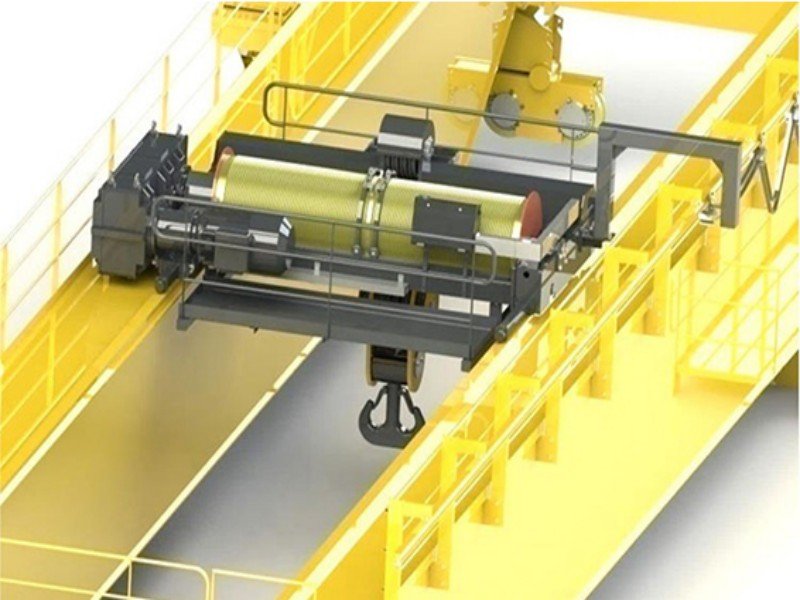

The Sinokocranes Brand FEM Standard Electric Open Winch Trolley for Overhead Crane is an ideal material lifting equipment applied in steel mill, paper mill, general manufacturer, power plant, port, petro-chemical, aerospace, non-ferrous industries, army, mining and oil fields, offshore platform, shipyard, car makers, waste-to-energy factory, nuclear etc.

Features

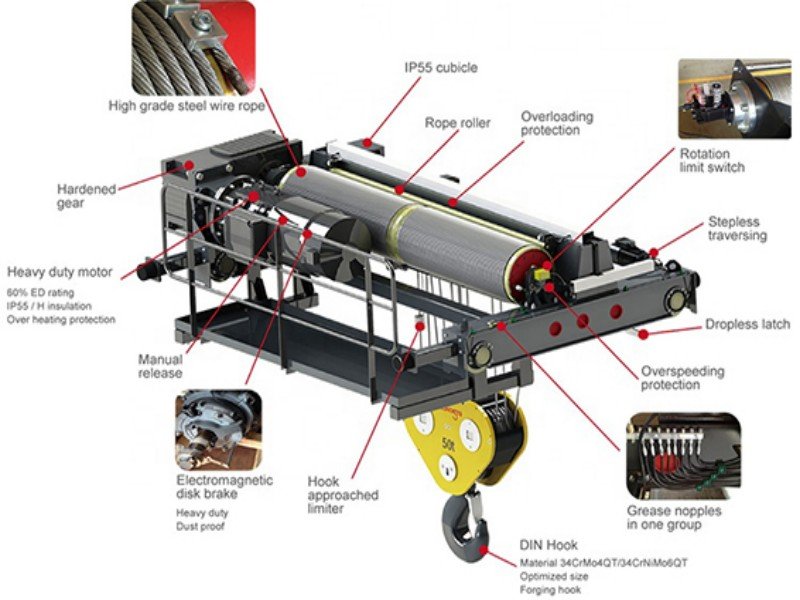

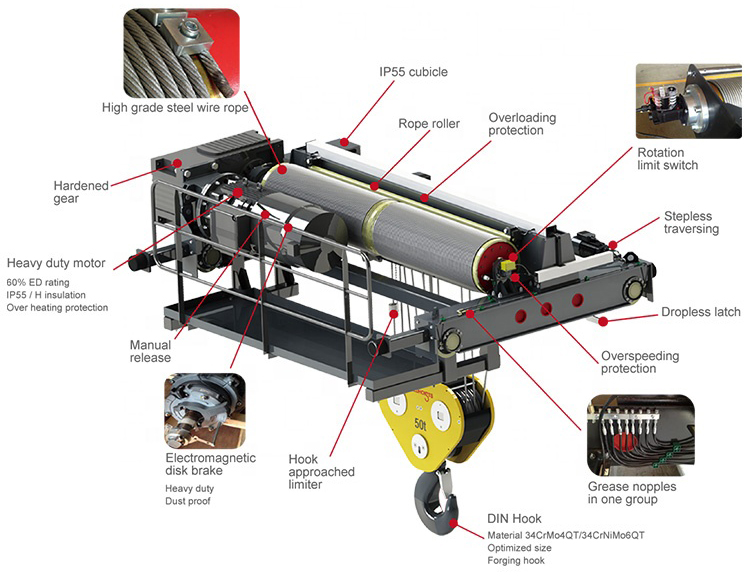

1. | Lifting motor | Heavy duty motor 60%ED rating Variable frequency motor Over heating protection |

2. | Lifting gear box | CrNiMo alloy harden gear(HRC60) Side hanging design |

3. | Lifting brake | Double brake type available Electric magnetic brake inside Electric hydraulic thruster type with ZPMC brand |

4. | Reel | Reliable rope guider & anti-deflection High strength galvanized steel wire rope 2160N/mm2 Heavy blocks densely covered to avoid wire rope loosing |

5. | Hooke Assembly | 34CrMo4QT/34CrMo6QT, Optimized size Forging hook |

6. | Electric panel | IEC standard testing Schneider brand or as required Aviation plug no wiring connection at user’s site |

7. | Smart function | 2-step adjustable rotation limit switch Hook approached limit switch Grease nipples in one group Dropless latch Over speeding protection Inching / Micro-speed / Anti-sway / brake-open holding function HMI and safety monitoring system |

Specification

CASE

Check out our project case studies to learn how Sinoko electric winches are trusted in bridge and gantry cranes across various industries for safe, efficient, and reliable heavy-duty lifting operations.

Installation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a QuotePakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteFAQs

It features a compact, lightweight structure with low headroom, hardened gearbox, and stepless control for smooth operation—making it ideal for space-limited industrial applications.

Advanced safety controls include real-time monitoring, adjustable rotation limit switches, anti‑sway and overspeed protection, dropless latch, inching/micro‑speed modes, and hook‑approach sensors.

Models range from 10 t (JK1) to 80 t (JK8), with lifting speeds around 22 to 30 m/min and rope capacities spanning approximately 100 to 250 m.

It’s ideal for demanding sectors including steel mills, paper and manufacturing plants, power and petrochemical facilities, ports, aerospace, shipyards, automotive factories, mining operations, oil & gas sites, nuclear facilities, and waste-to-energy plants.

The design emphasizes standardized modular components and easy accessibility, enabling highly stable performance and simplified maintenance routines.

Yes—Sinoko supports customization, and similar open winch designs can be tailored from 5 t up to 500 t for diverse applications.