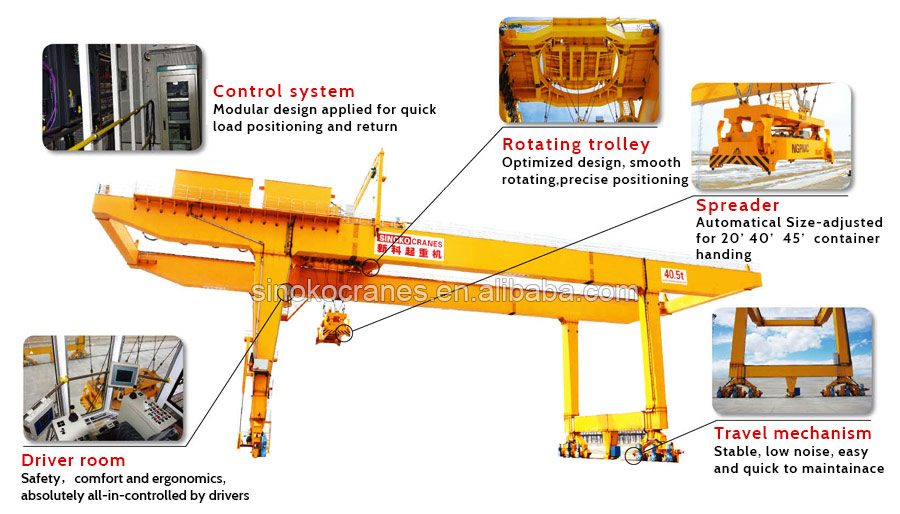

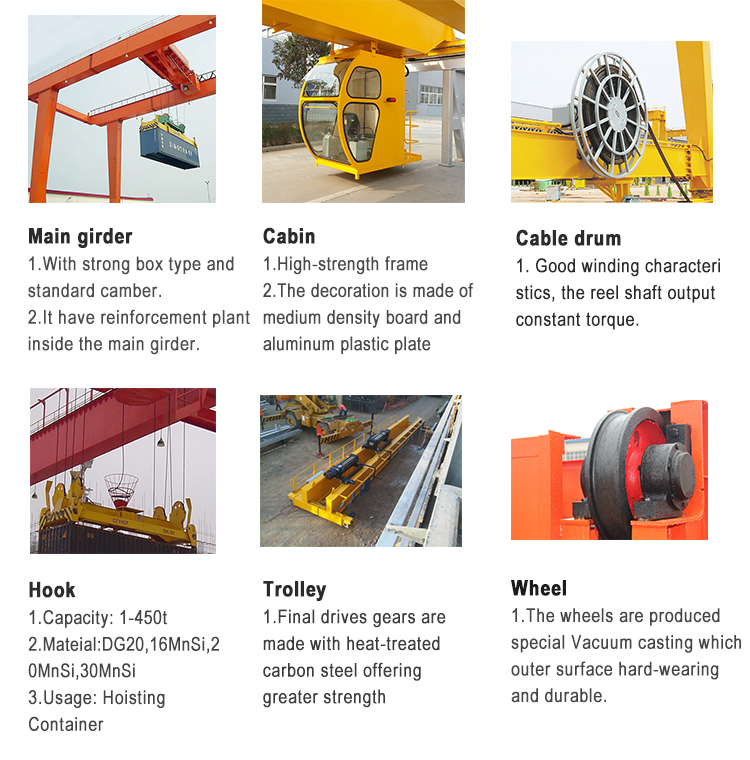

Container gantry cranes is a specialized container handling machine that is applicable in container yard, railway container terminal, to handle international standard containers.

Container gantry cranes can travel on rail by means of the yard power, usually powered by cable and cable drum, to lift and stack containers in the yard area with the equipment of the 20' or 40' or 45’ telescopic spreader (or twin-lift spreader if needed).

Features

1) Simple structure in linear type ,easy in installation and maintain.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

Specification

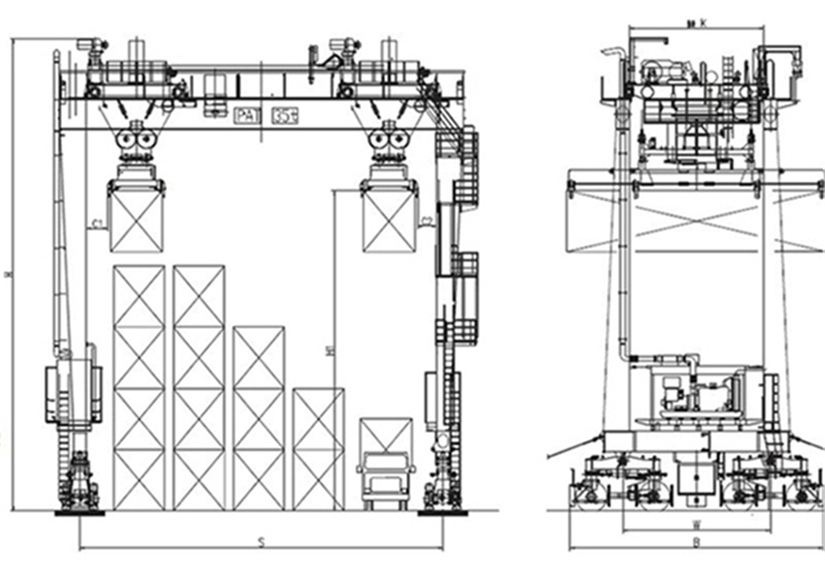

Capacity | Under spreader 35tons |

| Duty Class | A6~A8 |

| Span(rail to rail center) | 30m or as required |

| Material handling | 20’ 40’ 45’container |

| Cantilevers | According to your demand, but not more than 1/3 of span |

| Lifting height | 16m or as required |

| Spreader | 20; or 40; or 45’ telescopic spreader |

| Lifting speed(m/min) | 0~20 |

| Cross travelling speed(m/min) | 0~30 |

| Long travelling speed(m/min) | 0~40 |

| Power source | AC 380V 50HZ 3Ph (or other standard) |

| Control model | Cabin |

| Max.wheel pressure(KN) | 290 |

| Rail model | QU80 |

CASE

At Sinoko Crane, we believe the best way to demonstrate the quality and reliability of our container gantry cranes is through real project success. Our gantry crane systems are helping customers around the world streamline operations, increase lifting efficiency, and reduce downtime. Browse our featured project cases below to see how Sinoko delivers customized, high-performance solutions for a wide range of industries and working environments.

Pakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a Quote40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

Sinoko provides a variety of container gantry cranes—including rail‑mounted and rubber‑tyred models, single or double girder, portable, semi‑gantry, RMG, and container stacking versions—designed for port yards, railway transfer areas, and large private container yards.

Yes—Sinoko specializes in tailored solutions. They design container gantry cranes with rotating trolleys, integrated operator cabins, and structural adaptations to meet your capacity, span, and site‑specific requirements.

Sinoko offers a full spectrum of capacities, from light-duty cranes around 10 tons up to heavy-duty systems exceeding 100 tons, covering needs across various industrial and port environments.

Sinoko’s container gantry cranes serve global clients—including the Middle East, South America, and North America—and come with comprehensive support like OEM/ODM services, factory tours, onsite installation supervision, and maintenance assistance.

Sinoko’s manufacturing adheres to international standards with certifications including ISO 9001 for quality, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety, ensuring reliable performance and heavy‑duty durability.

Lead times vary depending on season: during peak periods, turnaround is about one month, while in off‑peak seasons, delivery can be arranged within approximately 15 working days.