Soft start twin girders gantry crane are generally used for project installations, such as large-scale equipment, but require extensive space. Normally they are used for heavy lifting of goods. Its structure, as the word said, is like a gantry, the track is tiled on the ground, the old-fashioned motor at both ends, drag the crane to move back and forth on the track, many of the gantry type in order to install more accurate, but also the use of variable frequency motor and Servo drive.

With a lifting capacity ranging from 5 tons to an impressive 500 tons, the Sinoko Twin Girder Gantry Crane provides the strength and reliability you require for your material handling operations. Trust in its robust construction and advanced design to optimize your productivity and efficiency.

Features

1. The gantry adopts the box type double beam welding structure, which increases the working space and facilitates transportation, installation and maintenance.

2. The use of special-shaped rails and flexible cables for conducting electricity in the trolley.

3. Parts standardization, serialization, generalization.

4. The gantry crane has the power cable reel type and slide contact type, which can be selected by the user.

5. Control room vision, control operation flexibility, work comfort. Fans, air conditioners, walkie-talkies, etc. may also be added upon request.

Specification

| Type | MG |

| Lifting Capacity | 5t~500t |

| Lifting Height | 3~60m |

| Span | 12~35m |

| Working Duty | M3-M8 |

| Ambient Temperature | -20~40℃ |

Inquiring Parameters Needed

1.The capacity

2.Span (track center to guide rail center).

3.Lifting height (hook center ground).

4.Is it necessary to hang outside (please provide the outside length).

5.Need rails and cables? (Please provide the run length).

6.Other special requirements for gantry cranes (work environment, dimensions).

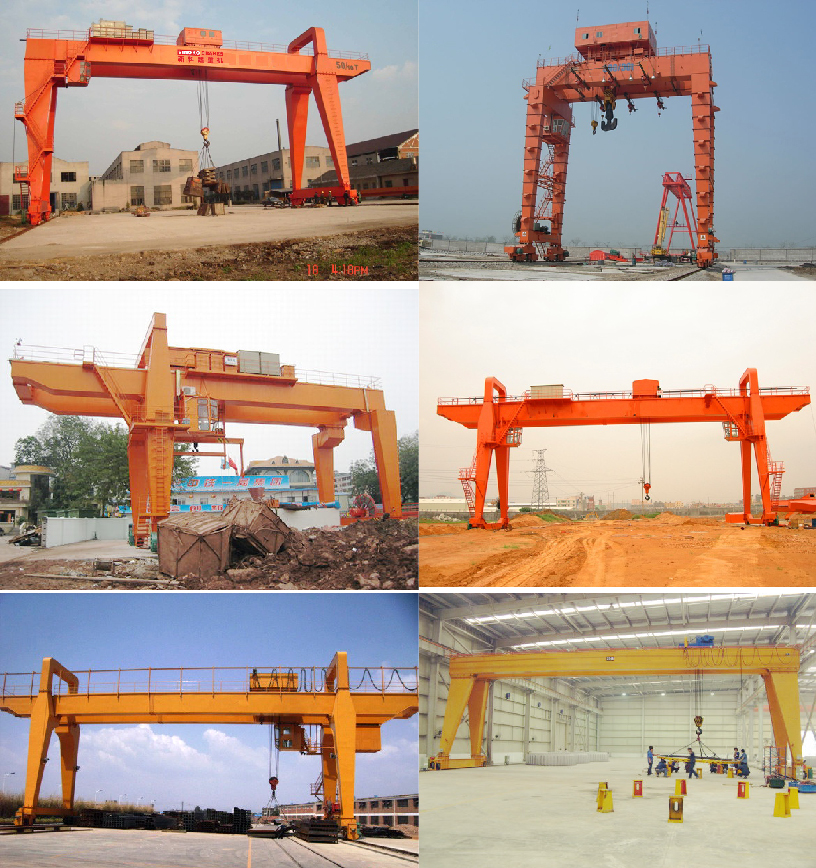

Our Related Gantry Crane Cases

Upgrade your lifting capabilities today with the Sinoko Dual Girder Gantry Crane. Experience the benefits of enhanced capacity, durability, and adaptability for your specific requirements. Contact us now to learn more about this exceptional crane and how it can transform your operations.

CASE

The gantry crane overcomes the challenges of space limitations and extreme environments, thereby enhancing industrial production efficiency - it can lift heavier objects, reach greater distances, and operate in a more intelligent manner.

Pakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a Quote40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

Standard orders ship in 14-16 weeks.

Handles heavier loads (up to 500 tons) and lasts longer in tough conditions. Perfect for daily heavy lifting in factories or ports.

Yes! Handles -20°C to 40°C temperatures.

Three key protections:

Automatic stop at 105% overload

Emergency cut-off switches

Travel limiters to prevent collisions

Flexible footprints:

→ Width: 12-35m span options

→ Height: Clears most workshop doors

→ Ground: Level concrete or steel rails

Just monthly checks:

1.Grease wheel bearings

2.Inspect wire ropes

3.Test safety switchesFree video guides included