Overview:

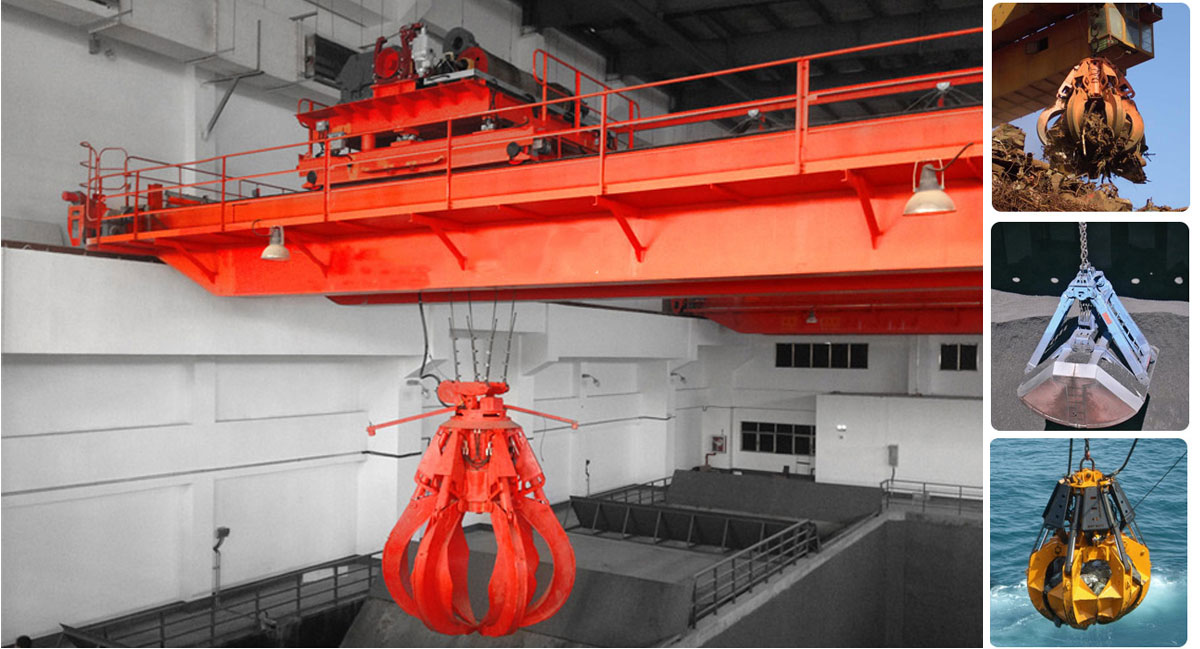

QZ Grab Bucket Overhead Crane is mainly compriesd of box-shaped girder, End Carriage, Lifting Trolley, Grab bucket and Electrical control system. Generally, the power supply System for trolley and crane are festoon system and Bus Bar system.

Type:QZ

Lifting Capacity: 5~25t

Lifting Height: customized

Span:10.5~34.5m

Working Duty: A6

Ambient Temperature: -20~40℃

Features

1). Reasonable structure, strong bearing capacity

2). Low noise, soft starting and stopping

3). Safe and reliable operation

4). Commodious cabin and open view

5). Low cost maintenance, long working life

6). Strong box type,welding by machine hand.

7). Wheels are vacuum casting,medium frequency quenching

8). Wheels, wirerope drum, gears, couplings are processed by CNC manchine center, TOP quality control.

9). Heavy duty slipring motor,Or Sq.cage motor with VVVF, IP54 or IP44,insulation class F or H,soft starting and smooth running.

10). Siemens or Schneider main electric parts are used for durable and safe operation

Specification

| Items | Unit | Capacity | ||||

| Lifting Capacity | t | 5 | 10 | 16 | 20 | |

| Span | m | Max to 31.5 | ||||

| Working class | A6 | |||||

| Speed | Hoist | m/min | 40.1 | 40.7 | 41.8 | 48.6 |

| Trolley | 44.6 | 45.6 | 41.8 | 48.6 | ||

| Crane | 93.7 | 86.4 | 76 | 89 | ||

| Motor | Hoist closing | Kw | YZR225M-8/22*2 | YZR280S-10/37*2 | YZR315M-10/75*2 | YZR355M-10/90*2 |

If you're interested in our QZ Overhead Crane, please contact us for a quote. We'd be happy to discuss your specific requirements and provide you with a solution that meets your needs.

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: Engineered for high-volume granular materials including: • Aggregates (gravel/sand up to 2,500kg/m³ density) • Grain/cereals (≤18% moisture content) • Coal/ore with ≤50mm particle size • Custom grabs for fly ash or sludge available

A: Our Schneider VVVF system delivers: • ±50kg precision control during grab closing • Energy savings up to 35% vs contactor cranes • Anti-sway algorithm for ≤3° swing at 48m/min

A: Dual certifications: • ATEX Zone 22 compliance (dust explosion protection) • IP54 hoist motors with thermal cutoffs • Optional anti-spark grab buckets for coal handling

A: Yes. Arctic package includes: • Siemens S7-1200 PLC with cold-start assist • -40°C rated hydraulic fluid for grab mechanisms • Heated cabin/remote controls standard

A: Predictive maintenance system: • 8,000h bearing life on trolley drives • Self-lubricating polymer bushings • Remote diagnostics via IoT module (optional)

A: 15-day lead time for: • Clamshell sizes: 0.5-8m³ capacity • Specialized grabs: Orange peel/electro-hydraulic • All grabs feature Hardox 450 wear plates