.

European Standard Container Lifting Cranes are widely used in industries such as port and terminal operations, shipping logistics, and warehousing. They are essential for efficiently handling containers, improving productivity in containerized cargo operations across various industrial sectors.

To receive a quote for the European Standard Container Lifting Crane, simply contact our sales team with your project requirements, including lifting capacities, customization needs, and operational conditions. We’ll provide a tailored solution and competitive pricing based on your needs.