Overview:

Mold Load Turning Machine is designed for safe lifting and turning of inherent loads with nearly round or square cross -section. Especially suitable for heavy and bulky goods, such as machine components, welded frames, mould boxes for foundries, concrete precast parts

Features

Mold Load Turning Machine increases operational safety and productivity. Auto load balance system is to adjust synchronously and asynchronously. The max. carrying capacity is up to 130ton.

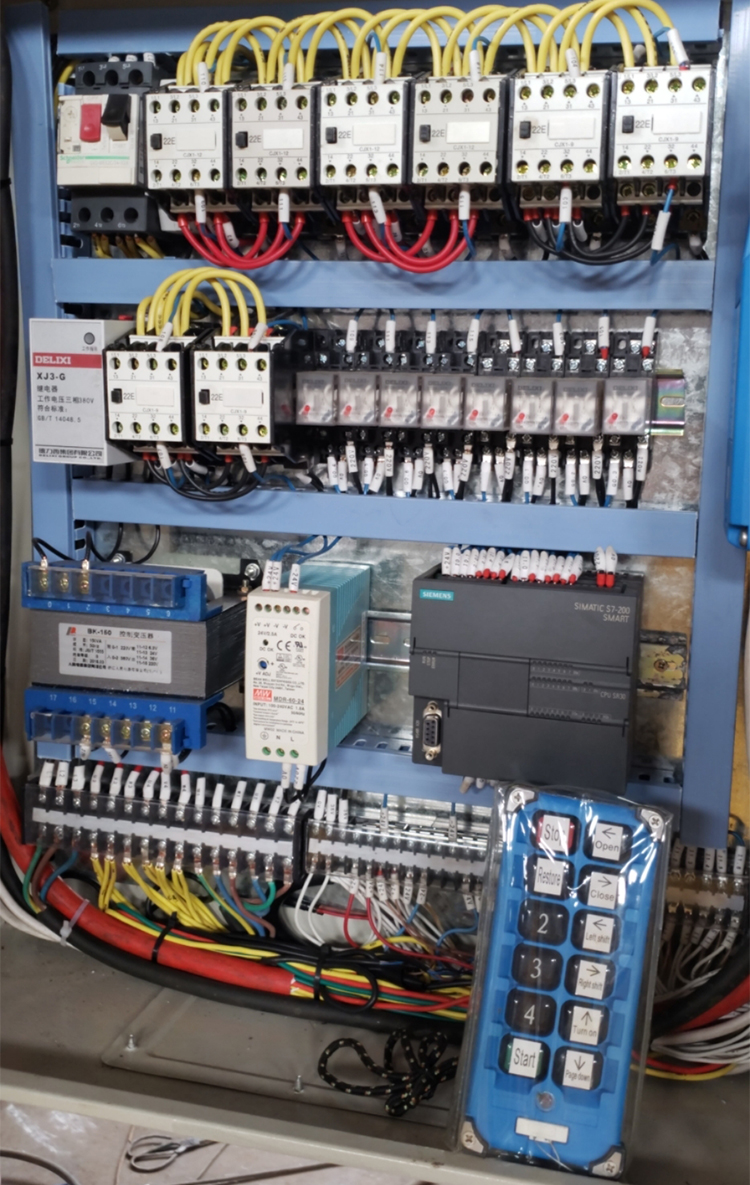

Electric panel of Mold Load Turning Machine

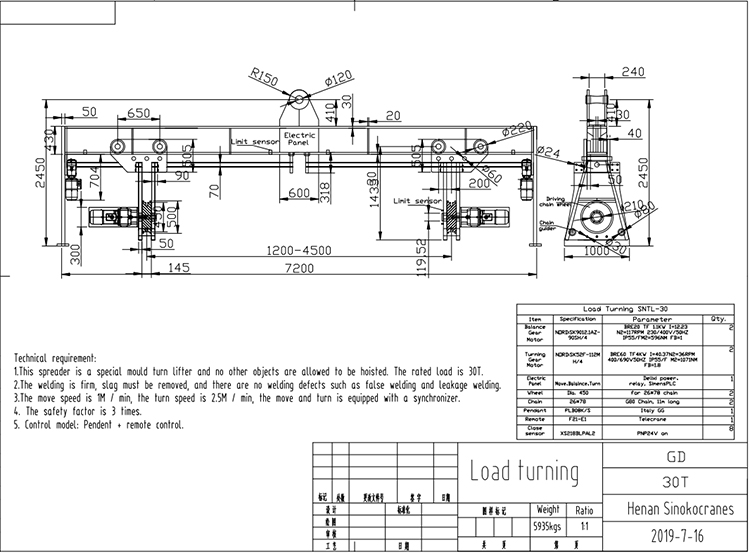

Standard design of Mold Load Turning Machine

1. | Suspension Frame | It is suitable for single crane hooks according to DIN15401 |

2. | Safe Turning Equipment | The overturning procedure can be stopped at any time and in each position by emergency stop |

3. | Driving Adjustment System | Two roller are driven by an electric motor, and available to run in synchronism. |

4. | Emergency Stop Operation | Radio remote control with automatic belt or chain cut-off to prevent the belt lock from driving through the rollers |

5. | Electric Panel Control with PLC | The electric panel control is completely wired in the switch box and with plug for the connection to the crane facilities without spring cable reels. |

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Installation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

A: Ideal for rotating heavy, bulky items with round/square cross-sections up to 130 tons – including molds, machine components, concrete precast parts, and welded frames.

A: Triple safety systems: Emergency stop at any position Automatic belt/chain cut-off PLC-controlled synchronization

A: Yes. Features DIN15401-compliant suspension frames and plug-in wiring for seamless integration with overhead cranes.

A: Essential for: Foundries & mold manufacturing Precast concrete production Heavy equipment fabrication Automotive/industrial component handling

A: Dual electric motor-driven rollers with synchronized/asynchronous adjustment via radio remote control (included).

A: Full 360-degree rotation capability with precise positioning control.